Dassault Systèmes

175 Wyman St.

Waltham, MA 02451 US

800-382-3342 | 201-675-8361

3ds.com/products-services

About Dassault Systèmes

Provides businesses and people with virtual universes to imagine sustainable innovations. Delivers a complete set of process-oriented applications to design, simulate and manufacture composite structures on a single, virtual platform.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Dassault Systèmes Supplies the Following Products

- 3D printing

- CAD/CAM/CAE design

- CAD/CAM/CAE hardware/software

- Consulting, process development

- Education/Training

- Finite element modeling/analysis (FEM/FEA)

- Kitting equipment and software

- Materials analysis

- Nesting software

- Other additive manufacturing

- Other services

- Product design

- Projection/alignment systems, laser

- Regulatory compliance

Editorial, News, and Products

-

SPE ACCE welcomes students to submit poster competition abstracts

The ACCE provides students with a chance to present their work in composites to industry experts. Posters are due July 1, 2024.

-

Designing and manufacturing turbine test nacelles

Michigan-based Ground Test Solutions (GTS) shares the design and manufacturing processes involved in building composite nacelle components used in testing jet and helicopter engines.

-

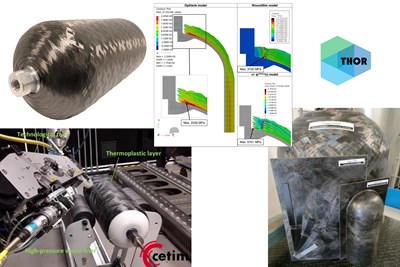

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

-

RTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

-

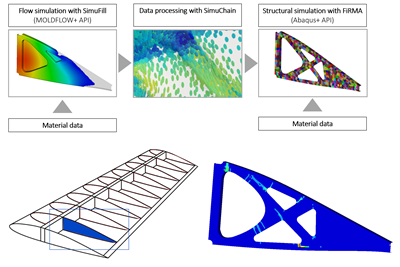

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

-

DOE funds project for 3D-printed wind blade tooling

Targeting U.S. wind energy, the program backs Purdue’s CMSC center and industry partners to develop the foundation for automated tooling manufacture, supporting new innovations in composite materials, other technology elements.

-

Submit abstracts to SPE ACCE 2023 student poster competition

Graduate, undergraduate, community college and high school students are invited to submit poster titles and abstracts on innovative composites technologies by July 1, 2023.

-

Demonstrating functionalized, cost-effective composites using additive extrusion

Hybrid thermoset/thermoplastic composite part with 3D-printed functionalization demonstrates technology possibilities and EmpowerAX open platform offering expertise from members throughout the process chain.

-

Optimizing AFP for complex-cored CFRP fuselage

Automated process cuts emissions, waste and cost for lightweight RACER helicopter side shells.

-

Plant tour: Avel Robotics, Lorient, France

From AFP hydrofoils to more efficient aircraft parts, Avel uses digital design, multiprocess production and a rule-breaking approach for complex 4D composites.

-

CFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

-

Plant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

-

Digital design, multi-material structures enable a quieter supersonic NASA X-plane

NASA’s composites-intensive X-59 QueSST experimental aircraft is set for its first flight by the end of 2022, after nine years of design, manufacture, assembly and testing by Lockheed Martin Skunk Works.

-

Improving analyses of composite pressure vessels

Accurate geometry modeling and equivalent material property approximations captured by WoundSim will play a role in improving COPV analyses.

-

WoundSIM software tool simplifies design and simulation of composite pressure vessels

Rapid and efficient tank design process is achieved via an integrated FEA software translator, advanced parametric optimization, simulation and load case testing and post-processing capabilities.

-

Purdue University composites center opens large-scale additive lab, seeks consortium partners

Purdue’s Composites Manufacturing and Simulation Center (CMSC) cut the ribbon on the Thermwood LSAM Research Lab, which partners can access with Purdue’s ADDITIVE3D simulation module.

-

IACMI Members Meeting reconnects members, discusses road ahead

Oct. 5-7 in Detroit, Institute for Advanced Composites Manufacturing Innovation (IACMI) members presented automotive R&D and discussed industry trends.

-

Industrial-scale wave energy system enabled by mobile filament winding

Sweden-based CorPower Ocean designed its 9-meter-long, filament-wound GFRP buoy prototype for high-efficiency, durable wave energy generation and fast, on-site manufacture.

-

Using machine learning to accelerate composites processing simulation

A speed gain of 1,000 to 10,000 times greater than traditional FE models has been achieved using machine learning models, enabling near real-time simulation for large composite components.

-

Challenges, opportunities when designing for fiber-reinforced AM

Bridging the gap between as-designed and as-made, and where do you put the fiber?

-

Speeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

-

Design innovations improve efficiency of composite medical table

WIT-Composites' efforts to design a more effective all-composite surgical table led to development of complex components and an elastic carbon fiber material.

-

Solvay, Vertical Aerospace expand on UAM agreement

Composite materials supplier Solvay Composite Materials and urban air mobility (UAM) manufacturer Vertical Aerospace offer details about materials, process use in VA-1X aircraft.

-

Hydroelectric turbine blade design propelled by composites

Glass fiber composites power the development of a modular, spiral-shaped hydroelectric micro turbine blade for low-cost, high-efficiency renewable energy generation.

-

Dassault Systèmes, Purdue establish center of excellence

The 3DEXPERIENCE Education Center of Excellence in Advanced Composites at Purdue University aims to educate the next-generation workforce and accelerate Industry 4.0.

-

Next-generation composites qualification

Fully digital qualification hasn’t yet arrived, but simulation and analysis software continue to evolve and work together with physical testing practices.

-

Building the Museum of the Future

FR composite panels provide structure, sealing and iconic facade for pioneering architecture in Dubai.

-

C-FREX exoskeleton depends on CFRP for unpowered movement

C-FREX uses a novel design and CFRP to overcome the heaviness and weakness of metallic exoskeletons.

-

Composites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

-

Composites 4.0: Architecture and ontology

Adaptive systems, IoT platforms and apps, the need for 4.0 standardization and a new way to develop and certify composite aerostructures.

-

Coriolis Composites and Edixia develop inline inspection for AFP

Video and discussion of how the sensor and software operate to boost composites productivity

-

Dassault Systèmes, Rize Inc. partner to provide composite 3D printing solutions

Customers will be able to integrate Rize 3D printing technology with Dassault’s 3DEXPERIENCE software platform.

-

VR system now compatible with 3DEXPERIENCE platform

VRgineers’ XTAL virtual reality (VR) system is now compatible with Dassault Systèmes’ 3DEXPERIENCE platform.

-

Increasing access to AFP

Addcomposites is democratizing composites manufacturing by leasing a low-cost toolhead that turns any robot into an automated fiber placement machine.

-

Evolving into continuous fiber reinforcements

SABIC expanded its materials offerings in short-fiber injection and long-fiber thermoplastic (LFT) materials to include continuous-fiber thermoplastic tapes.

-

Boom Supersonic announces plans for XB-1 demonstrator roll-out

The company says it will complete its XB-1 supersonic aircraft demonstrator by December, with flight tests next year.

-

Composites-focused engineering, simulation services company launches in Germany

Simutence GmbH, a company started by Karlsruhe Institute of Technology graduates, offers custom simulation methods to composites manufacturers across end markets.

-

IACMI to host training workshop with Composites One, Closed Mold Alliance

The workshop will be held at the Composite Prototyping Center on June 11-12, 2019.

-

Continuous Composites, Spatial partner to advance composite 3D printing

As part of the partnership, Continuous Composites will use Spatial Corp.’s 3D software to advance its robotic continuous-fiber 3D printing technology.

-

Skeleton design enables more competitive composite autostructures

New approach combines thermoplastic pultrusions with injection overmolding in a two-step, 75-second process.

-

Airbus and Dassault Systèmes partner on digitization and 3D design for next-generation aircraft

Airbus will deploy Dassault Systèmes’ 3DEXPERIENCE platform with the aim of enabling digital design, manufacturing and services (DDMS) across all Airbus divisions and product lines.

-

Thermoplastic door a first for automotive composites

A team of automotive researchers are engaged in a four-year project with goals of building a lighter, 100% recyclable, carbon fiber-reinforced thermoplastic door.

-

Advancing composites through virtual and augmented reality

A review of technologies that are bridging the technical divide between the virtual world of design and simulation, and the real-world of composites manufacturing and repair.

-

Teaming to define what automotive CFRP could be

Ford and Magna explore a high-volume chassis front subframe build from co-molded chopped fiber and noncrimp fabric SMC.

-

Generative design and continuous 3D fiber deposition

Generative design replicates nature’s evolutionary approach by combining artificial intelligence (AI) and cloud computing to provide thousands of solutions to one engineering problem.

-

People on the Move: May 2018

CW’s monthly roundup of people on the move in the composites industry.

-

MultiMech 18.0 features improved accuracy and speed

MultiMech 18.0 empowers engineers to perform faster, smarter and more realistic analysis of composites.

-

Composites-intensive folding bike: Simplifying multi-modal transportation

The world’s lightest folding bike relies on CFRP for high stiffness and strength at low weight.

-

McNair Aerospace Center: Closing the composites education gap

As the composites industry in South Carolina continues to expand through Boeing and its tier suppliers, composites education follows suit through the McNair Center.

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

Zero-defect manufacturing of composite parts

ZAero project aims for 30-50% boost in productivity via inline AFP inspection, simulated part performance and decision support tools.

-

Composites and Industry 4.0: Where are we?

As the tide of the Fourth Industrial Revolution rolls in, how will composite manufacturers ride the wave?

-

Reconfigurable tooling: Revolutionizing composites manufacturing

Shape-changing molds eliminate tooling for large 3D panels while automated assembly fixtures go modular, using metrology to reduce cost and shimming.

-

Lightweighting speed into CNC machining

Drawing on a long history in composites manufacturing and CNC machining, this innovator turns to carbon fiber composites to reduce gantry component weight and increase shaping efficiency.

-

Variable-axial composites open path to lighter composite structures

CFRP recurve bow riser demonstrates design and manufacturing approach with potential to cut weight vs. aluminum by 50-75% while increasing strength and stiffness.

-

Software shortens design path to longboard

Materials information program helps optimize materials selection.

-

Automated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

-

RTM-based redesign advances safety for one-of-a-kind wind tunnel

Glass fiber and honeycomb spacers between compressor blades get upgraded to a higher factor of safety with less weight using solid carbon fiber and RTM.

-

Composite submersibles: Under pressure in deep, deep waters

Manned deepsea exploration calls for a highly engineered composites solution that saves weight and preserves life — at 6,500-psi service pressure.

-

Collaboration produces winning paddleboard

Design, and design for manufacturability, come together in this racing SUP for one-off and serial production.

-

Machine vision: Rapid error detection

Aerospace-aimed ply placement technology evolves into process management and near-real time inspection system for production laminated composite parts.

-

Carbon composite driveshaft: Tailorable performance

This racing and aftermarket specialist designs and produces custom driveshafts for multiple markets.

-

3D knitting solves preforming cost, time

Disruptive digitized technology a dramatic step-change in near-net preform production for Dassault Falcon interior air duct.

-

Increasing the industrial adoption of composites additive manufacturing

The additive manufacturing industry has challenged the design community to develop an efficient product engineering platform where the barriers between design, optimization and simulation would be broken and optimized parts could be explored in the design environment.

-

Clear Carbon & Components: Bristol, RI, US

Breaking barriers in process and complexity, this agile manufacturer is gaining renown as a composites problem solver and champion of Class A cosmetic surfaces.

-

Carbon fiber meets simulation in ultralight bike frame

Rolo Bikes wanted to design a bicycle frame with carbon fiber in mind, and it wanted test it in the virtual world.

-

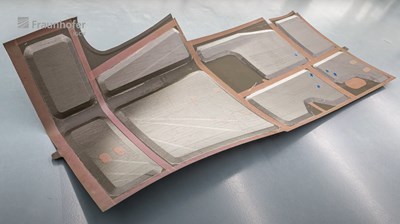

Fiber patch preforms help tailor kiteboard performance

Automated means for laying fiber only where needed offers new potential to fine-tune torsional stiffness and flexibility to board and rider styles.

-

World’s largest center console with single-skin hull

Navy RHIB concept goes commercial in the new HydraSports Custom Sueños high-performance offshore fishing boat.

-

Classic harps in carbon fiber

Lever and pedal models less cumbersome, still classy.

-

Hybrid analysis: Making the most of FEA by leveraging traditional analysis

CW guest columinst Collin Petersen (Janicki Industries, Sedro-Woolley, WA, US) suggests the use of more traditional analysis methods, where it is sensible to do so, making your finite element analysis (FEA) significantly simpler in the process.

-

Optimizing composite aerostructures production

Israel Aerospace Industries ramps production while reducing costs and improving quality thanks to integrated optimization software.

-

Automotive front axle: A glass act

The development of glass-fiber reinforced car axle is a sign of the new, expanded role composites will play in the design of future automobiles.

-

Composites extend service of oil and gas pipelines

Corrosion-resistant aramid fiber/thermoplastic liner gives new life to deteriorating steel subsea pipelines.

-

Thermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

-

Understanding the influence of fiber orientation on structural analysis of fiber-filled parts

The effect of fiber orientation on material properties is a key way the injection molding process impacts mechanical performance. Doug Kenik and Angie Schrader of the Design, Lifecycle & Simulation product group at Autodesk (Waltham, MA, US) illustrates two ways fiber orientation influences the structural behavior of fiber-filled parts and discuss the need for a bi-directional approach to design and analysis.

-

Laser projection: Envisioning more than templates

Advanced systems offer ply-placement verification, aids to faster assembly and manufacturing process and quality control.

-

CFRP camera boom enables safe spill inspection

NONA Composites’ 32m REACH structure meets tight remediation schedule at DoE radioactive waste storage site.

-

Modeling and simulation: Is ICME the next composites breakthrough?

CompositesWorld columnist and composites industry consultant Dale Brosius encourages empirical learners (read "hands-on, trial-and-error old-timers") like himself to buy in and start using today's software-based design and simulation tools, which, he says, have the "potential to truly transform the composite industry."

-

Resin infusion produces autoclave-capable tools for Scorpion jet

Leading Edge Aerospace designs and builds cost-effective prototype tools for maverick military aircraft concept.

-

Software Update: Simulation saves

A look inside the increasingly well-equipped virtual toolbox for composite design, analysis, and manufacturing.

-

3D Printing continuous carbon fiber composites?

Additive manufacturing startup MarkForged aims to make it happen and is already marketing systems.

-

Don’t call it a blimp!

The builders of this variable-buoyancy craft count on carbon fiber/epoxy trusswork to enable a new era of air transport.

-

SAMPE Tech Seattle 2014 Preview

The Society for the Advancement of Material and Process Engineering’s annual fall Tech conference is now a spring event.

-

Demonstration software modeling exercise aids Taiwan’s yachtbuilding community

Ray Tsai, technical director of Simutech Solution Corp. (Taipei, Taiwan) and colleagues develop a demonstration modeling exercise for Taiwanese motoryacht builders.

-

An Internet aid for acceleration of aerospace composites certification

Guest columnist Rani Richardson, a CATIA composites product specialist at Dassault Systèmes (Waltham, Mass.), proposes a way to speed certification of aerospace composites.

-

Thermoplastic composites save weight in rotorcraft aerostructure

This helicopter structure outdoes both metal and thermoset-composite alternatives.

-

Main landing gear doors designed for all contingencies

For the Airbus XWB airliner, they must meet strict structural, aerodynamic, emergency and aesthetic requirements.

-

Composites repair

As more composite materials find a place on aircraft, boats, bridges and hundreds of other applications where part replacement is both difficult and expensive, OEM engineers are considering the repairability of structural and secondary composite components during the initial design phase of a project.

-

Nondestructive inspection: Better, faster and cheaper

Faced with new time and cost pressures, NDI system suppliers are integrating inspection with manufacturing to reduce its share in part cost and cycle time.

-

Formula 1 team optimizes car design-to-build process

FEA-to-CAD translation tool opens doors to cross-department communication and frees up time for R&D and test-piece manufacture.

-

Revisioning the Viper: Clamshell hood challenge

Autoclave-cured carbon-fiber prepreg hood/fender combo proves as technically formidable as it is visually stunning.

-

Cutting the cost of integrated composite aerostructures

A unitized all-composite aircraft door concept is realized in one shot with no fasteners.

-

SAMPE 2013 Long Beach new product showcase

The SAMPE 2013 trade show (May 6-9, in Long Beach, Calif.) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.

-

Chevy Volt battery pack: Rugged but precise

GM and partners engineer composites for this complex assembly with an accent on repeatability.

-

Press-molding method emulates autoclave

Rubber tool insert avoids consolidation pressure “dead zones” and slashes cost.

-

Carbon is the choice for amphibious LSA floats

Superlight, landing-gear-equipped design gives light sport aircraft builders an option for land and water.

-

Virtual testing of composites: Beyond make & break

Software-based micromechanical modeling and analysis methods promise faster and more cost-effective aircraft development and testing programs.

-

Off-grid turbine: Helix in the wind

This new composite twist on the vertical-axis wind turbine makes no small impact on the private power market.

-

Tooling block makes affordable patterns for new superlight aircraft

Tooling for a new canard-winged pusher airplane, the e-Go (e-Go Airplanes of Cambridge, U.K.), was created from patterns made of EP678 epoxy tooling block, supplied by the Advanced Engineering Materials Product Group of Trelleborg Offshore UK (Skelmersdale, Lancashire, U.K.)

-

Integrated, optimized aircraft door

This composites manufacturer is betting its one-piece 3-D preform and RTM process will trim weight from today’s fastener-intensive “black aluminum” aircraft doors.

-

Forged composites replace complex metal parts

Powerhouse manufacturer’s high-pressure compression molding process forms prepregged CFRP components with forged-metal properties.

-

Redesigning for simplicity and economy

Military OEM makes the switch from sandwich construction to compression molding to optimize composite aerospace part.

-

Primary structure repair: The quest for quality

Composite airframes on commercial craft drive development of automated repair technology and industry-wide repair technician certification.

-

Self-deployable, composite satellite boom

Researchers design and validate a boom made of ultrathin carbon-fiber/epoxy laminate, using a novel, highly accurate analysis method.

-

PLM software streamlines robotic cell development

FASTCURVE and FASTTIP, part of FASTSUITE from CENIT (Stuttgart, Germany), have been used successfully by Hyde Group Holdings Ltd. (Cheshire, U.K.) to optimize composite wing manufacturing.

-

Tooling for composites: Evolutionary trajectory

New technologies and improved methods keep up as tools get bigger and more complex and toolmaking gets ever more challenging.

-

Reinforced thermoplastics in aircraft primary structure

Carbon/PEKK floor beams prove production worthiness of lower cost, fast coconsolidation process.

-

Learjet 85 composite pressurized cabin a cost cutter

Single-piece carbon fiber composite structure selected over multipiece aluminum fuselage barrel section in new bizjet design.

-

SPE's ACCE 2010 preview

Charting a composites course through the auto industry’s “perfect storm.”

-

Hotel wrap: Curvilinear pultrusions

Airport hotel’s striking wraparound roofline made possible, durable and affordable with pultruded flat panels and profiled support structures.

-

Integrated software: Streamlined hull & tool design

Although its reputation was solid, rigid inflatable boat (RIB) builder Planatech (Athens, Greece) recently sought ways to design new composite products and their corresponding tool sets faster, without compromising quality.

-

Very Light Jets Creating A Demand For Composites

"Baby" jets are causing an aviation buzz but will the market exist?

-

Modular composites: A perfect fit in new medevac helicopter

Bell Helicopter's new manufacturing parardigm replaces sheet metal with composites in a modular "snap fit" design.

-

JEC COMPOSITES 2009 Product Showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

Automating wind blade manufacture

Recent technology announcements portend a new era of more efficient blade production.

-

Windpower 2009 highlights

The show confirmed wind energy’s status as a recession-proof market for composites, but blade manufacturers were put on notice about the need to automate.

-

Team-built bus body bests all

OEM meets tight development schedule on superlight multipart molded shell to offset propulsion system weight in fuel cell-powered transit bus.

-

Pultruding cost out of aerospace parts

Design-for-manufacturing effort proves to be cost-effective for carbon/epoxy airfoil on expendable UAV.

-

Low-cost methods realize high-concept Superbus

Multifunctional mass-transport vehicle concept takes shape via resin-infused carbon/epoxy and vacuum-formed glass-reinforced thermoplastic sandwich construction.

-

Composites the right choice for subsea ocean observatory

Pultruded structure provides durable platform for Deep-ocean Environmental Long-term Observatory System (DELOS) project’s groundbreaking marine study.

-

Formula 1 team accelerates design-to-track speed

Race car builder automates manual chassis design phase with unique FEA-to-CAD utility.

-

Engineering Insights: Glass/Thermoplastic Hood Steps Toward Commercialization

The hood design for Hyundai’s QarmaQ concept car is evaluated against European and Japanese pedestrian safety requirements.

-

Engineering Insights: Composites Lessen Load in Fuel-Cell Demonstrator

CFRP decklid helps offset fuel-cell system weight to meet vehicle weight target.

-

Managing multi-axis manufacturing

Much early computer numerically controlled (CNC) machinery served short-run military and space programs where cost per part was too high to be acceptable in the manufacture of commercial aircraft. Now, Automated CNC machinery moves toward volume production and part-specific design.

-

FEA Roundup: Design, Simulation And Analysis Converge

New modeling and analysis software products increase the accessibility and reliability of finite element analysis data.

-

The ABCs of FEA

Computerized and adapted for composites, finite element analysis reduces R&D expense and shortens time to market.

-

Thermoplastic composites gain leading edge on the A380

Breakthrough manufacturing process produces lightweight, affordable glass-reinforced PPS J-nose on the worlds largest commercial aircraft wing.

-

Very Light Jets Creating A Demand For Composites

"Baby" jets are causing an aviation buzz but will the market exist?

-

Why Microstructure Matters

Microtesting composite materials speeds seleMicrotesting composite materials speeds selection, allowing designers to consider more possibilities.ction, allowing designers to consider more possibilities.

-

SAMPE 2005 Product Showcase

SAMPE's U.S. Symposium and Exhibition highlights technological innovation and market expansion.

-

Nacelle manufacturers optimize hand layup and consider closed molding methods

Focused on optimizing traditional hand layup, nacelle and thrust reverser manufacturers cast an eye on future use of automation and closed molding.

-

Composite rib structure for Airbus A380 vertical tail

Fabricator exceeds Airbus performance requirements with hand layed rib truss structure for A380.

-

Fiber Placement The Centerpiece Of NCAM

Cryogenic composites just one facet of Lockheed Martins National Center for Advanced Manufacturing.