Purdue University composites center opens large-scale additive lab, seeks consortium partners

Purdue’s Composites Manufacturing and Simulation Center (CMSC) cut the ribbon on the Thermwood LSAM Research Lab, which partners can access with Purdue’s ADDITIVE3D simulation module.

On Oct. 28, Purdue University’s (West Lafayette, Ind., U.S.) Composites Manufacturing and Simulation Center (CMSC) hosted a ribbon cutting event for its Thermwood LSAM Research Laboratory at Purdue University, and announced its Composites Additive Manufacturing & Simulation (CAMS) Consortium.

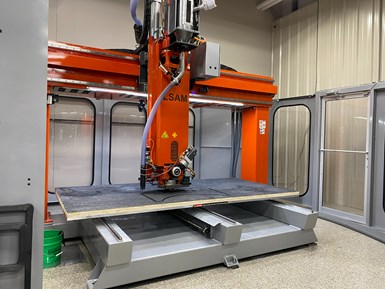

Located inside the CMSC at the Indiana Manufacturing Institute, the Thermwood LSAM Research Laboratory houses a LSAM 105 large-format, extrusion-based 3D printer and five-axis LSAM Additive Trimmer. According to Thermwood, the two-step system is capable of printing and trimming parts up to 5 x 10 x 4 feet at print rates up to 200 pounds per hour. The system has been modified to enable print temperatures over the typical 450°C, Thermwood says, for experimentation and research purposes.

R. Byron Pipes, executive director of the CMSC of Purdue University, said during the event that the initial focus for the laboratory will be composite tooling.

Ken Susnjara, chairman and CEO of Thermwood Corp. (Dale, Ind., U.S.), noted, “Our goal is to take this technology to new levels, and expand into mainstream markets.”

The CAMS Consortium aims to provide its paid members with access to Additive3D, a physics-based simulation workflow developed by Purdue in conjunction with Dassault Systèmes (Vélizy-Villacoublay, France) software; printing studies using the new laboratory’s LSAM 105 printer or CAMRI, a smaller-scale printer built by Purdue for R&D work; educational materials and training; and technical support from Purdue.

Five-axis LSAM trimmer at the Thermwood LSAM Research Laboratory. Photo Credit: CW

Eduardo Barocio, assistant director of additive manufacturing (AM) at the CMSC, explained during the event that Additive3D system is a simulation workflow that works in conjunction with Dassault software and extrusion deposition additive manufacturing (EDAM) to streamline and digitize the design and printing process for discontinuous fiber composites. Material and machine characteristics and properties are input into the software, and Dassault CATIA and SIMULIA are used to simulate part characteristics like geometry, stress and deformation; process parameters like heat transfer and temperature; and part performance.

Barocio noted that future iterations of Additive3D will expand to other AM processes and material types, including continuous fiber.

These announcements were part of Purdue’s Large-Scale Additive Manufacturing Celebration, which also celebrated the one-year anniversary of the opening of the 3DEXPERIENCE Lab and Education Center of Excellence with partner Dassault Systèmes. The celebration included speakers from Purdue University, Dassault Systèmes, Boeing and Thermwood, and focused on innovations in digital twins and simulation, and these partnerships aiming to propel the technology forward. Purdue’s research in these fields also goes beyond 3D printing. Speakers and researchers at the event spoke about additional digital twin and simulation projects such as Form3D, a project in partnership with Boeing for simulation-based carbon fiber/thermoplastic composite sheet forming, as well as multi-scale modeling of resin transfer molding (RTM), infusion and other processes.

Related Content

CIRA qualifies CMC structures for the reusable Space Rider

Italian team designs, builds and tests multiple large, complex thermal protection system structures made from patented ISiComp C/C-SiC ceramic matrix composites.

Read MoreRocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

Read MorePartners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.

Read MoreNCC receives investment to support next-gen composite wing

The NCC was awarded a £15.8 million U.K. government grant for HRMCap to de-risk, accelerate innovation in high-rate large aerocomposites structure manufacturing.

Read MoreRead Next

Purdue University to establish Thermwood LSAM research laboratory

Industry-funded research to pursue large-scale composite thermoplastic additive manufacturing, with the goal of providing services to enhance, encourage and expand the adoption of large-scale AM for diverse industrial applications.

Read MoreRobotic computed laminography brings X-ray CT resolution to large composite structures

Omni NDE collaborative robots, X-ray end effectors and Voxray’s reconstruction approach enables 5-micron inspection of aerospace parts without size constraints.

Read MoreCutting engine weight via thermoplastic composite guide vanes

Greene Tweed replaces metal stator vanes with its DLF material co-molded with a metal leading edge that meets performance, cost and high-rate production targets while cutting 4 kg per engine.

Read More

.jpg;width=70;height=70;mode=crop)