WoundSIM software tool simplifies design and simulation of composite pressure vessels

Rapid and efficient tank design process is achieved via an integrated FEA software translator, advanced parametric optimization, simulation and load case testing and post-processing capabilities.

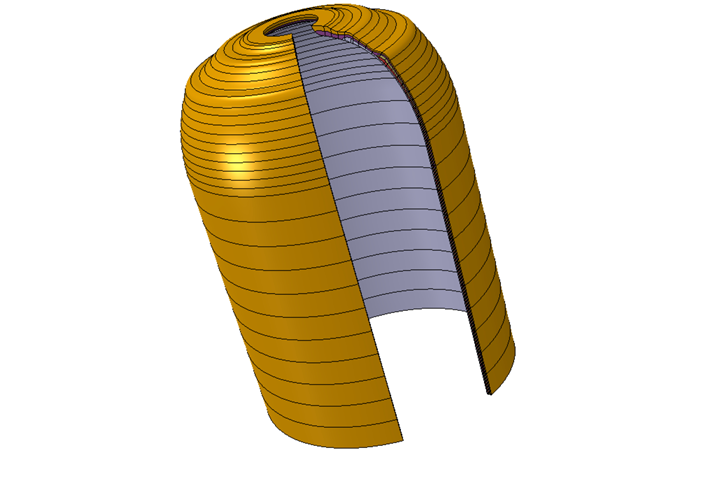

COPV tank model. Photo Credit, all images: S Vertical, QustomApps

WoundSIM is a new software tool targeting the design, simulation and optimization of composite-overwrapped pressure vessels (COPVs). While it is primarily used in the automotive and aerospace industries, it has gained usage with the U.S. Navy, various research centers, the education sector and for hydrogen storage as a rapid and efficient tank design process. It is developed, supported and maintained by Dassault Systèmes (Vélizy-Villacoublay, France) Simulia development partners QustomApps (Ponder, Texas, U.S.) and S Vertical (Châtenay-Malabry, France). The first beta version was released in 2019, with additional features to be included in 2022.

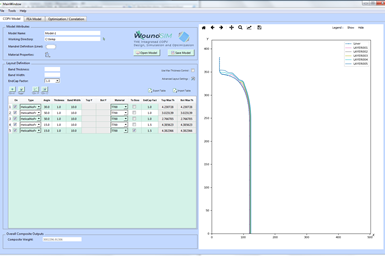

Under WoundSIM, a graphical interface is used to instantaneously view the composite layup as the table of composite layers is defined. Layer thickness buildup is automatically calculated, along with the varying wind angles. Smeared material properties are also computed and assigned throughout the COPV, and an integrated finite element analysis (FEA) software translator enables users to generate a run-ready FEA model to assess the thermal and mechanical responses of the COPV.

Principle WoundSIM features noted include:

- Enhanced layer thickness buildup for better correlation against geometry of produced tanks;

- Comprehensive design parameters enabling a quick variation of layer shape;

- A comprehensive, standalone user interface;

- GUI short time response (<1 sec/30 layers);

- Smart layup rendering for easy layer selection and identification;

- Rapid, fully automated tank FE model generation and post-processing;

- Full compatibility with Dassault Systèmes’ Simulia Abaqus Unified FEA;

- Automated Abaqus WCM models conversion;

- Compatibility with Simulia Isight for advanced parametric optimization;

- Public XML API to ensure compatibility with other winding software or customer’s in-house tools and formulations;

- Integrated tank parametric optimization capabilities to reduce tank weight;

- And integrated models VS tests calibration.

After the layup definition and visualization in the WoundSIM interface, users can generate the reservoir geometry and the corresponding FEA models in order to perform all needed simulations. Generated models include tank layer geometry and enhanced reservoir mesh generation; transformed material properties; automated assembly with other reservoir components; loads and boundary condition definitions; and the possibility to generate 2D, 3D, shell and solid models. Abaqus/CAE models can also be edited and enriched by the user.

WoundSIM graphical user interface (GUI).

All required load cases to design the tank can be run on the generated FE models, including static/dynamic burst pressure, heat transfer analysis, coupled temperature displacement, dynamic drop tests and impacts and cyclic and fatigue assessment. Fail stress and fail strain parameters can also be included in the FE analysis for a realistic prediction of composites layers failure.

Moreover, the WoundSIM-to-Abaqus interface provides a number of seamless post-processing capabilities such as specialized path plotting and contour plotting tools for quick tank response assessment. WoundSIM includes a compiled user subroutine library that gives access to all composite-specific output post-processing quantities such us winding angles, fiber matrix stresses and strains and damage parameters.

Finally, WoundSIM offers advanced engineering capabilities and integrated algorithms that allow several capabilities for composite reservoir designers and simulation engineers. Some capabilities involve parametric design, Design of Experiment, batch computing, reservoir geometry variability study, correlation to other winding software, models correlation with produced reservoirs and reservoirs images processing.

View this link for more information on WoundSIM.

Related Content

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreMulti-material steel/composite leaf spring targets lightweight, high-volume applications

Rassini International was challenged by Ford Motor Co. to take weight out of the F-150 pickup truck. Rassini responded with a multi-material steel/composite hybrid leaf spring system that can be manufactured at high volumes.

Read MoreCFRTP enables better, greener smartphones

Carbon Mobile’s “monocoque” design eliminates separate case, cover and frame, better protects electronics and simplifies disassembly.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More