Sensors

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Ginger Gardiner

Senior Technical Editor, CompositesWorld

Plastic injection to composite overmolding: Evolving mold design for lightweight manufacturing

Hybrid molding is increasing for faster, high-volume production of more integrated parts, but success requires process knowledge which includes new mold developments as processes converge.

Read MoreSmartbeam develops HMS-embedded composite profiles for space

Project goals adapted filament winding to properly integrate optical and carbon fiber sensors and meet technical requirements, resulting in a verified, simplified process for smart composite structures at reduced cost.

Read MoreContactless sensors enable smart composites production

CAMX 2025: Attendees can experience both of sensXPERT’s FlexCure and Insight sensor products, both achieving reduced waste, shorter cycle times and more actionable insights into resin curing.

Read MoreSensory consolidation roller for laser-based AFP enables innovative temperature measurement

Within the InSiTe project, IFW has demonstrated embedded fiber optic sensors for continuous measurement of temperature in the area of compaction with high spatial resolution up to 0.65 millimeter.

Read MoreJetZero announces Collins Aerospace nacelles, new campus and use of fiber optic sensors

California startup continues push toward first flight of its blended wing body (BWB) demonstrator aircraft in 2027, which uses carbon fiber composite fuselage, wings.

Read MoreIMT Nord Europe launches COMPOLIS initiative

COMPOLIS is an R&I hub bringing together industrial partners, dedicated to connected materials and structures with the ultimate goal of digitalizing composite materials.

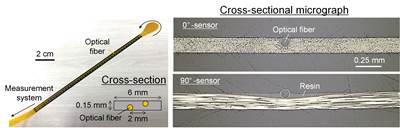

Read MoreMeasuring ply-wise deformation during consolidation using embedded sensors

Strip-type shape sensor method claims real-time measurement of ply-wise deformation.

SensXPERT introduces HF-DEA contactless quality control for composites

High-frequency dielectric analysis (HF-DEA) is a portable, standalone device that enables accurate measurements through composite layers up to 40 millimeters thick.

Read MorePLEIADES project targets automated induction welding, vitrimeric formulations and digital supply chain

EU-founded project is supporting composite technology advancement for aerospace via automated manufacturing, integrated sensing, novel composite materials development and digital transformation.

Read MoreMORPHO advances structural prognostics, health monitoring and composites manufacturing efficiencies

EU project concluded in January 2025, delivering on its goals to enhance aerospace industry performance and sustainability through real-time monitoring, intelligent control systems and innovative recycling techniques.

Read MoreMiniLab consortium produces first full-scale thermoplastic composite hydrofoils

Project advances toward first recyclable foils for ocean racing, part of “Infinite Foil” finalist for JEC Innovation Award 2025.

Read MoreMoistTech Corp. introduces IR3000 moisture sensors

Near infrared (NIR) sensors deliver precision moisture control and reliable moisture analysis for natural fibers, synthetic fibers and blended fabrics.

Read MoreThe evolution, transformation of DEA from lab measurements to industrial optimization

Over the years, dielectric analysis (DEA) has evolved from a lab measurement technique to a technology that improves efficiency and quality in composites production on the shop floor.

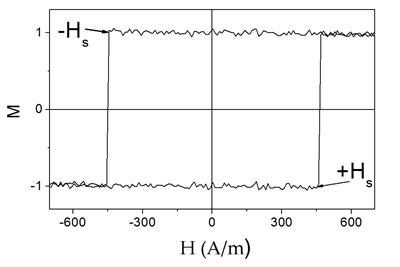

Read MoreGlass-coated magnetic microwires for nondestructive composites monitoring

Glass-coated, amorphous microwires combine nanometer to micrometer diameters, enabling embedding into composites without degrading mechanical properties.

VIDEO: AI, cameras and lasers for FOD detection

Virtek Vision demonstrates its Iris AI technology at CAMX 2024. It combines laser projection with machine learning software to detect foreign object debris during a composite layup.

Read MoreStreamlining aerospace composites operations with RFID tracking

Tier 1 Sekisui Aerospace’s implementation of RFID tracking, sensors and Xemelgo software at two of its production facilities led to increased productivity, eliminating bottlenecks and reducing labor costs.

Read MoreTPI, University of Texas participate in wind blade cure optimization project

Physics-informed machine learning algorithms will be applied to simulate and optimize composite wind blade curing in an effort to advance smart composites manufacturing in industry.

Read MoreRVmagnetics introduces R&D service for MicroWire technology

RVmagnetics now enables the development of composite measurement and monitoring systems based on its passive sensor technology, to fit exact customer requirements.

Read MoreTechnology Marketing Inc. to distribute VacPuc digital sensors

VacPuc is expanding its range of global distributors to deliver its vacuum pressure measurement solution to the composites market.

Read MoreGill highlights custom sensors expertise with industry flexibility

Product offering encompasses specialist level sensing, condition monitoring, position sensors and engine control products for composites-based applications.

Read MoreTwenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

Ginger Gardiner

Senior Technical Editor, CompositesWorld

Measuring energy use to enable sustainable composites production

Airbus subsidiary CTC uses new technology to measure energy use in machine components and processes to optimize equipment, production lines and guide decisions for future composites.

Read MoreU.K. academics head up flat fiber sensor research for composites

Six universities are in charge of developing flat fiber sensors, which will then be applied with industry partners, to determine their impact in monitoring composites manufacturing and more.

Read MoreNext-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Read MoreHBK enhances sensor offerings with MicroStrain acquisition

MicroStrain designs and manufactures high-precision inertial and wireless sensing systems that cater to industries such as automation, mobility and unmanned vehicles.

Read MoreUniversity of Southampton develops miniaturized optical fiber condition monitoring technology

A more compact, affordable strain interrogator, currently developed for FBG monitoring, may enable more widespread adoption of optical fiber sensing used in composite materials.

Read MoreTemperChip machining temperature sensor for composites

Patented device provides real-time machining data to monitor and accurately predict tool life, opening up the horizons to measure a variety of parameters between cutting tool and material.

Read More