Compression Molding of Composites

Compression molding is a widely employed technique in composite manufacturing, involving the use of heat and pressure to shape composite materials. In this process, a pre-measured amount of composite material, often in the form of sheets or pellets, is placed into a mold cavity. The mold is then closed and subjected to high pressure and temperature, allowing the material to conform to the shape of the mold. As the material compresses and solidifies, it forms the desired product. Compression molding is favored for its ability to produce complex shapes with high fiber volume fractions, ensuring strong and consistent composite parts.

Latest Compression Molding Articles

VIEW ALLKraussMaffei presents automotive-focused BrightStar electric press

Fully electric press offers precise temperature control and fast mold change for press lamination, edge folding applications and even ultrasonic welding of TPC.

Read MoreCFRP boosts power, drops weight for next-gen fire truck pumps

Carbon fiber enables KASE Pumping Systems to eliminate corrosion and increase durability, including a high-capacity 6,500-gpm, ultra-compact 200-pound pump that aids emergency services.

WatchPost Cure: NFPA-rated carbon fiber composite fire truck pump for firefighting, energy industries

Direct engine-driven systems or firetruck applications benefit from the lightweight, compact, high-volume centrifugal pump by KASE Pumping Systems.

Read MoreLIFT to lead new "Critical Materials Processing" program on ceramics, CMC

Multifaceted project aims to accelerate development and scale-up of ultra-high temperature material technologies including ceramic matrix composites (CMC) and carbon fiber as a precursor in CMC preforms.

Read MoreSABIC composite hybrid battery cover enhances EV safety, efficiency

SABIC collaborated with Engel, Siebenwurst, Forward Engineering, Ensinger and Envalior to develop a thermoplastic composite EV battery cover, combining strong structural performance, flame retardancy and design efficiency.

Read MoreWabash introduces larger custom presses up to 2,500 tons

Larger presses with platen sizes up to 10 × 10 feet and 1800°F operating temps service increasing component size, complexity and material diversity in composites manufacturing.

Read MoreKnowledge Centers

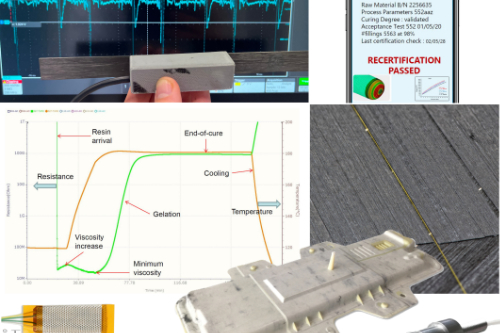

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORELatest Compression Molding News And Updates

Greene Tweed to deliver advanced TPC components for jet engines

More than 50 custom-designed parts made from Greene Tweed’s Xycomp DLF thermoplastic composite material will be delivered over the course of this 10-year strategic agreement.

Read MoreCRG Defense secures $2 million contract to build hybrid military vehicle electric motors/generators

The effort also supports a broader initiative to accelerate hybrid-electric propulsion technologies to ground and air platforms, leveraging FRP structures and composite-based magnetic retention systems.

Read MoreCustom-built composites technologies align material, geometry and manufacturing strategies

CAMX 2025: Persico Group is a technology partner providing a variety of processing platforms catering to everything from prototyping to full-scale production.

Read MorePorsche develops TABASKO method for lightweight vehicle series production

Patented carbon fiber-reinforced polypropylene tape-based process supports cost reduction, light weight and thinner walls without sacrificing rigidity.

Read MoreWickert press advances Chemnitz polymers, composites and metals research

Since its installation, the rapid heating/cooling press has become of great importance to the Institute for Lightweight Structures’ work in processing high-performance structural and hybrid components for industrial-scale applications.

Read MorePinette commissions large-scale stamp-forming press for TPCs

Airbus Aerostructures facilities will integrate this forming press that is expected to advance next-gen aerospace parts production thanks to its size and performance.

Read MoreFeatured Posts

Troubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

Read MorePrepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

WatchComposite bipolar plates provide 81% improvement to hydrogen fuel cell power density

Ultra-thin CFRTP plates developed by Hycco achieve a 7.5 kilowatt/kilogram power density, high durability for fuel cells in long-flight drone and heavy-mobility applications.

Read MoreSRI develops scalable, infiltration-free ceramic matrix composites

Work in two DOE projects is demonstrating C/C-SiC produced in 3-5 days with <5% shrinkage, <10% porosity and 50% the cost of conventional C/C and C/C-SiC.

Read MorePUR composite sandwich panels for 3D automotive parts, high-volume panels and more

At its U.S. sites, Ascorium produces glass fiber/PUR 3D parts via semi-automated molding, high-volume flat panels via a continuous line while working toward bio-based PUR and recycling.

WatchVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Watch