Thermoplastics

Thermoplastics play a pivotal role in composite materials by serving as the matrix phase that binds reinforcements together. Unlike thermoset resins, thermoplastics possess the ability to soften and reform when heated, allowing for reshaping and recycling. They offer unique advantages such as high toughness, chemical resistance, and easy processing, making them versatile in various industries like aerospace, automotive, and consumer goods. Composites using thermoplastic matrices exhibit exceptional damage tolerance and are sought after for their potential in complex manufacturing processes like injection molding, enabling efficient production of intricate and high-performance parts.

Latest Thermoplastics Articles

VIEW ALLFIDAMC hosts Aerospace Thermoplastics International Summit in Madrid

Leading representatives from aerospace industry, public institutions, technology centers and universities discussed the challenges and opportunities that will shape future airframes.

Read MoreXenia launches Xecarb PA12-CF-ST 3D printing filament

Carbon fiber-reinforced PA12 material delivers reliable performance and precision for functional 3D printed components.

Read MoreThermoplastic composite fabrication: Thermal processing

Establish a proper thermal cycle during TPC rapid forming and achieve reproducible, successful parts through key material selection and process method understanding.

Read MoreEnvalior plastics, composites expertise earns two SPE Automotive Awards

Envalior was recognized with the Grand Innovation Award and first place in Enabler Technology for a roof cap design and hybrid composite battery cover, respectively.

Read MoreAZL Joint Partner Project to build holistic approach for TPC-driven pressure vessel design

Design, manufacturing processes and material configurations will be sought through three work packages over a 9-month period through the combined efforts of participating engineers and decision-makers.

Read MoreFibreCoat, Lofith Composites form partnership to test ultra-resilient TPC materials in space

TPC satellite panels made from FibreCoat’s energy-saving coated fibers and Lofith’s low-water impregnation process will spend around 12 months in space starting in 2026 to test their performance.

Read MoreKnowledge Centers

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORE

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORELatest Thermoplastics News And Updates

Four Syensqo innovations are recognized at 2025 SPE Automotive Awards

Syensqo’s fiber-reinforced polymers, specialty compounds and bio-based PPA materials earn automotive impact distinction.

Read MoreBelgium-Netherlands event brings together industry leader insight on TPC, FRP recycling

Save the date for this free cross-border, expert-driven event by Agoria, Sirris and Brightland Materials Center on Nov. 12 in Belgium.

Read MoreFiberglass-reinforced nylon PA12 is co-developed by AGY, Orion Compounding

Implementation of AGY’s S2 Glass fiber enhances the material’s tensile and impact strength, elongation at break, and improves tensile and flexural modulus.

Read MoreAvient, ReForm Composites accelerate TPC adoption in construction

ReForm’s pultrusion technology with Avient’s composite materials enables curved continuous fiber TPC profiles demonstrated in the PolyDowel infrastructure project.

Read MoreIRT Jules Verne, partners launch SCRATCH TPC assembly project

A continuation of SPECTRA, this project’s technological building blocks will contribute to the deployment of a matured conduction welding solution to improve aerospace-grade TPC assembly.

Read MoreAvient, FSJ Tactical advance ballistic-rated composite wall panels

Fiberglass-reinforced ThermoBallistic panels for facility protection applications are capable of encapsulating projectiles and preventing harmful deflection and ricochet.

Read MoreFeatured Posts

Improving hail impact resistance of discontinuous thermoplastic composite parts

Greene Tweed examines failure behavior, identifying key factors for improvement and demonstrating sufficient design for complex-shaped aeroengine components.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreTroubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

Read MoreParis Air Show highlights advanced materials, industry momentum

This year’s international air show offered a glimpse of the rapidly expanding future for composites in aerospace.

Read MoreComposites in India: A market forecast for 2025-2030

India is the world’s fastest-growing market for composites, with a comprehensive ecosystem pivoting toward self-sufficiency in production and 200% growth in its carbon fiber value chain.

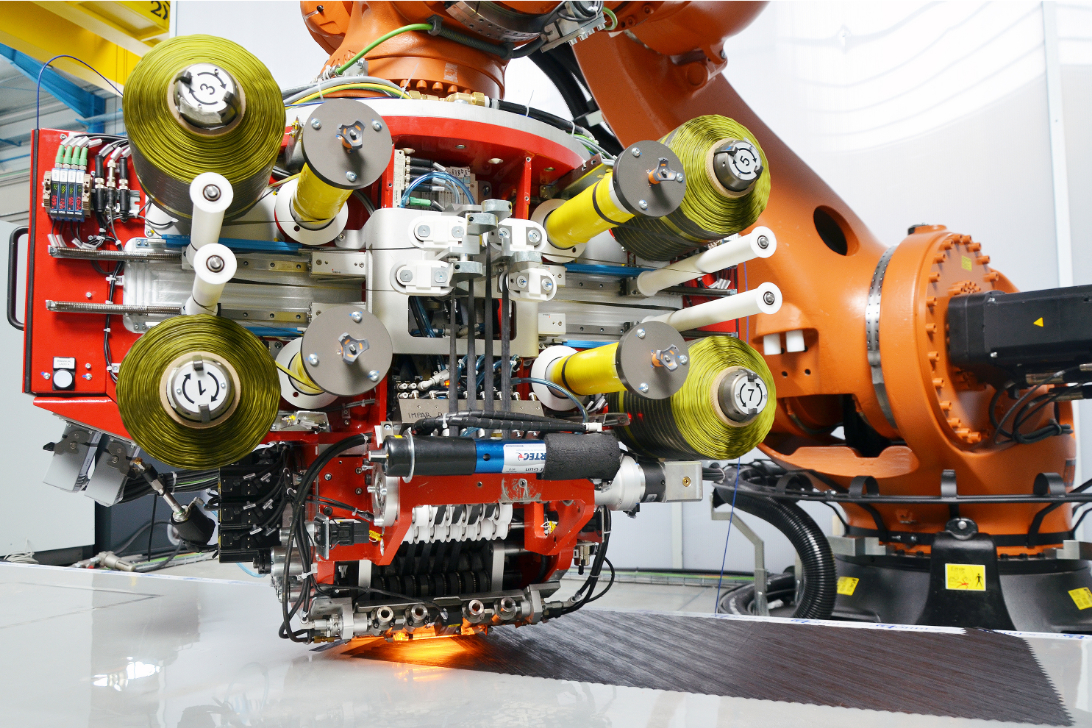

Read MorePost Cure: Bionic fiber placement produces load-optimized, nature-inspired thermoplastic composite preforms

Fibionic’s fibionic fiber placement (FPP) technology enables the development of “fiber skeletons,” semi-finished parts suitable for any application that incorporates composite reinforcement exactly where it is needed.

Read More