ESSENTIAL READING

VIEW ALLThermoplastic composite fabrication: Thermal processing

Establish a proper thermal cycle during TPC rapid forming and achieve reproducible, successful parts through key material selection and process method understanding.

Read MoreComposites end markets: Pressure vessels (2025)

H2 economy is set back by Trump policies, tariffs and funding pivot to defense and AI, but composite tanks remain a key segment with sales in CNG/RNG, growth in New Space and potential for H2-electric aviation.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreCW Tech Days — Upcoming and past events

CW Tech Days are virtual events dedicated to the topics impacting the composites industry today. Access past event recordings and register for upcoming Tech Days.

Read MoreTroubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

Read MoreComposites end markets: Automotive (2025)

Composites manufacturing intelligence drives circular economy solutions as automotive industry balances technical demands with sustainability mandates.

Read MoreKnowledge Centers

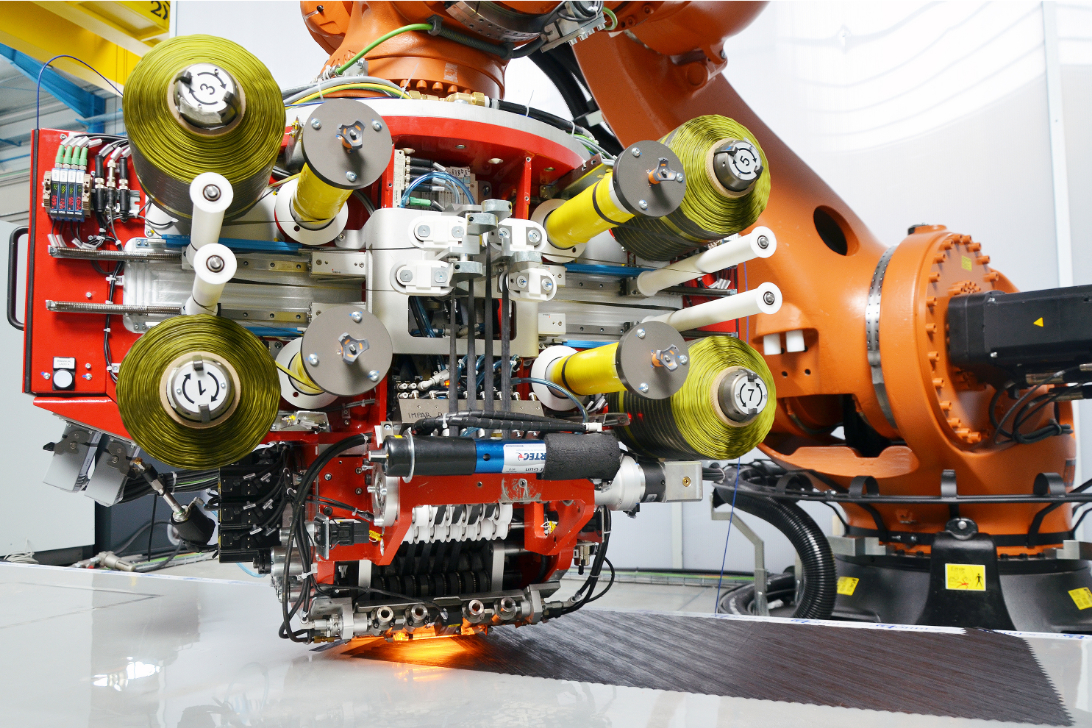

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORE

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORELatest National Composites Week News And Updates

DuPont extends Kevlar EXO aramid fiber to hard armor applications

Core components like helmets and plate inserts are Kevlar EXO’s main target, though it also has potential for aerospace, space and defense composite structures.

Read MoreMETOL circular TPC innovation wins ICS 2025 pitching competition

The startup, highlighting its fully recyclable thermoplastic polymer materials, achieved high scores across innovation, market need, feasibility, industry impact and pitch clarity.

Read MoreGKN Aerospace, Anduril UK sign partnership for U.K.'s future UAVs

Accelerated UAV and rotorcraft tech for U.K. defense programs will be supported through composite aerostructures, EWIS design and integration, a ground-based demonstrator, flight testing and Archer Aviation’s eVTOL expertise.

Read MoreFiberglass-reinforced, injection molded powertrain component wins 2025 SPE Innovation Award

Envalior, General Motors and Schaeffler are recognized for a novel thin-wall actuator gear design enabling electronic throttle control with 30% weight reduction, packaging efficiency and other enhancements.

Read MoreDawn Aerospace visits Oklahoma to advance historic suborbital space partnership

Through such partnerships, Oklahoma is making a broad statewide effort to grow a high-value aerospace and space economy via next-gen composite suborbital spaceflight initiatives.

Read MoreNCC to establish U.K.-based Large Structures Innovation Centre

National open-access innovation facility for large composite structures at industrial scale will be available to OEMs, Tier 1s and supply chain companies.

Read MoreFeatured Posts

November index slumps with multi-point losses

Significant declines in index components across the board lead to more than a season dip.

Read MoreFIDAMC TPC Summit: An interview with Aernnova Composites

Tier 1 aerospace fabricator discusses its work with thermoplastic composite (TPC) materials and how it is internally preparing for their application in future aircraft.

Read MorePlastic injection to composite overmolding: Evolving mold design for lightweight manufacturing

Hybrid molding is increasing for faster, high-volume production of more integrated parts, but success requires process knowledge which includes new mold developments as processes converge.

Read MoreTPC centrifugal compressor impeller effectively compress large volumes of hydrogen gas

Successful application of advanced thermoplastic composites (TPC) achieves impellers that reliably distribute, store and use undiluted H2 gas in transportation and industry.

Read MoreSourceBook 2026: Your ultimate guide to composites industry resources

Streamline sourcing with more than 1,900 suppliers, new breakout sections to help you navigate the latest industry trends and dynamic online resources.

Read MoreModular composites enable larger tanks for wastewater and biogas reactors

Toro Equipment uses biaxial fabrics, carbon fiber and Flex Molding for corrosion-resistant tanks that compete with steel, concrete and speed global installations.

WatchFAQ: National Composites Week

What is National Composites Week?

The goal of National Composites Week is to celebrate and bring attention to the myriad ways that composite materials and composites manufacturing contribute to the products and structures that shape the American manufacturing landscape today.

When is National Composites Week?

National Composites Week typically takes place in the month of August.

How do people and companies celebrate National Composites Week?

Individuals and companies alike can celebrate National Composites Week! One way to celebrate is to spread the word about how you or your company are involved with composites. This can be done through social media, events, newsletters, company emails and message boards, and press releases. Click here for ideas.