Space

Composites have been used in space since our early steps into the cosmos. Often turned to for their light weight and high strength, these materials have a history of use in spaceflight in such applications as payload fairings, satellite structures and heat shields. ► Explore the technologies, materials and strategies used by composites manufacturers working in the evolving space market at our virtual CW Tech Days: New Space Applications. Learn more and register here!

ESSENTIAL READING

VIEW ALLComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Introduction

High strength at low weight remain the winning combination that propels composite materials into new arenas, but other properties are equally important. This article outlines the case for composites and introduces SourceBook's overview of the materials and processes used to make them.

Read MoreKnowledge Centers

Review the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

LEARN MORE

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORELatest Space News And Updates

ILA Berlin 2026 focuses on competitiveness, technology and sovereignty

From June 10-14, ILA Berlin brings together international aerospace, defense and space industries, with several live stages and an extended Talent Hub.

Read MoreOrbex makes part setup 900% faster for key composite parts ahead of inaugural rocket launch

The introduction of MSP metrology products have ensured right-first-time machining for Orbex as it ramps up production of its carbon fiber Payload Avionic Module.

Read MoreFibreCoat, Lofith Composites form partnership to test ultra-resilient TPC materials in space

TPC satellite panels made from FibreCoat’s energy-saving coated fibers and Lofith’s low-water impregnation process will spend around 12 months in space starting in 2026 to test their performance.

Read MorePHOEBUS project makes progress on CFRP liquid oxygen, hydrogen upper stage tanks

The ESA project has proven that linerless CFRP tanks for Ariane 6 rocket can handle the extreme temperatures of liquid H2 and O2, and are moving on to testing campaign for 2-meter and 3.5-meter tanks in 2026.

WatchDLR rocket flight in ATHEAt program demonstrates CMC nose, movable body flaps

Successful flight tests heat-resistant components and innovative sensor technologies.

Read MoreDLR exhibits full-scale CFRP liquid hydrogen tank test item for zero-emission aviation

The German Aerospace Center Institute for Lightweight Systems exhibits 1.9-meter autoclave infusion composite structure as part of LUFO UpLift project aiming for LH2 as part of short-haul aircraft propulsion by 2040.

WatchFeatured Posts

National Composites Week 2025: Space

Commemorating the theme “Performance With Purpose,” CW has gathered key stories over the last year that exemplify how composites have progressed space exploration and satellite programs.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreRevolutionizing space composites: A new era of satellite materials

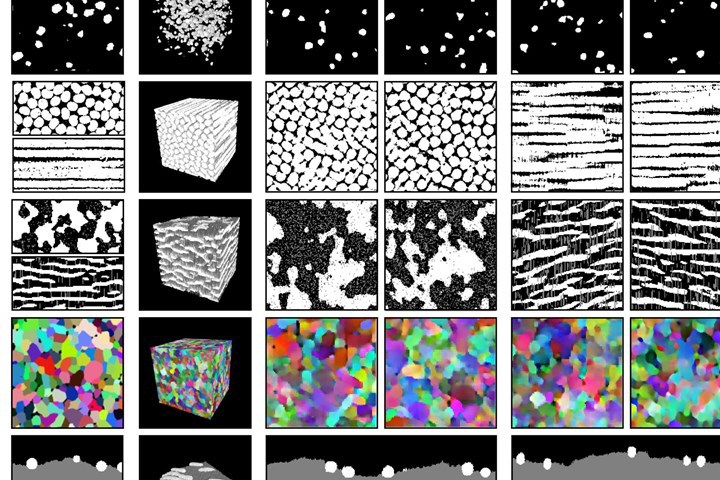

A new approach for high volumes of small satellite structures uses low-CTE, low-cost CFRP cellular core, robust single-ply skins and modular panel systems to cut lead time, labor and cost for reflectors, solar arrays and more.

Read MoreParis Air Show highlights advanced materials, industry momentum

This year’s international air show offered a glimpse of the rapidly expanding future for composites in aerospace.

Read MoreAutomating oxide CMC for higher part volumes

FOX Composites has adapted infusion and RTM for slurry-based matrices, commercializing its VASI and IFOX technologies for automatable, scalable, serial production of high-quality oxide ceramic matrix composite parts, already proven in flight missions and a pilot-scale line.

Read MoreOptimizing a CFRP landing leg demonstrator

MT Aerospace achieves design for manufacturing, integrating multiple elements into one-piece structure using AFP and 3D printed tooling to meet time and budget constraints.

Watch