Composite submersibles: Under pressure in deep, deep waters

Manned deepsea exploration calls for a highly engineered composites solution that saves weight and preserves life — at 6,500-psi service pressure.

Even as massive amounts of money, energy and attention are being paid to the development of privately funded launch and delivery systems for space exploration — and the application of composites therein — an environment much closer to home is, despite its proximity, as remote and difficult in its own way to access and study.

At an average depth of about 3,810m, with a maximum depth, at Challenger Deep in the Pacific, of 10,916m, the world’s oceans offer a formidable challenge to explorers. Scientists, marine biologists or oil and gas engineers and others who would dive to such depths require a vessel that can withstand deepsea water pressure that, at the deepest point (almost 11,000m), is a massive 16,000 psi or 1090 atmospheres.

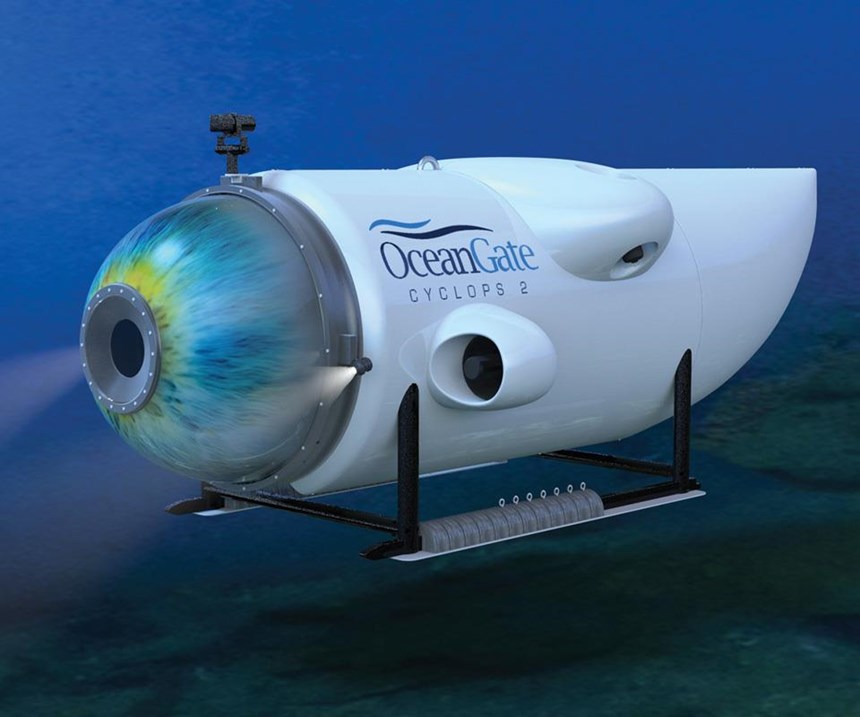

Such vessels, called submersibles, offer capacity for three to five occupants, can explore depths from 1,200m to 6,500m, provide a viewing porthole or portholes, and are equipped with lighting systems and cameras. Conventional submersibles feature steel, aluminum or titanium hulls. Metallic hulls, however, because they are not buoyant in designs for depths of more than 2,000m, present challenges when it comes to managing ballast for ascent and descent. In particular, metal-hulled craft require the use of syntactic foam attached to the outside of the craft to achieve neutral buoyancy.

In 2014, submersibles manufacturer OceanGate Inc. (Seattle, WA, US) was coming off the successful launch of Cyclops 1, its steel-hulled, five-person craft, rated for underwater exploration to a depth of 500m. The company was set to embark on development of Cyclops 2, a five-person research-class submersible, designed for a maximum depth of 4,000m.

OceanGate CEO Stockton Rush says the company had been evaluating the potential of using a carbon fiber composite hull since 2010, primarily because it permits creation of a pressure vessel that is naturally buoyant and, therefore, would enable OceanGate to forgo the use — and the significant expense — of syntactic foam on its exterior. So, for Cyclops 2 OceanGate decided to avoid the metallic hull altogether and began a search for a manufacturer that could help it develop a composite hull.

It is believed that the first time carbon fiber composites were applied to the hull of a deep-diving, manned submersible was for the one-person DeepFlight Challenger, commissioned by adventurist Steve Fossett in 2000 for a dive to the bottom of Challenger Deep (see Deepsea submersible incorporates composite pressure capsule). Designed and built by famed marine engineer and submersible designer Graham Hawkes, a principal at the time of Hawkes Ocean Technologies (Point Richmond, CA, US), it featured a cylindrical carbon fiber/epoxy composite hull with 6-inch-thick walls. It was nearing completion in 2007 when Fossett was killed in a light-aircraft crash. The Challenger was subsequently sold, and has yet to be fully tested or deployed in a deepsea dive. Spencer Composites Inc. (Sacramento, CA, US), a designer/manufacturer of composite parts and structures for a variety of end-markets, had designed and fabricated the DeepFlight Challenger’s hull.

“I knew of the submersible Graham Hawkes designed for Steve Fossett,” says OceanGate’s Rush. “And I knew Spencer Composites manufactured that cylinder.”

Spencer Composites’ president Brian Spencer signed a contract with OceanGate for the Cyclops 2 hull in early January 2017 and was presented with very basic — but challenging — performance parameters: Length, 2,540 mm; outside diameter, 1,676 mm; service pressure, 6,600 psi; pressure safety factor, 2.25. “They basically said, ‘This is the pressure we have to meet, this is the factor of safety, this is the basic envelope. Go design and build it,’” Spencer reports. And he was given six weeks in which to do it.

A room with a view

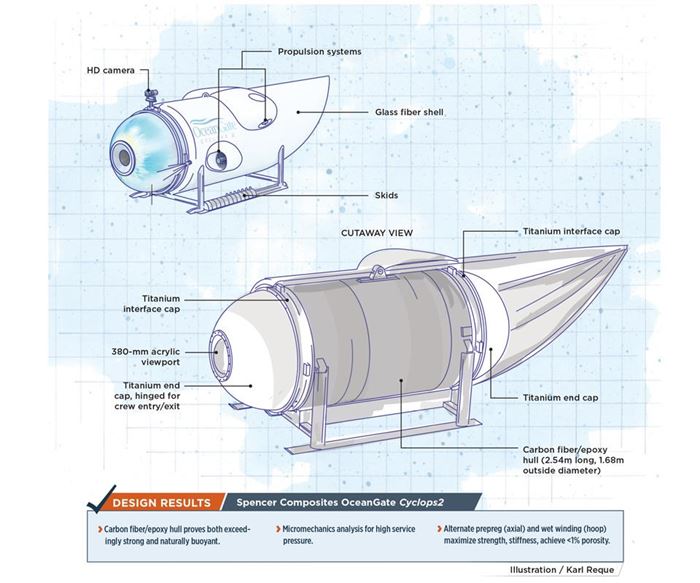

Cyclops 2 will consist of six primary structures:

- A cylindrical composite hull with room for five adults (a pilot and four passengers).

- Two titanium interface caps (one bonded to each open end of the hull).

- Two separate titanium hemispherical domes, the front one featuring an integrated 380-mm-diameter acrylic viewport.

- A glass fiber composite outer shell, bolted to flanges on the titanium interface caps.

- A landing skid structure, also attached to the interface caps.

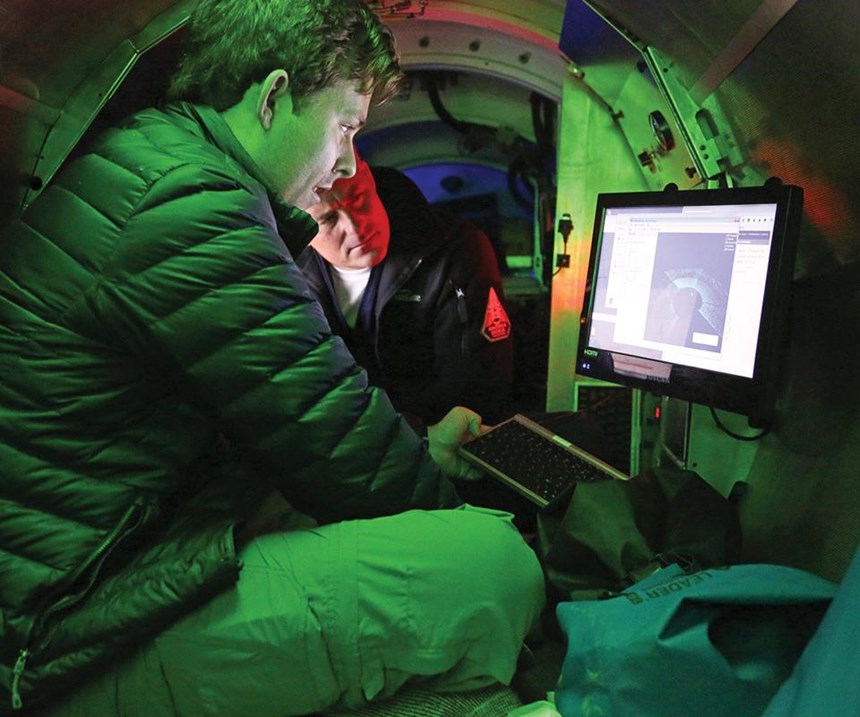

Nothing will be mechanically attached to, or penetrate, the composite hull other than the titanium caps. Deep-sea exploration — even in a well-designed, well-engineered, pressurized submersible — is not trivial and does carry with it substantial risk. The world record free-dive depth for a human is 214m (312 psi), and for most people the “safe” depth is probably half that. Thus, in the event of catastrophic failure of a submersible at any depth greater than even 250m, deepsea water pressure would instantly kill every passenger on board. And this is the primary concern of OceanGate and, by extension, Spencer Composites. Cyclops 2 faces potential failure in any one of three structures: the composite hull, the titanium end caps and the acrylic viewport. OceanGate designed a real-time health monitoring system that will acoustically monitor the composite hull to detect the pings and pops that signal to the pilot the risk of potential failure. Strain gauges will measure the health of the titanium end caps, which will see a maximum axial end dome load of up to 22 million lb. The viewport, says Rush, because it is acrylic, fails optically long before it fails structurally — and in this case, catastrophically — thus the crew will detect a problem visually first. In any case, the goal is to alert the pilot of potential catastrophic failure in time to enable movement of the craft to shallower, safer water.

Designing, building the perfect cylinder

The design of the Cyclops 2 hull, says Spencer, is based in large part on the strategy applied to Fossett’s DeepFlight Challenger. Thickness, he says, was estimated using micromechanics, and then verified with finite element analysis (FEA). Modeling was done in SolidWorks (Dassault Systèmes, Waltham, MA, US) and analysis was done with COSMOS/M, supplied by Dassault Systèmes subsidiary Structural Research and Analysis Corp. (Santa Monica, CA, US).

The biggest challenge, Spencer reports, was developing a manufacturable design that “would produce a consistent part with no wrinkles, voids or delaminations.” And without use of an autoclave. Spencer opted for a layup strategy that combines alternating placement of prepreg carbon fiber/epoxy unidirectional fabrics in the axial direction, with wet winding of carbon fiber/epoxy in the hoop direction, for a total of 480 plies. The carbon fiber is standard-modulus Grafil 37-800 (30K tow), supplied by Mitsubishi Chemical Carbon Fiber & Composites Inc. (Irvine, CA, US). Prepreg was supplied by Irvine-based Newport Composites, now part of Mitsubishi Chemical Carbon Fiber & Composites Inc. The wet-winding epoxy is Epon Resin 682 from Hexion Inc. (Columbus, OH, US). The curing agent is Lindride LS-81K frLindau Chemicals Inc.cals (Columbia, SC, US).

Initial design work indicated that the hull, to be rated for 4,000m depth with a 2.25 safety factor, should be 114 mm thick or 4.5 inches, which OceanGate opted to round up to 5 inches (127 mm) to build in an additional safety margin.

After layup and winding was complete, the cylinder was bagged with cellowrap and then cured in an oven at 137°C for 7 days. There was no postcure. Spencer says initial assessment of the cured cylinder shows that it has porosity of <1%. As CW went to press, the cylinder was being prepared for machining to cut it to length, square up the ends and bond it to the titanium end caps.

It will then be sent to OceanGate in Seattle to be instrumented before undergoing pressure testing. Assuming the hull passes muster, it will then become part of the first Cyclops 2 unit.

The finished Cyclops 2 will measure 6.7m long, 2.8m wide and 2.5m tall. It will weigh 8,600 kg and have payload capacity of more than 1,043 kg. Integrated into the outer shell of Cyclops 2 will be four electric thrusters for propulsion, buoyancy-control and navigation systems, four 20,000-lumen LED lights, HD cameras and other accessories. The crew will enter and exit Cyclops 2 through the front of the hull, which will be accessed via its hinged titanium end dome.

OceanGate’s Rush says Cyclops 2 will offer a nominal descent/ascent rate of 50m/min. Its standard life support systems can accommodate an 8-hour dive, but emergency systems are designed to provide an additional 96 hours of life support. The service limits of Cyclops 2, therefore, says Rush — water depth not withstanding — “are bladder, food and attention span.”

Notably, its 380-mm acrylic viewport, says Rush, is twice the size of any viewport on a competing submersible and should offer passengers unprecedented views of the waterscape.

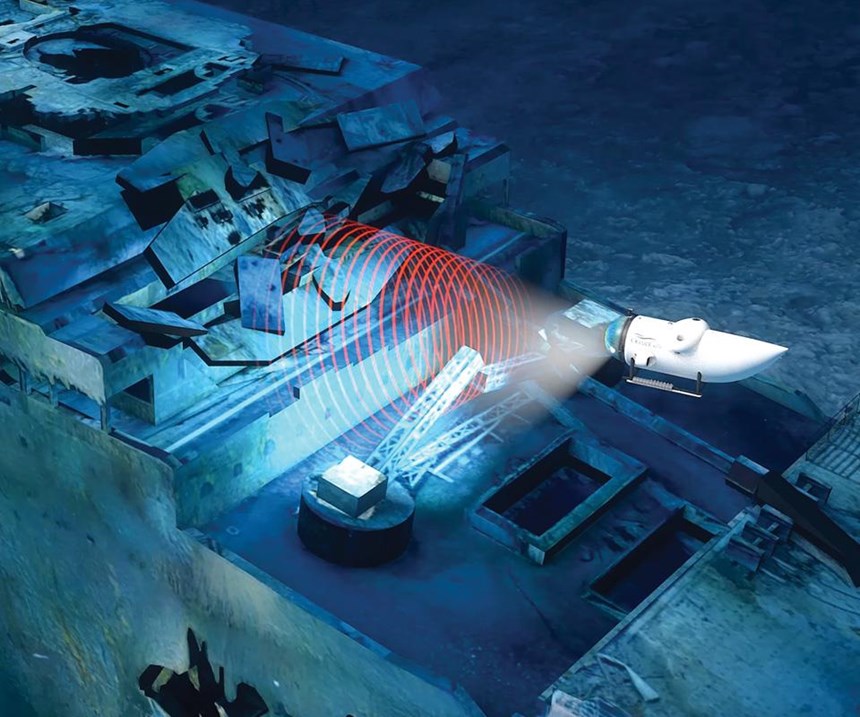

Cyclops 2 will enter the water for the first time in November of this year, followed by a deep-dive test in early 2018. If that goes well, its first mission, in May 2018 in the North Atlantic, will be a descent to the wreckage of the Titanic, which sits 3,688m under the surface. The goal? Capture high-definition still and video images of the Titanic, and gather sonar and laser measurements of the ship and the ship’s debris.

After the Titanic mission, Cyclops 2 will be off on a variety of other missions that, says Rush, will keep the craft busy for the rest of 2018. OceanGate, he says, will build at least four Cyclops 2 submersibles, and as many as 20, depending on demand. Rush says Cyclops 3, 4 and 5 are already on the drawing board, will target depths of 6,000m and likely will feature carbon fiber composite hulls.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreNanopoxy, Nione jointly develop nanostructured epoxy resin

Epoxies featuring nanometric niobium pentoxide particles promote toughness, UV radiation resistance and other performance gains.

Read MoreComposite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More