NDT

Flexible, automatic NDT platform for manufacturing composites

IRT Jules Verne, working with Airbus, Daher and French consortium developed a mobile robotic inspection platform that uses less space, water

Ginger Gardiner

Senior Technical Editor, CompositesWorld

Voidsy expands composites NDT&E into international markets, grows business capabilities

In efforts to transform into a stable, internationally recognized company for quality assurance and predictive maintenance, voidsy is looking for distribution and partnership opportunities outside the DACH region.

Read MoreCycle Inspect announces carbon fiber NDT certification program purpose-built for cycling industry

Full certification targets bicycle MRO professionals, offering comprehensive composite material theory, UT and inspection training that aligns with ASNT standards.

Read MoreHexagon Digital Wave provides requalification services for oilfield service company’s gas transportation fleet

Noninvasive modal acoustic emission (MAE) technology will support composite cylinder inspection for the U.S. company’s virtual pipeline trailers through 2027.

Read MoreAI inspection system with laser projection advances layup precision

CAMX 2025: Visit Virtek to learn more about the Iris Ai system with its new Results Projection feature in action, closing the loop between detection and resolution on the production floor.

Read MoreShearography equipment well suited to composites NDT

CAMX 2025: Laser Technology Inc. features analysis tools like the LTI-2100 and LTI 5200, which are optimal for detecting subsurface composite flaws.

Read MoreCobot enables CAD-free materials inspection path planning

CAMX 2025: Rooted in simplifying complexity, LoneStar NDE Innovations’ Orion inspection tool is made to be rapidly deployable and intuitive, overcoming traditional inspection processes.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Hannah Mason

Technical Editor, CompositesWorld

Instron launches AVE3 noncontact video extensometer

Leveraging CDAT airflow technology and dynamic lighting, the AVE3 delivers a virtually noise-free strain signal, guarding against typical air disturbances when measuring materials in the lab.

Read MoreCactuX in-situ BOX simulates real-life conditions of composite samples during CT analysis

The autonomous in-situ BOX combines the environment temperature control function and power supply function, enabling new possibilities for material and internal structure research.

Read MoreAIMM Center for advanced composites NDT opens in Ogden, Utah

Attendees from SpaceX, Northrop Grumman, Hill AFB, 47G and others joined CICNDT and Omni NDE to demonstrate the latest in robotic CT, RT, shearography, thermography, laser UT and metrology.

Read MoreUTComp NDT inspection prepares FRP Class 40 racing sailboat

Ahead of the competitive Globe40 competition in September, UTComp’s ultrasonic capabilities were used to test the viability of the craft’s carbon fiber mast, boom and bowsprit on the water.

Read MoreFANTOM project forms basis for automated aerocomposite NDT

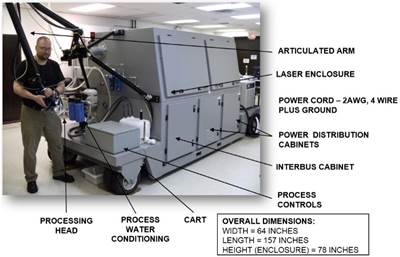

Three-year collaboration between IRT Jules Verne and partners achieves roboticized platform that meets efficiency and flexibility challenges of large composite parts inspection.

Read MoreRuckus Composites, Aerospace grows in-house composites machining, measurement and inspection

Recent in-house technology investments set Ruckus up to meet advanced composite inspection and precision machining demand.

Read MoreTwenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

Ginger Gardiner

Senior Technical Editor, CompositesWorld

Adaptix presents NDT3D inspection tool, targets aerospace

Mobile, low-power 3D imaging technology detects typical failure modes in complex composite structures with a high degree of fidelity.

Read MoreUTComp methodology enables nondestructive evaluation of phosphoric acid FRP piping system

Recent customer case study involved repeatable and scalable assessment of FRP composite pipes’ mechanical integrity via its UltraAnalytix NDT system.

Read MoreRadalytica advances multimodal 3D robotic scanner for composites, future aircraft inspection

Radalytica continues to develop its RadalyX nondestructive testing (NDT) system, merging diverse imaging methodologies for inspection in laboratories to aircraft hangars.

Read MoreVIDEO: AI, cameras and lasers for FOD detection

Virtek Vision demonstrates its Iris AI technology at CAMX 2024. It combines laser projection with machine learning software to detect foreign object debris during a composite layup.

Read MoreRobotic NDT inspection solutions, services enhance multitasking capabilities

CAMX 2024: Matec Instrument Companies Inc. presents its range of nondestructive ultrasonic testing technologies, including robotic inspection systems for increased efficiency and reduced physical strain.

Read MoreLaser NDT, DIC systems demonstrate optimized noncontact composites inspection

CAMX 2024: Dantec Dynamics is presenting three of its laser shearography NDT and DIC devices, geared toward reliable measurement results.

Read MoreLaser bondline inspection becomes reality

One of the Holy Grails of composites manufacturing has been reliable verification of adhesive bondline strength integrity. A technology that does just that has arrived.

Jeff Sloan

EVP, Content, CompositesWorld

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MorePhotothermal tomography system enhances composites NDT

JEC World 2024: Austria-based voidsy GmbH introduces the 3D V-ROX system, facilitating fast, contactless and nondestructive inspection with added efficiency and safety.

Read MoreXnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

Read MoreInnovation in ultrasonic inspection and nondestructive testing

With increasingly complex structural components working their way into aerospace programs, the need for versatility in inspection and testing capabilities is growing.

Read MoreNondestructive inspection methods available to composites manufacturers

An overview of composite laminate inspection techniques ranging from manual testing methods to more advanced, noncontact options.

Read MorePortable digital ultrasonic imaging achieves in-service, field and manufacturing inspection

CAMX 2023: 2D array ultrasonic NDT for composites, metals and other materials is made possible through Dolpitech’s dolphicam and dolphicam2+ matrix transducer technology.

Read More