Composites Use in Aerospace

Advantages of building aircraft structures with composites, compared to metal, include light weight, high specific strength, superior fatigue properties, damage tolerance and the absence of corrosion. In the 1950s, Boeing began using fiberglass in its 707 passenger jets, and at the time the material made up about 2% of the overall aircraft by weight. Since then, Boeing, Airbus and other aircraft manufacturers have continued to increase this percentage with successive aircraft models. Today’s twin-aisle commercial aircraft such as the Boeing 787, first launched in 2009, and the Airbus A350 comprise approximately 50% composites by weight, largely carbon fiber-reinforced polymer (CFRP).

Latest Aerospace Articles

VIEW ALLNIAR, KraussMaffei cooperation enables efficient aerospace aircraft conversion

Incorporation of FiberForm advance’s NIAR ability to convert metallic components to fiber-reinforced thermoplastic versions in cargo aircraft.

Read MoreSpeak at CW’s New Space Tech Days event on Nov. 13

One-day online event in winter 2024 will feature six presentations exploring the increasing importance of composites in the evolving space market.

Read MoreGulfstream supplier awards recognize ACT Aerospace

Advanced composites manufacturer was presented with 2023 Supplier of the Year, Suppler and Small Business of the Year and the 2022-2023 Above and Beyond Award.

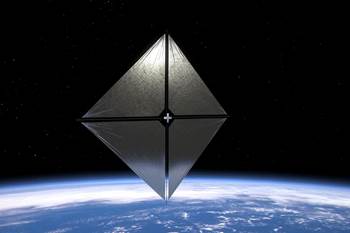

Read MoreNASA launches composite solar sail into space

Sunlight-based propulsion system, supported by carbon fiber-reinforced booms, will undergo weeks-long testing to demonstrate and verify its capabilities.

Read MoreAirbus establishes first A220 repair station in North America

M1 Composites Technologies has been chosen to provide repair services for the small single-aisle aircraft.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreKnowledge Centers

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORELatest Aerospace News And Updates

XB-1 supersonic jet authorized for flights exceeding Mach 1

FAA issues special flight authorization (SFA) for Boom Supersonic test flights, planned for later this year in the Black Mountain Supersonic Corridor in Mojave, California.

Read MoreRecoil Aerospace achieves certification for carbon fiber wildfire suppression system

T1000-E aerial firefighting technology earns supplemental type certification (STC) from the FAA for installation on Airbus Super Puma helicopters.

Read MoreComposites support Pilatus PC-24 payload capacity, flight range

More than 700 modifications were achieved under the Payload Range Increase Program to deliver increased range, payload and interior comforts.

Read MoreWingcopter begins type certification for composite drone in Japan

Contended to be the first foreign company’s drone to be accepted for type certification, the Wingcopter’s approval would enable commercial BVLOS operations in populated areas.

Read MoreWing-in-ground trials to commence for composite AirX Airfish craft

ST Engineering and the Maritime and Port Authority of Singapore (MPA) are collaborating to advance single- and dual-engine AirFish 8 prototypes.

Read MoreFAA investigates fresh concerns over 787 aircraft production

A Boeing engineer has claimed that the Dreamliner’s composite fuselage assembly process is flawed, raising questions about the aircraft’s structural integrity.

Read MoreFeatured Posts

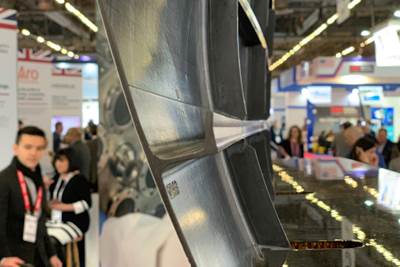

JEC World 2024 highlights: Forwarding initiatives surrounding sustainability and mobility

Themes at the forefront of JEC World 2024 included solutions for mobility applications and sustainable materials, technologies and processes for composites manufacturing.

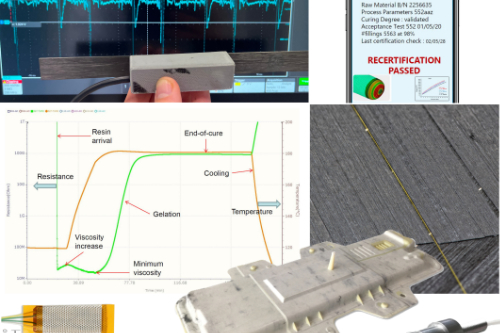

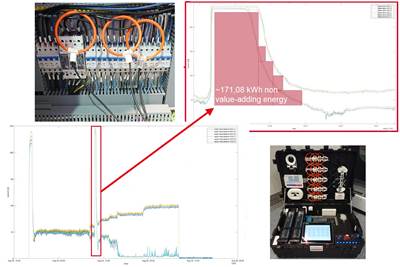

Read MoreMeasuring energy use to enable sustainable composites production

Airbus subsidiary CTC uses new technology to measure energy use in machine components and processes to optimize equipment, production lines and guide decisions for future composites.

Read MoreFrom the CW Archives: I see thermoplastics in your future

Thermoplastics are evolving quickly into larger structures and clearly will have a significant role to play in the next commercial aircraft program — whenever that’s announced. This edition of “From the CW Archives” looks back on a thermoplastics pioneer.

Read MoreEaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

WatchWho's ready for the Olympics?

With the 2024 Summer Olympics in Paris, this year’s JEC World is bound to be abuzz with talk of this year’s event — from the use of composites in sporting equipment to the roles they play in AAM.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

WatchFAQ: Aerospace

How are composites used in aerospace structures?

Since the 1950s, composites have been growing in use in commercial and defense aircraft, ranging from struts and tail components, to wing skins and fuselages, to engine components and propeller blades.

One of the largest challenges to adoption of composites by the aerospace industry is stringent standards especially for safety critical structures, necessitating time- and labor-intensive processes to qualify new materials for use on passenger aircraft.

Qualified and well-tested autoclave-cured carbon fiber and thermoset-based prepregs are most often used for many structures, though other materials and formats, including thermoplastic tapes, are also in development or use.

How are composites used in space structures?

At the time the Apollo capsule, which landed on the moon in 1969, was built by NASA, composites industry was still in its infancy and the materials were not yet in widespread use, though the Apollo capsule used early composite technology in the form of an ablative heat shield made from Avcoat, an epoxy novolac resin with silica fibers in a fiberglass-phenolic honeycomb matrix. A fiberglass honeycomb was bonded to the primary structure and the paste-like material was injected into each cell individually.

Since Apollo, advanced composites have evolved by leaps and bounds, and have played a significant role in space programs with use in launch vehicles, the space shuttle, satellites, space telescopes and the International Space Station.

Source: Composites in the race to space

.jpg;maxWidth=300;quality=90)