Composites 4.0

Plant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

Ginger Gardiner

Executive Editor, CompositesWorld

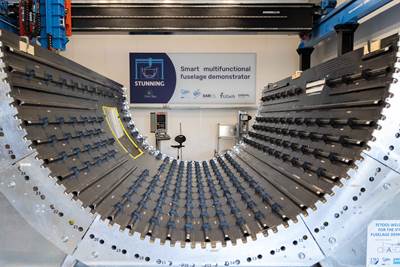

Bonded fastening meets the digital factory

Automation and XR tools aim to scale adhesive fastening for composites at next-gen aerospace production rates.

Read MoreIdeko participates in ROBOCOMP project for flexible, zero-emissions aerospace manufacturing

Precision and digitization contributions replacing heavy machinery with flexible robotic cells enable critical machining operations on carbon fiber parts and other production processes to be adapted and scaled.

Read MoreFLASHCOMP framework presents zero-defect, zero-waste composites manufacturing approach

In a published paper, project partners show how eco-efficiency can move from abstract ambition to practical decision-making, revealing waste as a symptom of deeper process inefficiencies.

Read MoreCompSTLar project turns TPC materials into their own SHM systems

SNAPSHOT: The CompSTLar project is using laser-induced graphene to create seamless sensors within structural parts, combining data with simulations to enable virtual stress tests for in situ monitoring and prediction.

Read MoreGENEX project final event presents findings in digital twins, smart manufacturing and composites repair

In-person event scheduled for Feb. 17-18, 2026, in Spain features a dynamic agenda, round tables to foster dialogue and a technical visit to Teruel Airport.

Read MoreDiMAT launches unified digital platform to simplify access to advanced manufacturing toolkits

The platform makes all available toolkits accessible through a single secure identity provider to eliminate the need for separate credentials, fragmented billing systems or disconnected security models.

Read MoreModular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Stewart Mitchell

Contributing Writer

ST Engineering MRAS pursues nacelle innovation via automation, integration and digitalization

The company’s engineering heritage in metal and composite nacelle and complex structures, combined with continuous investment in process automation and digital manufacturing, provides a foundation for future collaboration.

Read MoreAcceligence, Cetma DiMAT pilot project proves UAV concept development for SMEs

Digital twin technologies, high-fidelity simulation development and use of more sustainable materials de-risk and enable design to validation of UAV composite structures more rapidly, lowering entry barriers.

Read MoreUniphy raises £3 million for smart surface technology

Already trialed by companies like Hyundai, these touch-interactive surfaces offer safer options for dashboard controls in cars, appliances and more, even when used on composite surfaces.

Read MoreModular, hybrid machining centers with intelligence for complex composites

Machine Tool Camp’s purpose-built systems combine CNC machine centers and robots with specialized machining tools, clamping and configuration, automating steps before and after, including data integration, to empower manufacturers for the future.

Read MorePost Cure: TFP supports high-performing UAV wing preform development

The AMRC’s UAV concept is a complex design and manufacturing challenge that provides a shareable testbed, demonstrating the institute’s ability to develop and refine its expertise through a digital thread.

Read MoreSiemens, Ducati extend partnership to advance innovation

Siemens Xcelerator Platform helps extend racing innovation to production bikes, reduces time for complex composite parts and enables remote design/3D printing at track, digital twin and faster development.

Read MoreThermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

Ginger Gardiner

Executive Editor, CompositesWorld

Altair 2025 Enlighten Award winners, runner-ups push automotive boundaries

Hemp nylon-reinforced PA6 automotive exteriors, TPC acoustic elements, glass fiber stator cooling design and other innovations are recognized for their sustainability focus, holistic capabilities and lightweight designs.

Read MoreAltair, NIAR sign MOU to build aerospace innovation space

Collaboration will expand digital twin adoption, empower aerospace startups and speed up product development and certification processes.

Read MoreStack3d invests in, integrates CEAD Hybrid Flexbot

Stack3d pairs the LFAM FlexBot with its own R&D and materials processing capabilities to offer rapid, end-to-end production from prototyping to low-volume manufacturing.

Read MoreOtto Aerospace develops AI model for Phantom 3500 business jet aerodynamics

Tailored AI model will enable detailed aerodynamic analysis of current and future Otto aircraft configurations, streamlining design speed, precision and informing the aircraft program’s composite structures.

Read MoreHoly Technologies selects Plataine to scale up smart composites production

Plataine’s AI agents for scheduling and traceability will enable Holy Technologies to optimize serial production plans, reduce manual effort and build a scalable foundation for future growth.

Read MoreXitadel XIPA imparts more intelligent CAE simulation workflows

Automated preprocessing, FE model building and postprocessing are powered through machine learning and Gen AI tools, supporting enhanced speed, accuracy and efficiency.

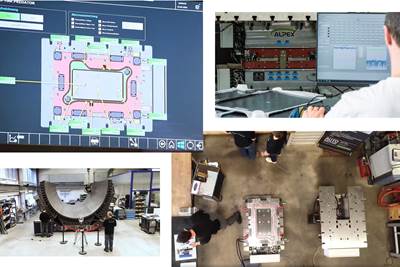

Read MoreDigitizing tools for composites production

Alpex Technologies focuses on industrialization, process and part intelligence and biocomposites in its next generation of tooling systems.

Ginger Gardiner

Executive Editor, CompositesWorld

Daher ODDICEA 2 project gains support to boost decarbonization of TPC production activities

Renewed financial support from France’s Pays de la Loire region will build on technological Industry 4.0 advances made in the project’s first phase for Daher’s Nantes facility, which has already delivered tangible results.

Read MoreUniSQ, iLAuNCH Trailblazer program drive digital twin innovation for composite repairs

Working with Boeing Australia, Memko and Dassault Systèmes, the University of Southern Queensland (UniSQ) has developed a digital twin via the 3DEXPERIENCE platform, digitizing processes that could lead toward more efficient and effective maintenance, repair and operations of future fleets.

Read MoreHorizon Europe projects present webinar for advancing aviation digitalization, composite technologies

Free webinar on Sept. 24, 2025, brings together members from DEMOQUAS, GENEX and TOSCA to delve into how these projects are contributing to safer, more efficient and environmentally responsible aviation technologies.

Read MoreSmart composites equipment advances aerocomposites innovation

CAMX 2025: From fiber to flight, Broetje-Automation innovates composites manufacturing with integrated AFP, drilling and sealing technologies.

Read MoreAnsys launches 2025 R2 with enhanced simulation, accessibility and AI

Ansys 2025 R2 amplifies human ingenuity with AI-driven tools and features that simplify simulation adoption, encourage collaboration and boost productivity across teams.

Read MoreSeoul National University VABS to design UAM, rotorcraft blades

University conducts research to establish conceptual and detailed design methodologies applicable to composite UAM systems and to develop digital twin technologies that can be used in aerospace.

Read More