Fabrics/Preforms for Composites

Composite fabrics or preforms serve as the foundation for creating composite materials, comprising carefully arranged layers of fibers or textiles before they are infused or coated with a matrix material. These fabrics or preforms come in various shapes, weaves, and orientations, allowing engineers to customize the material's properties based on specific application requirements. They play a pivotal role in determining the final characteristics of the composite, influencing factors like strength, flexibility, and weight distribution.

Latest Fabrics/Preforms Articles

VIEW ALLToray completes NCAMP qualification for Cetex low-melt PAEK

Toray Advanced Composites builds consistency and performance of its fabric-based TPC material while broadening its industry adoption and streamlined integration into certified aircraft structures.

Read MoreMetyx Metybond self-adhesive reinforcement achieves clean, efficient composite layup

Directly integrated adhesive on carbon, glass or hybrid multiaxial fabrics enables clean repositioning, uniform adhesive distribution and improved edge stability.

Read MoreShawmut Insights system enables automotive textiles, composites LCA visibility

Shawmut Corp. is helping its automotive partners make smarter material choices through high-resolution environmental data for warp knit headliner composites, laminated fabrics and other textile systems.

Read MoreAngeloni Group completes Selcom Multiaxial Technology merger

Acquired in 2022, Selcom and Angeloni Group are now operating as a single company with enriched composites expertise.

Read MoreTeijin Carbon, A&P Bimax TPUD braided fabric meets scalable composites manufacturing goals

A combination of Teijin Carbon’s UD thermoplastic tapes and A&P Technology’s braided fabrics translates into a PAEK biaxial fabric with minimal crimp, high drapability and other rate-enabling qualities.

Read MoreVerretex, Ryse Energy confirm use of rGF textiles as drop-in wind blade materials

Pilot trial at Ryse’s Spain facility required no alterations to production equipment or schedule when using the recycled glass fiber textile, with strength, stiffness and compliance targets achieved.

Read MoreKnowledge Centers

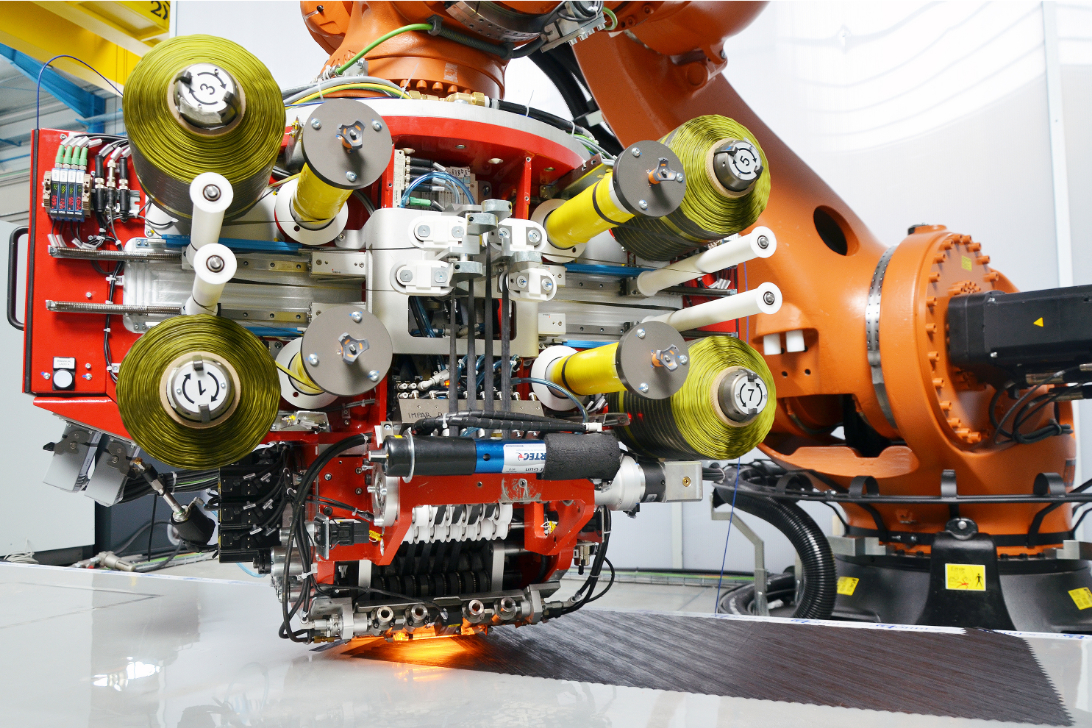

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORELatest Fabrics/Preforms News And Updates

DITF launches €4.2 million recycling projects to advance fiber, textile circular economies

The initiatives focus on creating industrial-scale processes for recycled high-performance fibers and transforming textile waste into high-quality yarns.

Read MoreRWC completes prototype radome using Renegade NCAMP-certified composite

Completed prototype for Georgian Aerospace uses a low-dielectric epoxy prepreg on quartz fabric, which has passed radio frequency testing with results equivalent to traditionally higher-cost, low-dielectric matrix options.

Read MoreBraided composites enable low-cost, high-rate fabrication

CAMX 2025: A&P Technology highlights its QISO and slit tape thermoplastic material capabilities through customer examples and industry applications.

Read MoreComplete solutions support reinforcements, consumables, plug and mold production

CAMX 2025: Attendees can discover how Metyx continues to support composites manufacturers with production-ready innovations, including Matvantage Plus, Matvantage PV, Metybond and Metycalc.

Read More3D weaving capabilities achieve complex shapes with reduced labor times, costs

JEC World 2025: The specialized engineered woven fabrics company displays film-infused 3D woven joints, woven TPS and woven composite 3D structures.

Read MoreComposite surfacing veils improve finish, function

JEC World 2025: James Cropper streamlines composites production through the launch of Surfacetec, improving fabrication efficiencies, part functionality and targeting sustainability.

Read MoreFeatured Posts

Carbon fiber/flax landing gear achieves 54% weight reduction via tailored layup optimization

Fuko’s Biogear showcases how strategic composite material distribution and natural fiber damping properties can lightweight and enhance critical aerospace structure performance.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreDesigning an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

WatchRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

WatchHybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

Read MoreUnderstanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read More