Electroimpact Inc.

Composites Automation

4413 Chennault Beach Rd.

Mukilteo, WA 98275 US

425-348-8090

sales@electroimpact.com

electroimpact.com

About Electroimpact Inc.

Electroimpact: Pioneering Aerospace Composites Automation

Electroimpact is a global leader in aerospace automation, renowned for its engineering-driven approach and deep expertise in composite manufacturing. With a strong concentration of engineers and a vertically integrated workflow—from concept to customer acceptance—Electroimpact delivers cutting-edge solutions with minimal bureaucracy.

The company designs and integrates advanced automation cells for composite part fabrication, machining, inspection, and assembly. Its technology portfolio includes:

• Automated fiber placement (AFP) and automated tape laying (ATL)

• Large-scale additive manufacturing and continuous fiber 3D printing

• Ultrasonic non-destructive inspection (NDI)

• Robotic pick-and-place systems

• Composite machining and laser ablation

• Automated tool cleaning and bond preparation

• Conformable tooling and forming equipment

• High-speed composite drilling and fastening systems

Electroimpact specializes in adaptive manufacturing cells featuring modular quick-change process heads. These heads—ranging from AFP, ATL, ultrasonic cutting, stitching, pick-and-place, NDI, to metrology—can be swapped in under 90 seconds, enabling unmatched flexibility and efficiency in production.

Beyond hardware, Electroimpact offers consulting services for factory and cell layout, as well as design for automated manufacturing. Their in-house suite of equipment supports full-scale prototyping and material development, empowering clients to rapidly iterate and validate composite parts and assemblies.

IS THIS YOUR COMPANY?

Video Gallery

AFP Head Shell Game Head Change

Automated Fiber Placement system for high volume production. Has shared service area for multiple machines to access process ...

December 16, 2025

15kghr Pellet Extrusion Water Soluble Polymer with Carbon.

Quick video showing out pellet extruder processing our machinable water-soluble material systems. This material completely ...

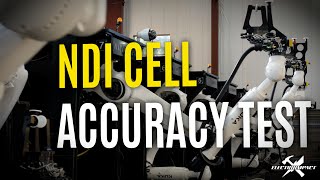

Electroimpact NDI Cell Accuracy Test

NDI Cell Accuracy Test Our NDI (Non-Destructive Inspection) cell undergoes rigid body movement accuracy testing before it even ...

HALF TON 3D Printed AFP Tool

Electroimpact's SCRAM (Scaled Composite Rapid Additive Manufacturing) cell brings together 3D printing, machining, sanding, ...

6-Axis Rocket Nozzle 3D Print With Trim And Washout

Hybrid SCRAM cell showing build of rocket nozzle type part with captured tooling features. This build features water soluble ...

All-Electric Flexriveter by Electroimpact

Flexriveter – All-Electric. Portable. Shop-ready. The Flex Riveter is a fully electric, production-grade riveting machine designed for ...

EDR Pulling Test #automobile #aerospacetechnology #manufacturing

Engineering Marvel: The Largest AFP Machine Featuring AFP 4.0

In collaboration with Rocket Lab, we've engineered and delivered the largest, fastest Automated Fiber Placement (AFP) machine ...

NexGen UAV Serpentine Intake Duct Print

NexGen UAV Serpentine Intake Duct Print using the Scalable Composite Robotic Manufacturing (SCRAM) System is a ...

C-Axis Programmable Work Stand by Electroimpact

Electroimpact Programmable Multi-Height Work Platforms! Key Features: ✓ 25x Servo-Driven Slide-Out Floors for seamless ...

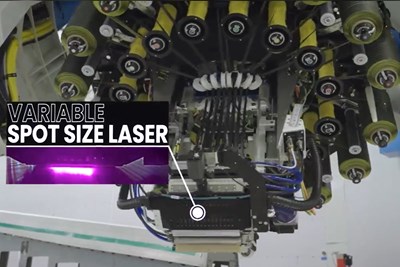

AFP Tech VSSL (Variable Spot Size Laser) Heater

The patented VSSL (Variable Spot Size Laser) by Electroimpact's #AFP Group. True digital heating and placement of composite ...

Electroimpact C-Axis Programmable Work Stand

Electroimpact Programmable Multi-Height Work Platforms! Key Features: ✓ 25x Servo-Driven Slide-Out Floors for seamless ...

Electroimpact Automated Bond Tool Cleaning Cell

Electroimpact's Dry Ice Blaster shoots dry ice pellets at 4 lbs./min for powerful, seamless tool cleaning, effectively removing old ...

Electroimpact E6000 installing lockbolts

Hand Held EMR Riveter Demo

Electroimpact E6000 Wing Riveting Machine #72

A rotation around toolpt

Rivet cycle view under clamp table

E8000 Squeeze Riveter Injector

Combined A&B rotation around toolpt

Electroimpact Fashion Show

B rotation around toolpt

Rivet cycle view from side

Rivet cycle view from behind oper station