Large, high-volume, infused composite structures on the aerospace horizon

Infused carbon fiber composite structures are not new, but they have never been built at the rates anticipated for next-generation, single-aisle aircraft. It is a daunting prospect — but a feasible one.

When Boeing and Airbus decided 15 years ago to fabricate major structures of, respectively, the 787 and A350 twin-aisle aircraft from carbon fiber composites, myriad choices were made by both companies about resin type, fiber format and manufacturing process. Much of this decision-making was driven by material trade studies, technologies available at the time, material and capital equipment costs, and internal and supplier manufacturing capacity, as well as the expected build rate of the aircraft.

When it came to wing structures — wing box, spars, ribs and skins — the decision was a simple one, at least compared to decisions regarding fuselage structure fabrication. The long, moderately contoured surfaces of wing structures were a good fit for automated tape laying (ATL) and automated fiber placement (AFP). These systems are adept at accurately and consistently laying large amounts of prepreg over large areas quickly. And, the fact that the epoxy resin matrix used in these prepregs required curing in very large autoclaves was just part of the state of the art at the time — the cost of the process. Further, the autoclave has a long history of very effectively consolidating composite laminates and achieving the critical sub-1 percent porosity levels that the aerospace industry demands.

Much of this logic remained in place as late as 2013, when Boeing launched the 777X. It features what are, currently, the largest carbon fiber composite wings in aerospace history, with a total wingspan of 72 meters. These are being manufactured at Boeing’s wing fabrication plant in Everett, Wash., U.S., using Electroimpact AFP systems and the world’s largest autoclaves — 8.5 by 37 meters — provided by ASC Systems (Valencia, Calif., U.S.).

As the aerospace industry looks to the future, however, the continued dominance of prepreg-based fabrication for wing structures is less certain. The infrastructure required for prepreg storage (freezers), along with the chore of managing prepreg expiration data, dulls the appeal of the material. On top of that is the production bottleneck of assembling large, complex, individually cured structures.

If, in fact, Boeing announces the New Middle Aircraft (NMA or 797) this year as expected, and if Boeing and/or Airbus decide in the next five years to design replacements for the 737 and the A320, a host of new material and process economics will have to be considered. The 737 and A320 alone are the most profitable for both companies, and with production volumes for each plane anticipated to be as many as 100 per month, they are sure to be manufactured at rates that give even the staunchest composites advocate pause.

It’s well understood that aluminum and carbon fiber are in the running at both companies for fuselage and wing structures. And diving even deeper, carbon fiber composites under consideration run the gamut from traditional prepregs applied all around to thermoplastic composites for the fuselage (see “Thermoplastic composites: Poised to step forward”) to infused composite structures for the wings.

Moving away from prepreg technology will require significant investment in time, research, equipment and people to prove the alternative technology’s viability and then get it qualified. Prepreg, despite its drawbacks, remains alluring for two big reasons: First, many aerospace prepregs are already qualified, and in aerospace, qualification is a black hole that consumes money and time. Second, prepregs are supplied with resin and fiber content in precisely controlled ratios, which takes a variable out of a manufacturing process that is already loaded with variables.

The siren call of infusion

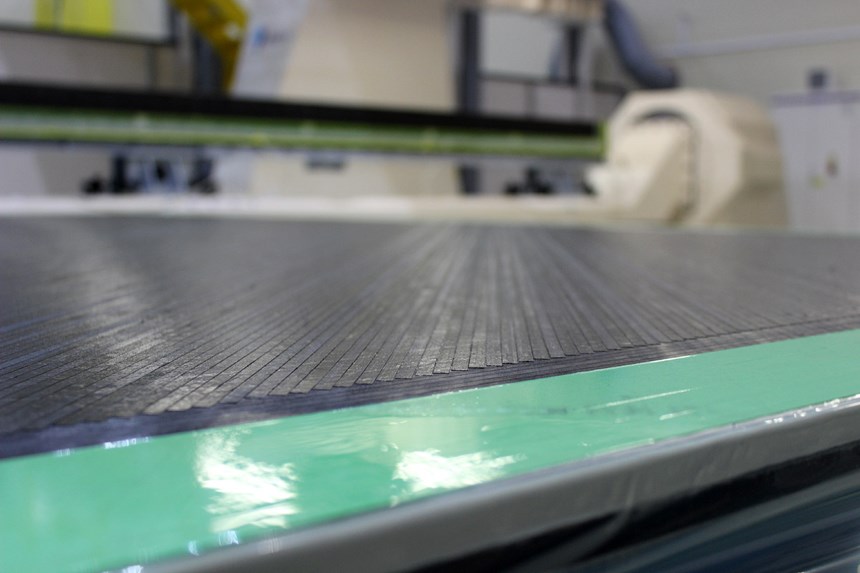

The benefits of resin infusion derive primarily from the fact that it is an out-of-autoclave (OOA) process. Instead — and very simply — dry fiber reinforcement, either in unidirectional (UD) or multiaxial/non-crimp fabric (NCF) format, is cut, kitted, placed in a mold, preformed, vacuum bagged and then infused in an oven with a one-part or two-part thermosetting resin matrix. Infused structures can be co-cured, which allows multi-component parts to be fabricated as a single piece. However, the lack of autoclave and the dependence on atmospheric pressure to achieve consolidation increase the complexity potential of the process.

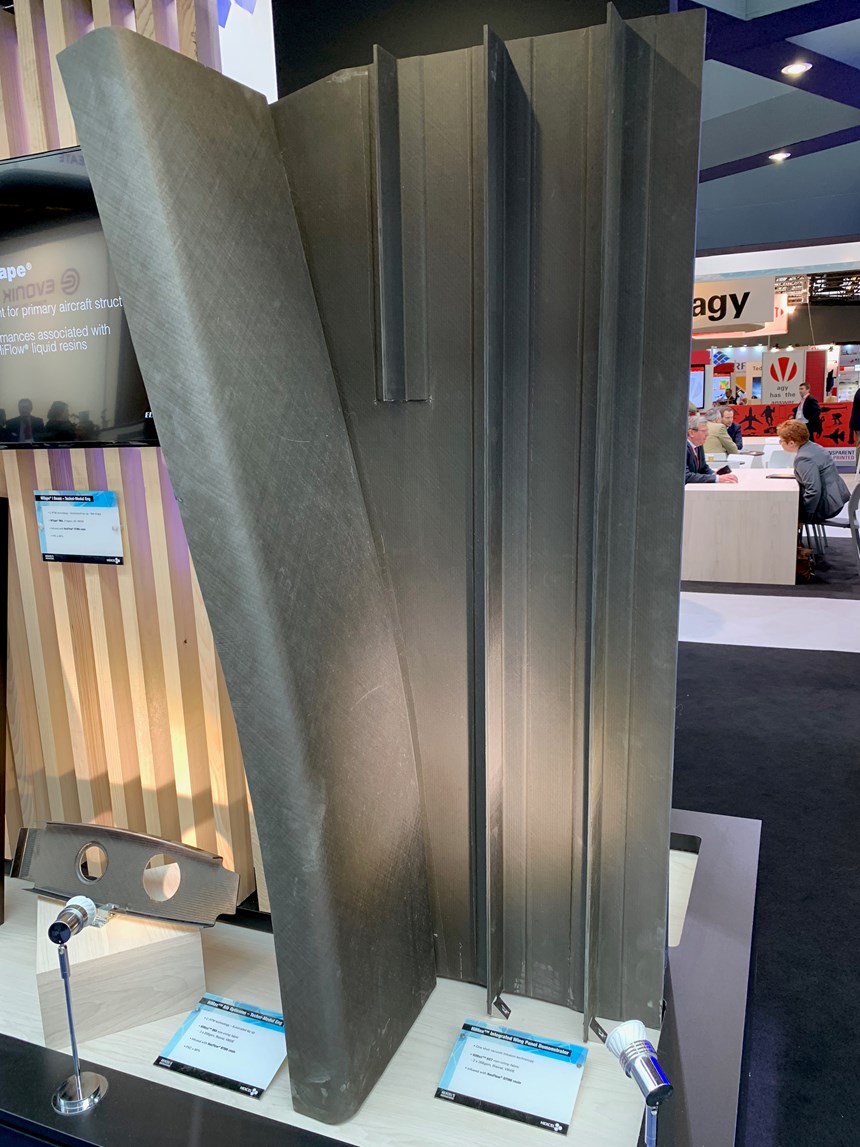

That said, infusion is not new to commercial aerospace, and although most infused aerostructures have, traditionally, been smaller (flaps, pressure bulkheads, etc.), large, fully OOA, infused structures have been developed. Most notable among these are the cargo door for the Airbus A400M military transport, which entered the market in 2010; the Boeing 787 wing movable trailing edge made with the patented CAPRI process; the pressure bulkhead for the Airbus A380, made with resin film infusion; and the wings and wing box of the MS-21 single-aisle commercial airplane, developed by Russian aerospace OEM Irkut. The MS-21 is currently in flight testing and is expected to enter service in 2021.

Worth mentioning as well are the wings for the single-aisle Airbus A220, which bridge the infusion/autoclave gap. The A220 was developed by Bombardier as the CSeries aircraft, until the program was sold to Airbus in late 2017, and then renamed in 2018. The A220 features infused wings that are subsequently autoclave-consolidated at Bombardier Aerostructures and Engineering Services in Belfast, Northern Ireland. The A220 wings use Teijin’s TENAX carbon fiber; Teijin (Tokyo, Japan) and Bombardier in early 2019 signed a contract extension for the wings through 2025.

Because the MS-21 wings are still in early production, these structures are looked to first when aerospace composites experts think about infusion for next-generation aircraft. AeroComposit (Moscow, Russia), which manufactures the MS-21 wings, has spent about a decade working with European and American supplier partners to develop the materials, tooling, automation and processes used to fabricate the structures that comprise the wing. The result is a highly integrated — wing skins, stringers, spars — structure that obviates the need for much of the assembly required of wing structures made with autoclave-cured prepregs. That said, AeroComposit told CompositesWorld in late 2018 that “the full manufacturing cycle of composite parts, starting from the layup of the preforms and until they are delivered for assembly, takes, as of now, approximately two months.” Infusion and cure take 20 hours. This is what gives OEMs pause.

Torsten Lorenz, principal of Consultants TWL (Daubach, Germany), worked with FACC (Ried im Innkreis, Austria) to help AeroComposit develop the base infusion processes and system used to fabricate the MS-21 wing structures. Previous to that, and later, he worked for Boeing at its Munich operations and Airbus (EADS at the time) at its Augsburg, Germany, location to help those companies develop infusion processes, including Airbus’ well-known Vacuum Assisted Process (VAP). Lorenz says there is a tendency among some engineers within the aerospace composites world to think about infusion only in terms of cost or time units.

“Over time, I have learned that infusion is not one process,” he contends. “And it is not a cheap process, but it does produce much less waste, and the fact that it uses dry fibers makes it much easier to work with. The key is not infusion itself, but the entire process. You must, every time, look at the total process — the total system.”

What are the benefits of that total process? Lorenz points to integrated structures, reduced assembly time, better dimensional conformity, minimal or no shimming, a better non-destructive inspection (NDI) pass rate and minimal material springback. “Typically, with prepregs,” he says, “you assemble, check for gaps, disassemble, shim, reassemble, check for gaps, disassemble, shim, etc.” Some engineers fail to see how infusion is cheaper and better, he says, particularly given the long infusion time for large structures. “But at the end, you need the total cost.”

By Lorenz’ estimation, AeroComposit, because of its work on the MS-21 wings, is about a decade ahead of the rest of the aerospace composites world in the development, application and optimization of infusion for large aerostructures. “The Russians are learning day by day and are constantly optimizing. They are way ahead,” he says.

The apparent head start that AeroComposit has with infused wings for the MS-21 likely means that there will be some technology transfer to China as well, thanks to joint ventures between the two countries. United Aircraft Corp. (UAC, Moscow), which owns Irkut, has created a 50-50 joint venture with Commercial Aircraft Corp. of China Ltd. (Comac, Shanghai) called CRAIC. CRAIC is working on development of the 929, a twin-aisle, twin-engine passenger aircraft, similar to the 787 and A350, that is projected to enter service in 2027. Lorenz contends that this plane, given AeroComposit’s success with the MS-21, almost certainly will feature infused wings.

Cost and risk

Because the largest question mark surrounding large-structure infusion revolves around rate, it is reasonable to look more closely at the process and assess its viability as a high-volume fabrication process. Everyone interviewed for this report notes that as impressive as the MS-21 and A220 are, they still represent low-volume use of infused structures. Getting the process to the next level is within reach, but it will an expensive, arduous reach.

Rob Blackburn, director of application engineering at Solvay Composite Materials (Alpharetta, Ga., U.S.), says infusion’s viability depends on how quickly it can be industrialized. “It really comes down to cost of ownership and risk,” he says. “For infusion, it’s the ability to integrate complex structures. But this comes with risk — tooling, fixtures, the robustness of the process. Complexity and integration are key.”

Indeed, within the infusion process itself, there are material and design decisions to be made that can affect how suited it is for the application. Consider, for example, the choice between one-component or two-component resin. Most infusion processes use a two-component system, which combines epoxy and hardener just prior to infusion into the preform. The risk here is twofold: Resin/hardener dosing accuracy and exotherm. Exotherm, in particular, could be a challenge, given the large volume of resin a wing structure requires. In addition, the combination of resin and hardener at the mold initiates cure immediately, which limits infusion time.

For this reason, Lorenz prefers a high-temperature-cure, one-component resin matrix, which eliminates the variability of hardener dosing. It also allows the fabricator to infuse resin at a temperature high enough to minimize resin viscosity during injection and infusion, but not so high that cure is initiated. This provides the time needed to wet out fibers prior to start of cure.

Then there is the question of what is being infused. AeroComposit, for the MS-21 wings, uses only unidirectional fabrics — with automated fiber placement (AFP) — which help facilitate fiber wetout, but also necessitate a potentially more complex layup architecture. Dry fibers also can be more easily steered by AFP, which helps facilitate more contoured architectures. “That does open the design envelope and expand the intrinsic value of composites,” argues Blackburn. “That is where you start to see the value of dry-fiber architecture.”

The alternative is multiaxial, stitched non-crimp fabric (NCF), which provides a convenient quasi-isotropic fiber structure, but tends to generate more waste. “Keep in mind that at some point, you still have to introduce the resin to the fiber,” Blackburn says. “You have to deal with the physics of the fiber, permeability issues, the viscosity of the resin. Buy-to-fly ratios need to be watched. UD with AFP has a good buy-to-fly ratio and low waste. NCF is higher volume, but more waste.” Lorenz also notes that the presence of stitching in an NCF reduces total fiber volume, which can affect ultimate mechanical properties of the structure. “UD is a better approximation of prepreg fiber volume fraction and performance,” he says.

Still, there is research being done to improve the viability of NCF for infusion. Jason Gibson, chief applications engineer at composites distributor Composites One (Arlington Heights, Ill., U.S.), says thin ply NCFs are gaining traction, as are NCFs optimized for large aerostructures. For example, spread-tow, thin-ply specialist Chomarat’s (Le Cheylard, France) C-PLY product is a two- to four-ply NCF using 12K tow to 50K tow carbon fibers ranging from 100 to 1200 gsm (total weight). And multiaxial fabric manufacturer Vectorply (Phenix City, Ala., U.S.) has been working for eight years with Boeing and Mississippi State University on new NCF reinforcements that are optimized for large-part infusion.

Ultimately, assuming the technical challenges are solved, the virtues of infusion — material handling ease, OOA, integrated structures, reduced assembly cost — seem well positioned to propel the process into a future commercial aircraft. It will be up to the OEMs, however, to make that happen.

Wing of Tomorrow

Airbus, for its part, is executing the most overt effort to accelerate its infusion capabilities for next-generation aircraft, having launched its Wing of Tomorrow Programme. Wing of Tomorrow is a research and development effort run out of Airbus’ massive aircraft wing manufacturing facilities in Filton and Bristol, U.K. The program is being supported in part by the National Composite Centre (NCC, Bristol) and the Advanced Manufacturing Research Centre (AMRC, Sheffield, U.K.), as well as commercial partners like Northrop Grumman (through its Clearfield, Utah, U.S. facility, formerly Orbital ATK), GE Aviation (Hamble, U.K.), GKN (Bristol) and Spirit AeroSystems (Wichita, Kan., U.S.).

Richard Oldfield, CEO of the NCC, says the Wing of Tomorrow Programme’s goal is to develop a very high-rate commercial aircraft wing structure manufacturing process that is, in nearly every measurable way, an order of magnitude better than current wing manufacturing technology. This means better automation, fewer parts, better parts integration, faster cycle time, faster NDI and faster assembly. “The program seeks to achieve a fundamental step change in aircraft manufacturing,” he says.

The most daunting challenge facing Oldfield’s goal comes down to rate. Airbus is currently manufacturing the composites-intensive A350 at a rate of 10 per month. If, as expected, composites are used to fabricate wings for an A320 replacement, the likely rate of production, according to several sources contacted by CompositesWorld for this report, is 100 shipsets per month — that’s more than three shipsets per day. Can the infusion process be sufficiently optimized to meet that target?

NCC aims to find out. Oldfield says Wing of Tomorrow partners are working with, through and at the NCC in a phased program to develop infused wing spars, stringers and skins. (The wing box is being developed separately at AMRC.) Oldfield says NCC has been given, by Airbus, cost, rate and TRL targets for every component. Based on trade studies performed by NCC, says Oldfield, “Infusion seems like the technology with the most potential.” To that end, the center will develop integrated skin and spar structures, with infusion performed with an industrially capable resin system. All of this work demands significant space and capex resources; to that end, NCC is expanding its facilities for the Wing of Tomorrow project and adding 10 new pieces of equipment, including dry fiber placement machines, molds and metering systems.

The NCC effort will progress through fabrication of wings measuring 1 meter, 3 meters, 5 meters and several iterations up to 17 meters. Full-scale trials and testing of wing skins and spars, says Oldfield, are expected to commence in the third quarter 2019 and into 2020, with delivery for assembly into a full wing structure (wing box, skins, spars) expected by the end of 2020. Testing of the full wing is expected to be done through 2021.

“Our goal is to allow Airbus and partners to make [material and process] decisions when they are ready,” says Oldfield. “Is this the right technology choice for Airbus to make? The outlook is promising at the moment.”

Uncertainty at Boeing

Visibility into Boeing’s efforts to develop materials and processes for infusion of large wing structures is more opaque. Although the company declined to comment for this report, there are public signals being sent by Boeing that provide some clues about its interest in infusion.

First, although Boeing is adept with infusion, it has historically confined series fabrication of infused composite parts and structures to those that weigh less than 50 pounds. Most of the process development done for these parts has been performed at Boeing Australia (Melbourne), which manufactures the wing trailing edge flaps for the 787 using NCFs/fabrics and infusion.

In 2015, Boeing announced that it had selected Mississippi State University’s Raspet Flight Research Laboratory to host the company’s Stitched Resin Infused Composite Research Center, which, as the name implies, is focused on use of stitched, non-crimp fabrics in the infusion process.

In the meantime, as noted above, for the 777X Boeing doubled-down on the same — albeit updated — fiber-placed, autoclave-cured prepreg technology used to fabricate the wings for the 787. For Boeing to catch up to AeroComposit or Airbus in infusion R&D would require a level of personnel and capital equipment investment that the company, it appears, is not yet willing to make. In any case, if and when the NMA is announced, consensus among the experts consulted for this report is that the wings on that plane will use prepregged reinforcements cured in an autoclave. Beyond the NMA, a 737 replacement could be a candidate for infused wing structures, assuming significant advances in infusion development and understanding at the OEM.

A bright future?

Expect, over the next five years, significant global research and development to sort out resin, reinforcement, preforming, automation and other variables in an effort to increase reliability, speed cycle time and reduce overall complexity of large-part infusion. Beyond that five-year horizon, assuming technology continues to progress, high-rate infusion of commercial aircraft wings seems feasible within the decade. R&D investment as well as serious OEM interest demonstrate the promise this process holds. Says Blackburn: “I do believe the gap between autoclave and infusion is as close as it’s ever been.”

The Next Generation of

Aerospace Manufacturing

With the commercial aviation industry projected to double in the next 20 years, meeting the demand for passenger and freight aircraft will require new technologies and unprecedented manufacturing rates.

Learn more about the materials and processes that will shape next-generation aircraft in a collection of stories from CompositesWorld, Modern Machine Shop and Additive Manufacturing, available to read or download for free. Get it here.

Related Content

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)