Biocomposites demonstrated as drop-in material option for truck interiors

Ongoing trials from Volvo Trucks with Forvia Group and subsidiary Materi’Act aim to prove out and commercialize biocomposites made from waste oyster shells for future long-haul truck platforms.

Materi’Act’s latest injection molding compound portfolio, NAFILean Vision (pictured at top), was designed to blend recycled plastics with renewable reinforcements from hemp fiber to oyster shells in a visible surface material. One ongoing collaborative project is a demonstration of NAFILean Vision for the instrument panel of a future Volvo Trucks cab (current cab design pictured at bottom). Sources | Forvia and Volvo Trucks

In 2024, Volvo Trucks North America (Greensboro, N.C., U.S.) launched its all-new VNL Class 8 long-haul truck model, featuring a reimagined cab design aiming to maximize driver safety and comfort. One key supplier for the truck’s interiors is Forvia Group (Nanterre, France and Auburn Hills, Mich., U.S.), which helped design and currently manufactures the talc-filled polypropylene (PP) instrument panel and other cab surfaces.

The success of this partnership led to discussions between Volvo Trucks and Forvia on development of future interiors made from bio-based or recycled materials, thanks to Forvia’s connections with its sustainanable materials subsidiary Materi’Act (Villeurbanne, France and Dallas, Texas, U.S.).

“Our customers care quite a bit about sustainability and the environment, so we have been investigating use of more sustainable materials within our products for years. But the part really needs to perform first — durability is one of the biggest concerns, as these trucks are expected to last for a long time and travel a lot of miles,” says Jason Dabel, chief designer for interiors at Volvo Trucks North America. “For years, we struggled to find new materials that were just as good or better than the materials we currently have in terms of both performance and sustainability.”

Volvo Trucks plans to introduce a NAFILean Vision formulation as an interiors material option for a future battery-electric truck model.

Since its founding by Forvia Group in 2022, Materi’Act has formulated multiple commercial and trial materials reinforced with recycled plastics and biomass feedstocks. Its most recent is NAFILean Vision, a platform of injection moldable compounds comprising recycled plastics reinforced with visible bio-based feedstocks like hemp fibers, oyster shells, reeds and more.

Over the past year, the Materi’Act North America and Volvo Trucks North America teams have worked on developing a version of Materi’Act’s NAFILean Vision materials to serve as a drop-in replacement for the injection molded PP interiors that Forvia is already producing — with the goal of using the same tooling and process that Volvo Trucks has already invested in.

Developing a drop-in biocomposite that matches performance

For this first trial, Volvo Trucks targeted the vehicle’s instrument panel topper — the largest dashboard component, which is manufactured as one injection molded panel with molded-in color and surface texture. The current commercial version is manufactured from PP filled with 15-20% talc to provide strength and rigidity.

Forvia currently manufactures a variety of Volvo VNL interior components from talc-filled polypropylene. In future, Volvo plans to introduce more sustainable material alternatives like biocomposites. Source | Volvo Trucks

Guided by Volvo Truck’s specifications, Materi’Act worked through iterations of its biocomposite compounds, aiming to replace mined talc with a more sustainable, lower-carbon emissions reinforcement. As with all of the company’s current products, formulation was done at Materi’Act’s site in Lyon, France, and compounded at its Dijon, France production site. In this case, engineering and design support were performed by the company’s site in Dallas, Texas, which was formed in 2024 as the company’s first North American facility. The Dallas site currently manufactures simple filled and unfilled compounds, with the goal of expanding to produce Materi’Act’s full product portfolio including NAFILean Vision in the near future.

The trial was successful, resulting in a NAFILean Vision formulation comprising PP reinforced with up to 10% oyster shells fragments, sourced as an aquacultural waste byproduct.

Why oyster shells? James Leo Mazurek, general manager at Materi’Act North America, explains that the properties and behavior of the shells most closely mimic that of a mineral filler like talc. “With some bio-fillers, if you add them into the resin at too large of a rate, you can actually start to degrade the chemistry of the plastic and create weak zones in the part. But oyster shells [which are primarily made from calcium carbonate] do not degrade the polymer properties.”

Materi’Act says the biomass feedstocks for its NAFILean Vision materials are sourced from waste streams, like oyster shells discarded through the aquaculture industry. Source | Forvia/Materi’Act

The sustainability-minded benefit of oyster shells is that they are plentiful as a waste byproduct of the aquaculture and fishery industry. “We began looking into oyster shells as a possible reinforcement as the legacy of our initial hemp fiber-reinforced NAFILean product,” Mazurek says. “One reason to use hemp versus other plant-based fibers is that it’s not a food source, so you’re not in competition with those who are facing food insecurity. Similarly, the oyster shells we’re sourcing would otherwise have been thrown out as waste.”

The more sustainable material also behaves similarly to traditionally used ones within the production process. Demonstrator instrument panel toppers were manufactured by Forvia, which, Mazurek notes, found that no pre-blending, temperature or process changes were needed — the part was able to be manufactured with the same tooling and injection molding process as the current commercial panels.

In addition, the oyster shell fragments provided a unique surface aesthetic. “You can see the oyster shell fragments in the part — they’re distributed quite evenly, but it is still an organic pattern. So you get the benefits of the recycled, bio-based content and because you can also visually see it, it promotes the material to the customer,” Dabel says.

Early part-level performance tests have also indicated similar strength and scratch resistance properties as the original part, and will continue as the project moves forward.

Next steps: Adding recycled plastic and future commercialization

The current trial iteration of the material uses virgin PP, but it’s worth noting that the partners are also working toward a formulation using 10% oyster shell reinforcement and up to 25% post-consumer recycled PP. “If you go above 25%, you start sacrificing properties of this particular resin. So we want to start at a place where we’re confident that it will perform as well as virgin plastic,” Mazurek says.

Even with virgin PP, the parts are still considered to be fully recyclable, Mazurek adds. “It can be handled and re-compounded just like any other PP recycling.”

Volvo Trucks plans to introduce this NAFILean Vision formulation as an interiors material option for a future battery-electric truck model, including for the instrument panel topper and potentially other surfaces in the cab.

“When we’re ready to put that into production, we’ll have this tangible option for customers to see that use of sustainable materials for this application is actually possible and can be swapped in as a drop-in replacement,” Dabel says. “When we work on new products in future, we know now that we can pull from Materi’Act’s experience and use this trial as a starting point to work on new part designs incorporating bio-based reinforcements or recycled content.”

Related Content

Recycled carbon fiber composite panels power 40% lighter, durable semi-rigid solar panels

Designed for auxiliary power use while traveling via boat or RV, Italian startup Levante’s custom flexible or standardized semi-rigid solar panels combine the benefits of ReCarbon’s rCF and thermoplastics.

Read MoreScaling up thermoplastic composites recycling

Thermoplastic composites are always said to be “recyclable.” Netherlands-based recycler Spiral RTC discusses the process, challenges, applications and opportunities to building a real recycling ecosystem.

Read MoreCarbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

Read MoreDesigning and manufacturing turbine test nacelles

Michigan-based Ground Test Solutions (GTS) shares the design and manufacturing processes involved in building composite nacelle components used in testing jet and helicopter engines.

Read MoreRead Next

Evolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.

Read MorePost Cure: Natural mineral fiber biocomposite via AFP enhances implant integration

Arctic Biomaterials produces high-quality composite biomaterials incorporating a natural mineral fiber that is useful in medical and healthcare-related fields.

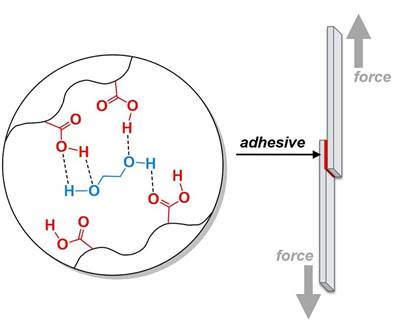

Read MoreResearchers explore biomimetic approach for making adhesives tougher

A team from Purdue University takes inspiration from sea creatures to produce stronger adhesives with weaker bonds.

Read More.jpg;width=70;height=70;mode=crop)