3M Advanced Materials Division

3M Company

3M Center, Bldg. 504-1-01

St. Paul, MN 55144 US

800-367-8905 | 800-367-8905

eamdcustomerservice@mmm.com

3m.com/advancedceramics

About 3M Advanced Materials Division

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

3M Advanced Materials Division Supplies the Following Products

- Microspheres

Editorial, News, and Products

-

A different Ox-Ox prepreg for faster, more affordable CMC options

Isovolta has developed silica fiber/alumina CERAPREG to enable ceramic matrix composite parts with long-duration service at 900°C and handling similar to epoxy prepreg, dielectric performance similar to quartz.

-

Composite products designed for efficiency, performance and sustainability

CAMX 2025: Whether through weight reducing or strength enhancements, 3M designs its microspheres, ceramic fibers, films and LSP materials and composite resins to meet its customers application demands.

-

RATH works with InVECOF project to mature oxide fiber production in Europe for CMC

Producer of Altra ceramic staple fibers aims to scale up continuous Ox fibers to compete with Nextel 610 and 720, and with its partners, offer improved fibers with creep resistance for higher temperature CMC applications.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

Pacific Coast Composites acquired by specialty chemical distributor

GracoRoberts anticipates offering current and new aerospace industry customers an extensive offering of composite products with short lead times.

-

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

-

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

Multi-composite thrust chamber aims to boost rockets, reduce cost for New Space economy

Black Engine uses new, microporous CMC liner for transpiration cooling and multiple lightweight composites in modular design that offers increased lifetime and lower maintenance versus current launch vehicle engines.

-

Northern Composites, Krayden discuss acquisition

Colorado-based distributor Krayden expands its composites industry presence with the acquisition of Northern Composites. Both companies talk about the deal.

-

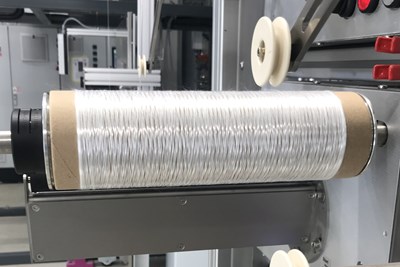

Leveraging towpreg to reduce the cost of CMC

High-denier, spread-tow Nextel 610 fiber and novel alumina matrix enable AFP production of Ox-Ox ceramic matrix composites.

-

Winners announced for the 2020 CAMX Award

Out of the finalists announced earlier last week, this year’s Combined Strength Award and Unsurpassed Innovation Award goes to 3M Co. and Might Buildings Inc. respectively.

-

CAMX announces 2020 award finalists

CAMX has announced its finalists for the 2020 CAMX Awards. It will hold the award ceremony Tuesday, September 22.

-

3M launches high-temperature, oxidation-stable Nextel ceramic fabric

Nextel 610 DF-13-4500 ceramic fabric allows ceramic composites to compete with metal components, with comparable performance and reduced cost.

-

3M introduces spray adhesive for infusion applications

3M has launched Hi Tack Composite Spray Adhesive 71 for infusion composites fabricating applications, particularly in industrial, marine and transportation markets.

-

Ceramic matrix composites: Hot engine solution

Disruptive designs for composites operation in 1093°C zones.

-

JEC World 2017: Show report, part 1

JEC World 2017 was, by almost any measure, the biggest and busiest JEC event yet, and exhibitors came with much to show the world of composites about innovation in materials, equipment and technology.

-

Composites for builders: Establishing structural foundations

Doors open to composites in residential and light commercial construction, above and below ground.

-

SMC: Old dog, new tricks

A sheet molding compound renaissance highlights new reinforcements, new fillers, new matrices, new opportunities.

-

Low-density SMC: Better living through chemistry

Proprietary sizing, special glass roving and microspheres strip 9 kilos of weight from Corvette body panels.

-

Structural work of art

Composites fabricator uses an innovative molding approach and digital techniques to actualize architect’s customized residential stairway.

-

Tooling (2015)

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

CAMX offers unprecedented new product access

CAMX 2014, Oct. 13-16 in Orlando, Fla., promises to be North America's largest ever composites trade show and conference. As a result, exhibitors are coming to the event with a wide array of new and existing materials, machinery, software and technology designed to help make composites fabrication faster, easier and more adaptable. CompositesWorld has been gathering information from CAMX exhibitors about what they will be featuring and introducing in their booths. This week's CAMX newsletter offers a preview of some of what you will find on the show floor.

-

BMI and benzoxazine battle for future OOA aerocomposites

Offering weight, cost and process advantages, these “hot zone” resins are moving down the thermometer and into out-of-autoclave structural applications and autoclavable tooling now dominated by epoxies.

-

Ceramic matrix composites heat up

Lightweight, hard and stable at high temperatures, CMCs are emerging from two decades of study and development into commercial applications.

-

Wind blades: Progress and challenges

Despite double-digit wind energy industry growth, turbine blade manufacturers and materials suppliers acknowledge a pressing need to reduce costs and innovate.

-

Composite-cored conductors: Holding the line

After a decade of incremental inroads, two different composite-cored electric power transmission products are connecting with those who specify for the grid.

-

Composite booth: ATM delivers "green" in more ways than one

Edra Equipamentos (Ipeuna, Brazil) has developed a composites-intensive automated teller machine (ATM) enclosure that is not only attractive and functional, but also environmentally sustainable.

-

WINDPOWER 2011 Report

Wind energy advocates, turbine builders and their suppliers, policy makers, and a growing number of wind-involved composites professionals gather where it all began.