Ceramic matrix composites: Hot engine solution

Disruptive designs for composites operation in 1093°C zones.

Aircraft engine manufacturers have spent years investigating exotic materials, in response to passenger, regulatory and cost pressures, that might reduce engine noise, emissions and specific fuel consumption (a measure of the efficiency of an engine design with respect to thrust output, largely related to mass or weight) in commercial passenger planes. Toward these ends, they have scrutinized super heat-resistant materials that show potential for reliable performance at the extreme temperatures (~1093°C) generated during the intended lifecycle and variety of conditions undergone by aircraft engines (see Aeroengine Composites, Part 1: The CMC invasion).

Among the candidate materials, which include nickel super-alloys, one winner appears to be ceramic-matrix composites (CMCs), different forms of which have been in R&D for years at General Electric (GE Aviation, Cincinnati, Ohio, US), Rolls-Royce (Manchester, UK), Pratt & Whitney (Hartford, CT, US) and other major aircraft engine manufacturers.

High-temperature pioneer

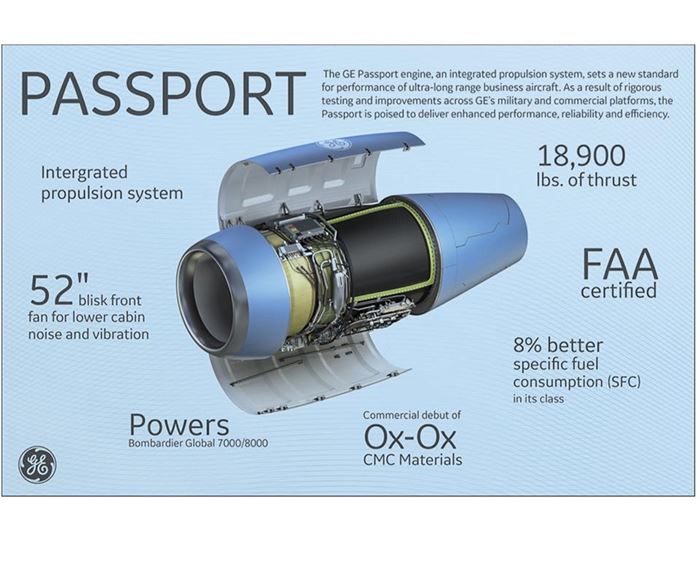

Composites Horizons LLC (CHI) in Covina, CA, US, a high-temperature materials pioneer, won an intensely contested contract from GE Aviation in 2010 to build CMC mixer, centerbody and engine core cowl components for GE’s newly FAA-certified Passport 20 engine, destined for Bombardier’s (Montreal, QC, Canada) long-range business aircraft, the Global 7000 and Global 8000, and similar models from other OEMs. At this writing, CHI has produced more than 300 ceramic components under the GE contract.

Acquired in 2016 by Precision Castparts (Portland, OR, US), part of the Berkshire Hathaway Group, CHI has focused on high-temperature composites since its founding in Covina, CA, in 1974. It began with available high-temperature organic polymers. “We were one of the early innovators of polyimide composites in the late 1970s and early 1980s, and have worked with engine and aircraft manufacturers on all the key polyimide materials,” says Jeff Hynes, CHI’s president and CEO. But these, too, had their limits. “Our impetus for investigating and pursuing higher temperature materials in inorganic ceramics, outside of the organic world, was the consistent and persistent interest of our engine customers in higher temperature realms than the organic composites could reach. So, our entire operation has really focused on high-temperature materials.” (See Resins for the Hot Zone, Part I: Polyimides.)

With its high-temperature experience and a clear, growing demand in aerospace and industrial markets for the highly prized characteristics of hot-zone materials, CHI made a strategic decision to fully invest in CMC technology. However, “you can’t simply take these materials and put them on polymer-matrix composite (PMC) cutters, or put them in a PMC layup room,” Hynes says, explaining, “You will have contamination issues.”

With this in mind, the company built a 3,252-m2 building in 2014, dedicated to CMC component manufacture. The facility includes an impressive array of CMC resources, including CNC cutters (Gerber Technology, Tolland, CT, US) with blades designed for cutting abrasive ceramic materials; laser projection systems (Virtek Vision International Inc., Waterloo, ON, Canada); a 5-axis CNC milling machine (Fooke GmbH, Borken, Germany); autoclaves (ASC Process Systems, Valencia, CA, US); a specialized 8 ft by 8 ft by 8 ft (512 ft3), 1093°C sintering furnace; and digital laser NDT infrared ash thermography equipment, designed by Thermal Wave Imaging Inc. (TWI, Ferndale, MI, US) and run under contract from CHI by X-Ray Industries (XRI, Troy, MI).

Further, Bill Roberts, a 32-year veteran of the Boeing Co.’s (Chicago, IL, US) Space Shuttle program — was brought in as VP for ceramic operations.

Benefits of CMC in engines, compared to metals

As noted, a significant characteristic of CMC is its ability to withstand a very hot engine and that engine’s very hot exhaust. That’s a significant advantage in this application because when a jet engine runs at high temperature, it typically discharges fewer emissions of carbon dioxide (CO2) and nitrogen oxide (NOx) — thus advancing the aviation industry toward an often elusive, but important goal.

Another advantage of CMC is that, like the less high-temperature-tolerant PMCs, it is flexible and can be formed into very tight radii — for example, the tight radii and complex shape of an engine mixer. This is in contrast to the difficulty experienced when forming less-flexible metals for this or similarly complex parts, Hynes points out.

Mixers are used on small- to mid-sized aircraft engines to improve the mix of the hot core-engine exhaust with the cooler bypass air (air driven by the engine fan that bypasses the core engine). The smooth, tight shape that can be realized in a CMC mixer helps mix bypass air and exhaust more efficiently. The more efficiently those airflows mix, the better the specific fuel consumption. This increases engine efficiency and reduces engine noise.

“For the same reasons, CMCs also resist acoustic fatigue [vibration] better than, for example, welded titanium,” Hynes says, particularly in designs such as the mixer. Metals that are bent or formed in very tight radii tend to exhibit fatigue failure, but CMC is far more forgiving and durable, Hynes explains.

CMCs “allow you to build numerous shapes with exotic geometries,” Roberts adds, “without the fatigue risk you would have in a welded joint.”

As a bonus, CMC contributes to lightweighting of the engine structure. “Oxide ceramics are about one-third the density of nickel alloys, with similar or even higher temperature capabilities,” Hynes says. “So using CMC can make a significant reduction to the overall mass of the engine structure.”

GE design of parts and materials

GE Aviation maintains a separate facility in Huntsville, AL, US, for production of silicon carbide (SiC) CMC materials used to make turbine shrouds, nozzles and other “superhot zone” parts for its LEAP and other engines, through a joint venture with Safran Aircraft Engines (Courcouronnes, France). For sake of cost control, however, GE turned to a different CMC for the Passport 20. “SiC/SiC is a more expensive material and the temperature requirement for the Passport 20 exhaust components did not dictate the need for the higher temperature capability that SiC/SiC provides,” explains Tim Shumate, CHI VP of sales and marketing.

For the CMC components of the mixer, centerbody and core cowl, GE designed CMC prepreg material using alumina oxide fibers and alumina oxide matrices — called Ox-Ox CMC — and subsequently qualified the prepreg for the Passport 20 as well as a number of military applications. The prepreg is produced to GE’s specifications by Axiom Materials Inc. (Santa Ana, CA, US). Axiom weaves the fabric for GE, using 3M Nextel 720 continuous-filament ceramic oxide fibers, produced by 3M Advanced Materials (St. Paul, MN, US). The woven fabric is then pre-impregnated with an alumina oxide matrix.

The ceramic matrix is a slurry of alumina and other fillers and materials. When the matrix is heated in an autoclave and then sintered, the fibers and matrix are fused together. This process differs from that for standard PMCs, where two very different organic materials, such as carbon fiber and epoxy thermoset resin, are combined and heat-molded into a new molecular structure. The fiber and matrix in Ox-Ox CMC materials have very similar chemical structures, derived from powders and various other mixtures, Hynes explains. When these materials are sintered and hardened, their chemical makeup remains the same.

The design load of these parts derives from the aeroloads from the engine core airflow and external airflow — primarily a pressure load, rather than tensile or compression, Hynes says. Like carbon or glass fibers, oxide fibers can be oriented in the layup to achieve a quasi-isotropic architecture.

Manufacturing Ox-Ox CMC parts

For the Passport 20 engine, CHI’s Ox-Ox CMC parts comprise the mixer, the exhaust centerbody and the engine core cowl. The mixer and centerbody are both part of the engine nozzle. For these, the Axiom multiaxial prepreg fabric is cut to pre-designed patterns on Gerber automated flatbed CNC cutters. An Ox-Ox CMC prepreg uses solvents that have a volatile ash-point, so they must be refrigerated until use. They, therefore, have a limited cumulative out-time at room temperature that requires strict control procedures.

The precision-cut patterns are hand-laid on custom metal molds, previously treated with a special mold release. Layup is assisted by laser projection systems provided by Gerber subsidiary Virtek Vision International. Molds were provided by GE or by AIP Aerospace (Santa Ana, CA, US), CHI’s previous owner.

The mixer assembly — the most complex of the components produced — is 965 mm in diameter and 610 mm long. The mixer is molded in a multi-segment metal tool that is assembled for layup and is then disassembled after autoclave cure to allow the tool to be safely removed from the part. After layup, the part is vacuum bagged using nylon bags from Airtech International Inc. (Huntington Beach, CA, US) and cured in an autoclave under high temperature and high pressure (details not disclosed) — and then de-molded prior to sintering. Because the autoclave cycle leaves the ceramic in the green state—that is, compacted but not fully cured — Hynes explains, “We have to be very careful in de-molding this complex part before it is fully hardened in the sintering oven.”

The engine exhaust centerbody is a cone-shaped structure approximately 460 mm in diameter (on the front end) and 610 mm tall. It fits inside the mixer and protrudes aft of the mixer trailing edge. For this part, the cut patterns are hand laid into concave (female) molds and covered with a caul plate — made from an undisclosed material — to apply and equalize pressure. It, too, is then vacuum-bagged, autoclave-cured and demolded before entering the sintering cycle.

The core cowl is made in four parts, each approximately 1.52 meters long and curved to form a cylinder that encloses the engine core. These parts, too, are laid up in single-sided, concave molds, covered with caul plates and vacuum bagged. And they, too, are autoclave cured, demolded and finished in the sintering furnace.

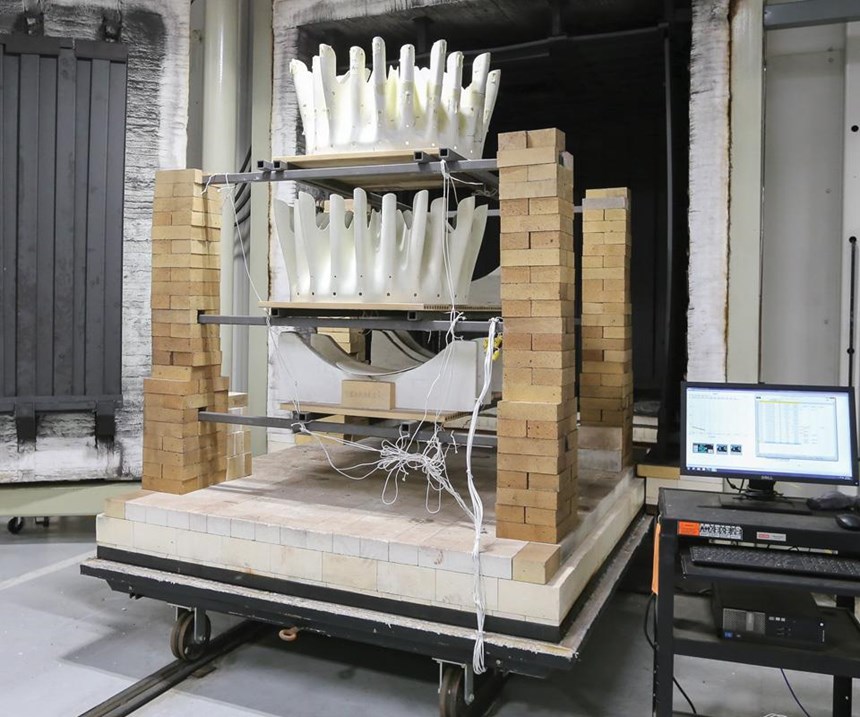

In each case, the cured parts are then transferred after demolding to the sintering furnace. The custom-designed furnace features a computer-controlled, removable floor, a design that protects workers from having to enter the furnace. After the parts are loaded, the floor is activated to automatically slide under the furnace and then lift up into position. After the loaded floor is set inside the furnace, the insulated door is closed and the furnace is brought to operational temperature. As the furnace reaches 1093°C, the ceramic matrix fuses and residual organic materials burn off.

After the parts are removed from the sintering furnace and cooled, they are transferred to a Fooke GmbH (Borken, Germany) 5-axis CNC milling machine for milling, grinding and drilling counterbores, using specially designed cutting tools.

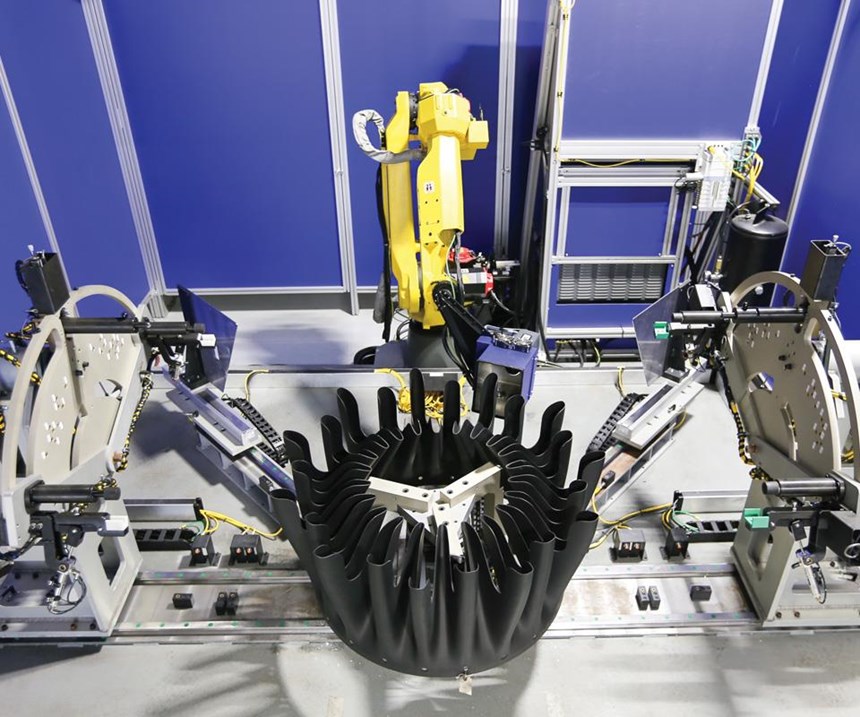

The next step is quality control: First the outside surfaces are measured, using a Romer CMM (coordinate measurement machine) from Hexagon Metrology Inc. (Cobham, Surrey, UK) to confirm surface dimension and shape. Next, they are subjected to nondestructive inspection (NDI) on site, using infrared ash thermography equipment. The automated inspection system includes a robot and various other articulating devices that enable the forward-looking infrared camera (FLIR) to maintain a direct line of sight on the complex part and scan 100% of each part’s surfaces to detect porosity and delamination. In ash thermography, a heat source, such as a brief pulse of light, is used to heat a sample’s surface while an infrared camera records changes in the surface temperature. As the sample cools, its surface temperature is affected by internal flaws, including disbonds, voids or inclusions, which obstruct the flow of heat into the sample.

Lastly, metal details and ceramic parts are assembled, using mechanical fasteners, and then the finished units are packed for shipment to GE, which does the final assembly.

Hynes notes that fastener technology for engine parts is intellectual property typically closely protected by OEMs because of the different coeffcient of thermal expansion (CTE) of materials found in engine assemblies. Although oxide CMC resists high temperatures in operation, its CTE is similar to that of aluminum. The thermal mismatch between oxide components that are attached to nickel alloys is, therefore, a significant design consideration.

Markets and applications

In 2015, with the GE contract well under way, CHI concurrently began developing its own Ox-Ox CMC matrix materials, designated AXC-610 and AXC-720. Hynes says CHI is currently using these materials in two other applications: one in aerospace, and the other in an industrial application.

Hynes further explains that in “looking for a lower cost alternative to the industry-standard ceramic fabric forms, CHI began working with Nextel fiber supplier 3M Advanced Materials and prepreg supplier Axiom Materials to test several oxide fabrics, using the AXC oxide matrix.”

Most Ox-Ox CMC work has been done using very fine (and expensive) 1,500 denier yarns, but 3M can supply higher denier yarns (3000, 4,500 and 10,000 denier), increasing the number of filaments in the tow bundle while keeping the same individual filament diameters. This results in a significant cost advantage in fiber production that can be passed along to the supply chain and part manufacturers. “It’s the same fiber,” Roberts clarifies, “but the tow bundles are larger, reducing the fabrication costs.”

It is highly recommended, however, that part contours and layup characteristics be carefully considered when selecting the lowest cost CMC fabric suitable for a specific application. For example, tight contours have been achieved using prepregs made with up to 3,000 denier, but are not recommended for 4,500 denier yarns. But gentler geometries are possible with the higher deniers.

The results of these investigations were reported in two papers. The first, presented by 3M, Axiom and CHI to the American Ceramic Society Meeting on June 2015 in Toronto, ON, Canada, was titled “Oxide-oxide ceramic matrix composites — enabling widespread industry adoption.” The other, presented at the United States Advanced Ceramics Assn. (USACA) meeting, January 2017 in Coca Beach, FL, US, dealt with “Designing with oxide-oxide CMCs: Understanding the price-performance relationship in new fabric designs.”

Using lower-cost fabric forms, the program successfully demonstrated mechanical properties equivalent to those achieved with more expensive industry-standard ceramic fabric forms, up to temperatures of 1177°C, Hynes says. In addition to woven fabric, Ox-Ox CMC tows, tapes or chopped fiber also can be made. The markets for such lower cost, higher denier Ox-Ox CMC materials include high-performance aerospace applications, as well as industrial, energy and, possibly, high-end automotive applications.

Less yields more

Ceramic-matrix composites are making a strong contribution to what some consider a disruptive advancement in aircraft engines, a game-changing transition to an integrated propulsion system that incorporates advanced materials and technology (including GE’s innovative carbon fiber composite fan case). The result has been an 8% reduction in specific fuel consumption, lower vibration and noise, significantly fewer emissions and long-range performance.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)