Arkema Inc.

Arkema

900 First Avenue

King of Prussia, PA 19406 US

800-225-7788 | 610-205-7000

arkema-americas.com

About Arkema Inc.

A global leader in thermoset resins, the company serves the global wood and industrial markets through a broad range of thermoset technologies, specialty products and technical support for customers in a diverse range of applications and industries.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Arkema Inc. Supplies the Following Products

- Adhesive bonding

- Adhesive bonding

- Aerospace, aircraft interior

- Automotive, body panels & substructures

- Coating and painting

- Coating and painting

- Curing agents, others

- Flame retardant

- Other additives/modifiers

- Other catalysts/promoters

- Other coating materials

- Other composite structures

- Other, Solvent-based

- Other, Water-based

- Protective

Editorial, News, and Products

-

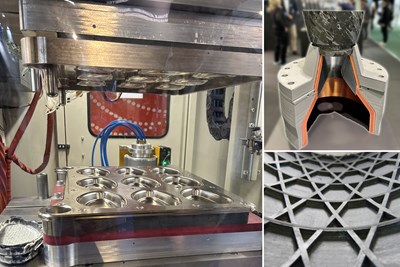

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Hexcel, Arkema present CFRTP aerospace demonstrator in HAICoPAS

Project optimized design and production of UD composite tapes reinforced with a PEKK matrix, using a continuous in-situ welding (ISW) assembly system.

-

European boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

-

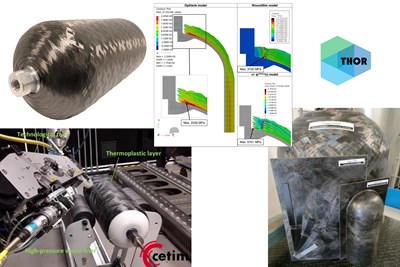

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

-

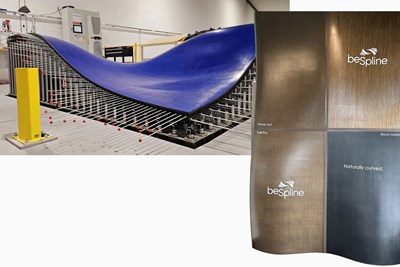

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

Thermoplastic composite, tube-shaped preforms for large-volume manufacturing

Starting with the sporting goods and bicycle market, French startup 3DiTex targets its continuous preforming system for thermoformable, thermoplastic composite tubes in complex geometries.

-

Fully recyclable composite mold incorporates Arkema Elium resin

Collaborative project with milling and tooling company Merritt Precision achieves sustainable fiberglass boat mold that meets manufacturing, recyclability needs.

-

Resins, additives, adhesives and 3D printing solutions

CAMX 2023: Arkema’s broad portfolio of products for composites fabricators aim to enhance performance, durability and sustainability.

-

NLcomp launches recyclable composite sailing boat Ecoracer30

Italian startup featured its 30-foot sustainable production boat at the Ocean Race Grand Finale in Genoa, Italy, citing the challenges, highlights and future related to its development.

-

JEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

-

JEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

-

JEC World 2023 preview

JEC World is the composites industry’s largest trade event, featuring exhibits, presentations and specialized pavilions covering the entire composites industry supply chain.

-

Continuous Composites unveils commercial CF3D Enterprise machine

Purchased by the University of Illinois Urbana-Champaign, the milestone was celebrated during a ribbon-cutting ceremony and technical symposium, highlighting the system’s ability to accelerate the R&D of composites manufacturing.

-

Arkema, CNRS open France-based lab for UV-curable material exploration

Accelerated photopolymerization research to benefit adhesives, 3D printing, composites, electronics and coatings applications, among others.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

-

Twenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

-

FMG releases market analysis on advanced materials

U.K.-based Future Materials Group (FMG) has issued a new report that assesses the outlook for and opportunities in the advanced materials sector.

-

Moving toward next-generation wind blade recycling

Suppliers, fabricators and OEMs across the composite wind blade supply chain ramp up existing technologies, develop better reclamation methods and design more recyclable wind blades.

-

Boston Materials expands into hydrogen fuel cells market with ZRT lightweight bipolar plates

In collaboration with Arkema, Boston Materials introduces its high-performance, recyclable material for boosting fuel cell performance and lowering costs.

-

Arkema introduces Clearstrength XT 151 toughener powder for epoxy formulations

The toughener is tailored to boost the durability and performance of thermosetting resins without compromising processability.

-

ZEBRA project launched to develop first 100% recyclable wind turbine blades

A cross-sector consortium has been brought together to demonstrate the relevance of thermoplastic wind turbine blades, with an eco-design approach to facilitate recycling.

-

CF3D technology developments for continuous fiber AM applications

Studies conducted by Continuous Composites, Lockheed Martin and the Air Force Research Laboratory advance aerospace applications of continuous fiber additive manufacturing.

-

Sustainability program leverages Arkema's Elium resin for fully recyclable fiberglass boat

Brunswick Corp. and fiberglass boat manufacturer Boston Whaler expect the composite hull and structural components to be fully recyclable, reducing disposable material and virgin raw material sourcing.

-

Arkema preps for powder coating resins lab opening in Cary, North Carolina late 2022

The new facility will focus on formulation and application/testing support for Arkema’s Reafree resins, including those made with polyester and PU resins, UV-curable products, additives and more.

-

METEOR project studies optimization of thermoplastic prepreg production

Completed project aimed at optimizing and reducing the cost and energy involved in CFRTP prepreg manufacture, with the end goal of industrialization.

-

Arkema doubles Sartomer photocure resins capacity in Asia

Increased production capacity reinforces downstream acrylics activities in Asia to support electronics, renewable energy sectors, and grow UV curing portfolio.

-

NREL explores novel manufacturing approach for next-generation wind turbine blades

3D printing of thermoplastic blades enables thermal welding and improves recyclability, offering the potential to reduce turbine blade weight and cost by at least 10%, and production cycle time by 15%.

-

SPE Automotive Division names 36 finalists for annual Automotive Innovation Awards Gala

Category and grand award winners selected by the Blue Ribbon judging round Oct. 1 will be announced during the gala on Nov. 10, 2021. Submissions are described below.

-

CAMX 2021 Show Daily highlights composite technology innovations

As the CAMX media sponsor, CompositesWorld reported on several new or improved developments on display, from CAMX Award and ACE Award winners, to the keynote speaker and interesting technologies.

-

RECONTRAS project validates use of microwaves and laser welding to obtain recyclable composites

Reseachers obtained a reduction in costs and energy consumption through the manufacture of three composite prototypes and confirm the feasibility of recycling and processing the resulting material.

-

Arkema acquires Ashland’s Performance Adhesives business, reaches new growth milestone

Ashland’s high-performance adhesives portfolio available to the U.S. is key to supporting Bostik’s long-term growth ambition and its aim for an EBITDA margin above 17% by 2024.

-

Continuous Composites closes $17 million Series A financing for CF3D

The financing round enables Continuous Composites to commercialize its CF3D product offerings, as well as advance and protect the company’s expansive patent portfolio.

-

NTU Singapore, Arkema manufacture carbon fiber helmets using Elium resin

Carbon fiber reinforcement increases stiffness, toughness of the helmet’s outer shell and allows it to absorb more impact energy over a longer period.

-

Multifunctional composite structures across end markets

Innovators find new ways to add functions — from anti-icing to 5G signal transmission to structural batteries and beyond — into structural composites.

-

Arkema acquires 10% stake in additive manufacturer ERPRO 3D Factory

Investment enables Arkema to accelerate new development opportunities for high-performance polymers and potential fiber-reinforced materials in additive manufacturing.

-

Arkema opens Center of Excellence dedicated to photocuring, photoinitiator technologies

U.K.-based facility will act as a collaborative space to develop and fine-tune energy curing challenges and solutions.

-

People in Composites: May 2021

Illium Composites, Boom Supersonic, Hexion, AOC, KraussMaffei, Composites Integration and SPE announce new hires within the composites manufacturing industry.

-

Continuous Composites awarded Phase II SBIR contract for full-scale unmanned aircraft wing

High-performance thermoset resins and continuous carbon fiber via the company’s CF3D process will be used to fabricate an organically integrated wing spar and rib configuration into a single component.

-

Continuous Composites, Siemens Energy apply high-performance materials for power generators

Continuous Fiber 3D Printing (CF3D) enables new designs for AM with thermoset GFRP composite and exceeds material requirements for generator components.

-

University of Delaware TuFF composite material shows high potential for UAM

High-performance, short-fiber composite offers aerospace-grade properties with the potential to offer costs and production rates similar to those found in the automotive industry.

-

Bostik launches online platform dedicated to construction professionals

Bostik Academy provides a broad range of information on flooring and sealing applications and technical support on four regional platforms.

-

Arkema launches global Start-up Connect program for responsible innovation

Program invites global startup companies specializing in advanced materials for transformative technical collaboration and pooling of expertise and innovation.

-

Commercializing UV-curable thermosets for continuous fiber 3D printing

Strategic partners Continuous Composites and Arkema/Sartomer are developing a library of photocurable resins for use in a variety of OOA, high-speed, high-performance composite applications.

-

Arkema acquires Colorado Photopolymer Solutions, grows 3D printing expertise

The acquisition will compliment the Sartomer line’s photocure resins product offerings and move Arkema further along to become a pure Specialty Materials player by 2024.

-

NREL, Arkema research recyclable, thermoplastic composite wind turbine blades

The National Renewable Energy Laboratory and partners aim to develop more sustainable, longer-lasting turbine blades that are less expensive to manufacture.

-

Continuous Composites opens demonstration facility for 3D printing composites

The new building demonstrates the company's patented Continuous Fiber 3D Printing (CF3D), and reflects the relationships it has built over the years with industry members.

-

Reprocessable thermosets and thermoplastic epoxies: An expanding landscape

New chemistries give thermosets new thermoplastic-like versatility.

-

Xenia carbon-filled compounds retain high tensile strength, easy processability

XECARB SL composites are the latest addition in the Xenia Materials family, retaining excellent dimensional stability and overall resistance.

-

Arkema strengthens strategic partnership with Continuous Composites investment

The contribution of Continuous Composites’ continuous fiber 3D printing technology will accelerate the innovation of 3D composite manufacturing solutions.

-

Proposed Fixatti acquisition reinforces Arkema thermobonding adhesives business

The proposed acquisition would strengthen Arkema’s global offering of hotmelt adhesive solutions and target its goal to become a pure specialty materials player by 2024.

-

Aimplas-led project develops thermoplastic prototypes

The RECONTRANS project adapts Arkema’s Elium thermoplastic resin for car, truck and rail applications.

-

Composites suppliers, fabricators respond to coronavirus

Companies across the composites industry supply chain share how the COVID-19 pandemic is affecting their businesses, and how they are available to help.

-

JEC Group announces 2020 Innovation Awards winners

The 13 winners were announced during a virtual ceremony on May 13.

-

9T Labs, Arkema present new manufacturing approach for small aerospace parts

The companies demonstrate cost-competitive series production of structural composite parts using carbon fiber/PEKK materials and additive manufacturing.

-

Arkema outlines growth plans in Specialty Materials

In a recent strategy update meeting, the chemical company said it will focus on growth on its Adhesive Solutions, Advanced Materials and Coating Solutions businesses.

-

Developing new solutions to multimaterial joining

Several recent IACMI partner projects focus on technology innovation related to challenges in multimaterial joining for the wind and automotive sectors.

-

Using mobile susceptors to innovate thermoplastic induction welding

IS Groupe and Arkema patent ISW for high-strength UD welds, temperature control and 50% less energy.

-

IACMI: Driving innovation in the advanced composites industry

Since its start in 2015, the Institute for Advanced Composites Manufacturing Innovation (IACMI) has come a long way in its mission of advancing composites innovation. CTO Uday Vaidya reflects on the past five years.

-

Arkema expands high-performance solutions to the 3D printing of composites

Arkema announces partnerships for innovative new solutions for manufacturing continuous fiber composite parts using 3D printing.

-

Arkema inaugurates Global Center of Excellence for 3D Printing in Normandy

The center is dedicated to additive manufacturing based on high-performance polymers, specifically powder bed fusion.

-

Continuous fiber-reinforced thermoplastics data added to CAMPUS database

The new data, which will be released in October, is the result of an ongoing material standardization and characterization effort led by German reinforced plastics company AVK.

-

Continuous Composites, Arkema partner to advance continuous-fiber 3D printing

The companies will combine Continuous Composites' CF3D process with Arkema's photocurable resins to develop and certify composite 3D-printing solutions.

-

Arkema to acquire Lambson

The company says Lambson’s range of photoinitiators for curing will complement its offering of Sartomer photocure resins and speed development in this market.

-

Consortium targets solutions for carbon fiber thermoplastic composite structures

The HAICoPAS project, led by Hexcel and Arkema, aims to optimize UD tape design and manufacture for aerospace and automotive composites.

-

Thermoplastic composites: Poised to step forward

The evolving role of thermoplastic materials and processes and their future in next-generation commercial aircraft.

-

Arkema Inc. builds U.S. PEKK production plant

The plant, located near Mobile, Alabama, will produce Kepstan PEKK materials targeted for carbon fiber-reinforced parts in next-generation aircraft.

-

Hexcel partners with Lavoisier Composites, Arkema

Hexcel has announced a partnership with Lavoisier Composites to upcycle composite by-products from the aerospace industry, and a joint R&D lab opening in partnership with Arkema.

-

Sartomer launches in-house electron beam labs for EB curing

The electron beam lab units are meant to enable customers to develop and test EB curing formulations on a small scale using Sartomer’s advanced liquid resin solutions.

-

JEC World 2019 preview: Sartomer and Arkema

Sartomer will feature specialty solutions that enable high-performance, low-VOC composites systems at JEC World 2019, at the Arkema booth.

-

Consortium works to develop biosourced composites from bamboo fiber

The BAMCO collaborative project aims to develop new biocomposites created from long bamboo fibres.

-

P2T process positioned for recycling

British company Prodrive Composites (Milton Keynes, UK) recently issued a press release about a process, called P2T (Primary to Tertiary), for manufacturing recyclable composite components that can satisfy future end-of-life requirements without any compromise in performance.

-

Study looks at composites in the furniture industry

AZL announces study aimed at understanding the selection process of furniture designers in order to bring composites to the market as an alternative to conventional materials.

-

Sustainable thermoplastics and additive manufacturing alliance forms in Colorado

Vartega, the Colorado Cleantech Industries Association and a group of industry and academic partners have founded an Advanced Materials and Additive Manufacturing Infrastructure Development and Education (AMIDE) Alliance.

-

Composites Pavilion at AIA 2018

New composite products for architecture/construction and student designs innovate how composites can be used.

-

New Products: April 2018

CW’s monthly roundup of new products for the composites industry.

-

New 3D printing filaments based on PEKK and PVDF now available

The new Kepstan PEKK and Kynar PVDF filaments are designed for 3D printing of highly technical parts requiring extreme performance.

-

FastRTM project demonstrates manufacturing of complex, net-shape composite parts

Automated production platform developed by a French industry consortium utilizes an epoxy resin system from Hexion Inc.

-

PEEK or PEKK in future TPC aerostructures?

Which is better for in-situ consolidated thermoplastic composite primary structures? Materials play a part as to whether a one-step or two-step process will prevail.

-

Hexcel and Arkema partner to develop aerospace thermoplastic composites

The strategic alliance aims to develop carbon fiber-reinforced thermoplastic tapes to produce lightweight parts for future generations of aircraft.

-

Automated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

-

JEC World 2016: Fully recyclable sailboat hull demonstrator

Arkema (Colombes, France), in addition to news of its collaboration with Polystrand (Englewood, CO, US), had as the centerpiece of its stand a complete carbon fiber sailboat hull made with the company’s trademarked Elium liquid thermoplastic resin.

-

JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

Wet compression molding

Automated process cuts cycle time and cost for CFRP parts with potential for 65% fiber volume via Dynamic Fluid Compression Molding variant.

-

CW Ideas in Action

Ideas are just ideas until someone does the hard work of putting them into action and seeing results. CW's editors, therefore, inaugurate an annual review of Ideas in Action, celebrating a handful of hot concepts that could make those who conceived them "household names."

-

The rise of HP-RTM

Decades of development have propelled it to prominence but its future demands industrial solutions for handling cost, complexity and process control.

-

Composites business does grow on trees

This advanced composites contractor welcomes down-to-earth opportunities to bring aerospace quality to fantasy foliage.

-

TAPAS 2: Next steps in thermoplastic aerostructures

The Netherland's-based Thermoplastic Affordable Primary Aircraft Structure (TAPAS) consortium's TAPAS 2 team builds on the successes of TAPAS 1, taking the next steps in aircraft thermoplastic composites architecture.

-

2014 JEC Europe Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

Wind blades: Progress and challenges

Despite double-digit wind energy industry growth, turbine blade manufacturers and materials suppliers acknowledge a pressing need to reduce costs and innovate.

-

Additives and modifiers: Matrix optimization

New and reengineered modifiers for thermosets and thermoplastics target previously elusive goals in composites processing and performance.

-

JEC Europe 2013 review

Snow in Paris slowed traffic to the show floor but did nothing to cool the enthusiasm of composites innovators in a broad range of markets.

-

JEC Europe 2013 new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the CT editorial staff's compilation of what was on display.

-

SAMPE Europe 2013/JEC Europe 2013 highlights

Held concurrently, these two seminal European composites events weathered a rare Parisian snowstorm to plumb the depth and breadth of the industry.

-

ACMA COMPOSITES 2013 review

Once again, cautious optimism, an abundance of revealing research and a parade of notable new products are ACMA convention keystones.

-

The evolution of infusion

As resin infusion continues to infiltrate composites, fabricators across the market spectrum drive materials and process developments in pursuit of process control.

-

Pultruded windows: Rising high?

New pultrudable glass fiber/resin formulations enable window manufacturers to break in to commercial architecture and build market share in residential construction.

-

2010 SAMPE Europe/JEC Paris Showcase

Record crowds and reignited technological development testified to the composite industry’s renewed health and the recent recession’s demise.

-

Composites 2010 Product Showcase

The ACMA’s Las Vegas exhibition reflected an industry in recovery.

-

CNTs ride a rising tide of nanotech optimism

Dr. Louis Pilato offers facts, figures and comment on the growing utility of carbon nanotechnologies in composites applications.

-

New infusion regime for superthick laminates

Innovative initiator chemistry yields long flow time, cure on demand and exotherm control for large, thick parts.

-

The key to CNTs: Functionalization

An emerging supply base is integrating carbon nanotubes into commercial products that enable composites manufacturers to optimize part performance.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

COMPOSITES+POLYCON 2009 Showcase

Despite the deepening recession, composites pros returned to the show in its new time slot to explore the wealth of products and services collected here.

-

JEC COMPOSITES 2007 Product Showcase - 7/1/2007

The annual Paris conclave showcases the global expansion of composites.

-

JEC Composites 2007 Product Showcase

This year’s Parisian exhibition provides key evidence of the composites industry’s unprecedented breadth and technical sophistication.

-

Rudder Gets New Twist With Composites

The U.S. Navy's specially contoured ship rudder commands composite construction.

-

SAMPE Europe/JEC Composites 2005

Advanced materials reap rewards, enter new arenas of application in annual Parisian showcase.