Additives and modifiers: Matrix optimization

New and reengineered modifiers for thermosets and thermoplastics target previously elusive goals in composites processing and performance.

In resin systems, additives adapt the base resins for particular applications and, thus, help differentiate products in the marketplace. Sometimes known as modifiers — a class distinction more descriptive of their function — they variously alter or fine-tune one or more of the system’s native processing or performance attributes.

Additive suppliers cite several trends in additive product development. One is sustainability. With an eye to increased regulatory scrutiny, many new developments have been stimulated by a desire for renewable content that is green (bio-derived) or recycled/recyclable. Another trend is a preference for reengineering. Salvatore Monte, president of Kenrich Petrochemicals Inc. (Bayonne, N.J.), says that to reduce regulatory exposure and product-development costs, many companies prefer to rework an existing product rather than develop a new one. He draws a parallel to the pharmaceuticals industry.

“Like drugs, additives are now subjected to a much more rigorous global registration process than just three decades ago — and the amount of time and toxicology study costs involved really require a ‘killer app’ that will justify the investment in a really new additive. So, blends, hybrids and new combinations and applications of existing additives will trump truly ‘new’ materials — unless a new additive is so disruptive that it cannot be held back because ever-increasing performance demands require its use.”

What’s clear is that both new and renewed resin modifiers are breaking new ground in process and part-performance optimization.

Flame retardants

Among reengineered additives, obvious examples are halogen-free flame retardants. Although they are harmless and beneficial in other uses, halogens (i.e., bromine, which, along with fluorine, chlorine, iodine and astatine, occupy Group VIIA of the periodic table) in some flame retardants that are used in plastics are now known to release toxic and corrosive gases when exposed to flame. Don Mills, sales director for fire retardants at Huber Engineered Materials (Atlanta, Ga.), isn’t alone in anticipating a continued reduction in their use. “As we evolve globally in seeking greener and safer solutions,” he predicts, “halogen-free products will be key to the future of the fire-retardant additive industry.” At the same time, he expects an increasing demand for products with greater flame retardant performance and lower smoke generation.

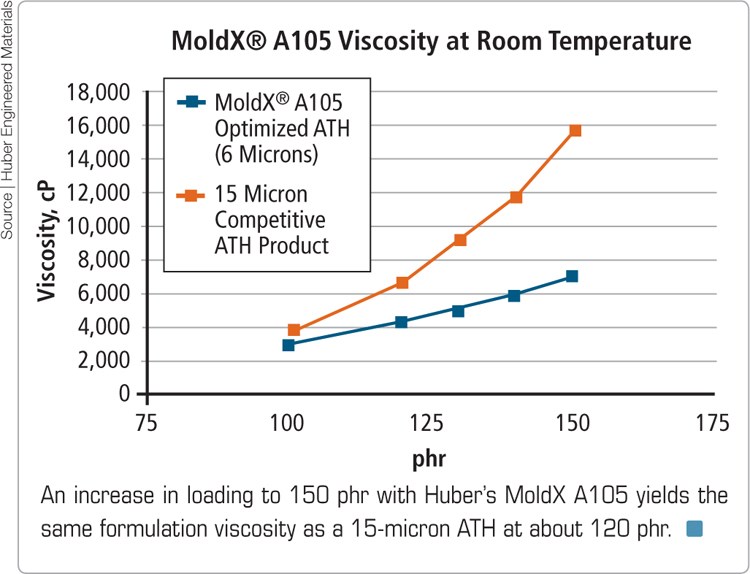

To meet this demand, suppliers are optimizing alumina trihydrate (ATH) products. “Many companies are trying to put more ATH into their flame-retardant compounds because many other flame retardants are too expensive or have environmental issues to overcome,” confirms Dan Mahlmeister, vice president at R.J. Marshall Co., The (Southfield, Mich.). In the past, there were practical limits to ATH content because the material raised compound viscosities so high they could not be processed. Recent developmental work has relaxed those limits.

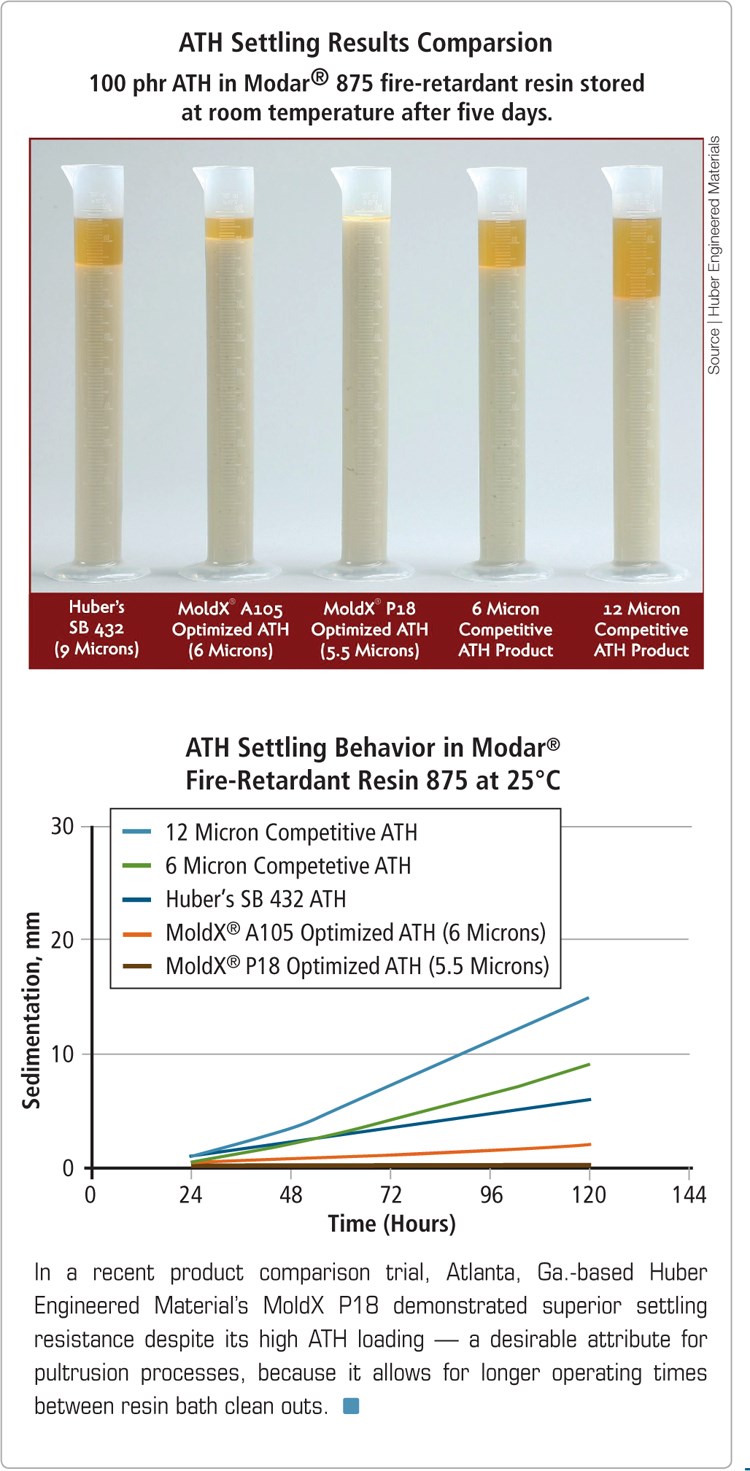

Huber recently introduced halogen-free MoldX-brand optimized ATH products for use in unsaturated polyester, vinyl ester and modified acrylic-based formulations. MoldX reportedly enables higher loadings without a change in viscosity, resulting in what is said to be outstanding mold flow. This enables a significant reduction of halogen-containing fire retardants without sacrificing flame retardant properties.

MoldX A100 for sheet molding compound (SMC), bulk molding compound (BMC) and hand layup applications allows load levels from 250 per hundred parts resin (phr) to as high as 400 phr. It is suitable for halogen-free product formulations that require significant smoke suppression, and its low viscosity reportedly allows molders to process it on SMC machines and in BMC mixers at loading levels not previously thought possible. And, Huber says, its flow properties make it suitable for molding large, intricate parts.

Two other MoldX grades are targeted to pultrusion, resin infusion and wet mat applications. MoldX A105’s fine particle size makes it useful in any process that is sensitive to particles coarser than 45 microns in parts with a glass content less than 55 percent. It’s particularly suitable when fiberglass mat acts as a filter to prevent the free flow of particles suspended in the resin. Its low viscosity allows formulators to use a higher loading than is typical. For glass content greater than 55 percent, Huber offers MoldX P18 for pultrusion, resin infusion, cured-in-place pipe (CIPP) and vacuum bag molding of fiberglass-reinforced polyester. P18’s particle size distribution tops out at <18 microns, which has been shown to provide excellent processing at high fiber-to-resin ratios. Lacking coarse particles, it reportedly flows readily throughout the reinforcement. As a result, a pultruder, for example, can use a lower pull force and achieve line speeds that are not possible with conventional ATH.

For similar reasons and with similar results, R.J. Marshall has added optimized ATH products to its Maxfil line, particularly for BMC and SMC applications. Careful management of particle-size distribution in these specialty grades allows higher loadings, which increases flame retardancy without increasing resin viscosity. Three ATH grades feature, respectively, maximum 5-micron, 10-micron and 45-micron particle sizes. The company also has added blends of ATH and calcium carbonate for applications where flame retardance and smoke suppression are not as critical, such as BMC/SMC sprayup of wall panels for bathrooms and pultruded pipe for oil platforms.

For thermoplastic composites, Clariant Plastics & Coatings USA (Muttenz, Switzerland, and Charlotte, N.C.) has announced two developmental flame retardants for its Exolit OP line. The first is Grade OP 1400, designed for glass-reinforced nylon 6 and 6/6 used in electric/electronic, transportation and appliance applications. Like its predecessors, OP 1312 and 1314, it is a blend of organic aluminum phosphinate and synergists. However, this semicommercial product also contains a new substance currently under registration or evaluation in the U.S. Environmental Protection Agency’s Toxic Substance Control Act inventory and similar inventories in other countries. OP 1400 offers low density, good mechanicals and high comparative tracking index (CTI) values — the CTI integrates standard industry test methods UL 94, glow wire index test (GWIT), Needle Test, and limiting oxygen index (LOI). Functionally, OP 1400 enhances thermal stability, making it suitable for use at high processing temperatures and in formulations that are injection molded into complex cavities, even in hot and humid shop environments. In reinforced nylons, all three grades (1400, 1312 and 1314) reportedly achieve UL 94 V-O classification (burning stops within 10 seconds) at thicknesses as low as 0.4 mm/0.0157 inch.

The second new retardant, Grade OP 1260 (a test product), is a synergistic blend that achieves UL 94 V-O at 0.8-mm/0.0314-inch thickness, with only 18 percent loading vs. 20 percent loading for its predecessor, OP 1240. It also enhances the melt flow and mechanicals of glass-reinforced thermoplastic polyester PET/PBT blends. Compared to reinforced PBT and PBT blends that are combined with a brominated flame retardant, ATH blends that contain either OP 1260 or 1240 have lower densities and much higher CTI values. Formulations that contain OP 1260 surpass the halogenated flame-retardant formulation in elongation at break and also have near-equivalent notched Izod impact strength.

Nabaltec AG’s (Schwandorf, Germany) viscosity-optimized ATH filler is designed to achieve the highest performance possible in resin transfer molding (RTM) applications. Apyral 44 ATH is characterized as a fine-particle product that will not increase resin viscosity in fast infusion processes. It features optimized filtration behavior, results in good part surface quality and contributes good flame retardance. High loadings are possible, and Nabaltec says it has shown that this product improves flow, compared to other ground hydrates in unsaturated polyester resin composites.

Cure management

The movement to halogen-free flame suppressors has been mirrored by the advent of cure accelerators that contain alternatives to carcinogenic cobalt components. Although the move to cobalt-free accelerators for the curing of unsaturated polyester and vinyl ester resins is centered in Europe, the “winds are blowing this trend to North America,” says Mike Wells, senior applications engineer at Arkema Inc. (King of Prussia, Pa.).

The OM Group (OMG, Cleveland, Ohio), for example, continues to expand its Borchi Oxy Cure line, which is based on patented iron ligand technology as an alternative to cobalt in the curing of unsaturated polyesters. Included is a developmental product, WXP-126, a solution of a highly active iron complex called FeLT.

Kenrich Petrochemicals is converting exothermic peroxide-cured unsaturated polyester composites into bubble-free endothermic systems (absent cobalt accelerators) by using elevated temperature (40°C/104°F) as the “accelerant” in combination with hybrid titanate coupling agents, such as the company’s Ken-React CP-XP1 (see “Coupling agents,” later).

Akzo Nobel Polymer Chemistry (Amersfoort, The Netherlands, and Chicago, Ill.) has extended its portfolio of 100 percent cobalt-free curing solutions with the launch of its second-generation Nouryact accelerators. Based primarily on iron, the new “eco-premium” accelerators are said to work in a wide range of temperatures and reportedly have a low impact on end-product coloration. The company claims they readily replace existing cobalt-based accelerators and, in some cases, enable cure behavior that is not achievable in conventional systems.

In contrast, Pergan GmbH’s (Bocholt, Germany) new Pergaquick CP is a reportedly nonhazardous cobalt polymer accelerator product line, an alternative to the cobalt octoate (cobalt 2-ethylhexanoate) now classified as a carcinogen. Pergan says the new accelerators bind the cobalt into a high-molecular-weight matrix that is said to “decrease its bioavailability yet safeguard its curing performance.” Moreover, cobalt polymer is reportedly exempt from registration, according to REACH, the European chemical regulatory agency.

The increasing need to control resin pot life and the timing of cure initiation prompted the development of Arkema’s Luperox IS Series additives, which are specifically aimed at vacuum infusion and RTM of extremely thick vinyl ester and unsaturated polyester resin composites. Said to be particularly effective in closed molding processes (pultrusion, vacuum infusion, RTM and compression molding of SMC and BMC), the additive packages contain Luperox IS 300, a blend of peroxide and BlocBuilder RC-50, a nitroxide-mediated reactivity controller. The latter prevents the reaction between unsaturated vinyl/polyester resins and organic peroxides at or below predetermined low temperatures. At temperatures above 60°C/140°F, however, RC-50 will “unblock” and allow the peroxide to initiate the reaction. It has been shown to extend the pot life of prereacted resins and can enhance the stability of faster-reacting systems.

Cost vs. performance

No less evident is a continued emphasis on improving the cost/performance quotient of all additives. Arkema’s Wells speaks for many when he says that, generally, the green driver continues to be bigger in Europe and Canada; the big driver in the U.S. is cost.

Stephan Sprenger, senior market development manager for composites and lightweight construction consumer specialties at Evonik Corporation (Geesthacht, Germany), cites two cost vs. performance trends: reducing the cost of wind turbine manufacturing, especially the blades, while increasing performance (e.g., fatigue); and reducing costs and shortening production cycles to three to five minutes as required by the automotive sector, which is swiftly moving to composites. Evonik Hanse, formed in 2011 when Evonik Industries AG (Essen, Germany) acquired Hanse Chemie GmbH and Nanoresins AG, addresses these trends with several products. Nanopox modifiers, such as its F-Series colloidal silica sols, have been shown to improve fatigue performance in thermoset composites by up to five times. Abipox tackifiers reduce layup time in the mold (e.g., in large wind blade tools), and internal mold releases from the company’s family of Tegomer/Tegopren organosiloxanes eliminate the need for external agents and their application and, thus, speed the production cycle.

Still, a strong thrust in the cost arena is the use of fillers and extenders to minimize the impact of resin cost on part cost. For the fire retardants business, Huber’s Mills sees continued efforts to increase mineral extenders’ load levels. “There will be interest in utilizing extenders that contain recycled or green content,” he says, “although the low cost of conventionally milled extenders will limit usage due to the high cost of reclaiming materials.”

Styrene suppression

Arkema’s Wells also cites a big push in North America away from styrene-based resins and additives, partially because late in 2011 the U.S. Department of Health and Human Services classified styrene as a suspected carcinogen (see "Styrene: Issues and Implications," and "The Stryrene puzzle" “Editor's Picks," at top right). One alternative, he says, is acrylic resin, but he concedes that the cost of transitioning to acrylics is an issue, not least because they’re more expensive than their styrene-based counterparts. Still, Wells sees acrylic resins as capable of finding a price/performance niche between unsaturated polyester and vinyl ester resins.

Arkema formulates acrylic-based modifiers and acrylic-based additives, and some of its recent additive developments are geared to further that aim. For example, new Luperox LP dilauroyl organic peroxide is a low-melting solids product that demonstrates excellent solubility in acrylic composites. Another such product is PNP25, an all-aliphatic, tertiary-butyl acid peroxide based on naturally occurring materials, as opposed to conventional methyl ethyl ketone peroxide (MEKP). PNP25 is said to be well suited to acrylic composites and is promotable without cobalt accelerators.

Elsewhere, BYK USA’s (Wesel, Germany) new green BYK-S 760 styrene emission reducer combines waxes with polar components (more than 85 percent renewable raw material content) and is reportedly highly effective in reducing the monostyrene emissions that are typical of polyesters and vinyl esters at recommended load levels of 0.3 to 1.0 percent. The additive, however, is said to have no negative influence on interlaminar adhesion because more than 70 percent of its ingredients contain unsaturated groups, which react with the resin during polymerization.

Coupling agents

Central to the sustainability trend are bio-based resins. Kenrich Petrochemical’s Monte sees new interfacial coupling technologies as the keys to bringing these materials up to very high performance levels. “For decades, I have aimed to teach the more efficient use of raw material through titanium chemistry,” he says, noting that today the resulting organometallics, in liquid, powder and pellet form, can contribute significantly to composite mechanicals.

Kenrich has several developments underway involving its Ken-React titanate and zirconate coupling agents. “Since our organometallics are designed to form 1.5-nanometer atomic monolayers, which means they provide organo-functionality on any inorganic or organic surface via proton coordination absent the need for water of condensation, we have an enabling nanotechnology that allows for optimal functionalization of larger nanoparticulates, such as montmorillonite clay. Sometimes resin producers and compounders make the mistake of exfoliating nanoparticulate with low-cost ammonium quats.” This provides greater Angstrom platelet separation, but leaves up to 35 percent ammonium quat chemistry on the nanoclay surface, which makes the interface incompatible with some polymers. “We get the job done with one-tenth the amount of a titanate-zirconate hybrid quat, which is completely compatible with the full range of thermoplastic and thermoset polymers.”

Kenrich test data reportedly demonstrates the efficacy of titanates and zirconates in unfilled and filled polymers and indicates that they could be better coupling agents than silanes for glass, aramid and carbon fiber and nanoreinforcements. These findings have been substantiated in commercial applications, where the addition of a titanate coupling agent reduced the severity of cracking along weld lines where there is little glass content. There was a significant decrease in barrel temperatures from as high as 304°C/580°F, without a coupling agent, to as low as 188°F/370°F with the titanate, and there was a reduction of about four seconds in cure time over other coupling agents. Similar findings have been reported in thermoset composites.

Surface quality and durability

Suppliers cite a definite upward trend in part surface quality (driven in part by the auto industry’s demand for Class A body panels) and maintenance of part appearance over its useful life.

Sprenger says grades from Evonik’s Nanopox line have successfully enhanced the scratch resistance of unpainted epoxy composite parts, where the aim is to display the texture of woven carbon fiber. Similarly, antiscratch additives have been used in unsaturated polyester composites, such as subway car wall panels and in glass-fiber-reinforced thermoplastic composite door panels. The technology is based on Evonik’s Tegomer/Tegopren organomodified siloxanes (OMS), which serve as multifunctional additives in thermoplastic and thermoset composite formulations. In glass-reinforced nylons, polybutylene terephthalate (PBT) and PC, certain grades (e.g., H-Si 6440P and AntiScratch 200) have long demonstrated outstanding scratch and mar resistance.

Newer Tegomer/Tegopren OMS grades have been shown to provide a significant advantage as defoamers, particularly in glass-reinforced epoxies and unsaturated polyesters. They improve fiber wet out, and as a result, the fiber retains its key bulk properties (i.e., hardness, transparency, inertness) and will not print-through to the surface, resulting in a smoother surface appearance.

In unsaturated polyesters, grades like Tegomer M-Si 2650 improve scratch resistance and reduce sedimentation. In epoxy composites, they also serve as internal release agents and dispersion aids for fillers. For example, Tegomer M-Si 2650 added at 0.3 percent to epoxy resin systems forms a separating film that enables easy demolding yet does not diminish paintability.

An improved surface finish is one benefit of Huber’s new Hubercarb W4 ground calcium carbonate. This cost-effective extender, a uniquely soft and low-silica micritic limestone ore, mills to a more spherical shape than conventional marble sources, which grind to rhombohedral forms. W4 minimizes glass fiber breakage during processing and molding because its rounder shape and broad particle size distribution not only enables maximum particle packing and, therefore, higher mineral loadings but it also keeps the viscosity low and reduces part shrinkage in most molding processes.

Wacker Chemical Corporation (München, Germany) has added two new low-profile additives (LPAs) for room-temperature processes to its Vinnapas range of polyvinyl acetate (PVAc) solid resins for optimized nonshrink surfaces. They have been shown to reduce the shrinkage of unsaturated polyesters to less than 0.05 percent, yielding a Class A surface. The first, Vinnapas LL 8588, a novel polymer architecture composed of polyvinyl acetate and polystyrene segments, also ensures that the finished product has low water uptake. Developed for semiautomated, low-emissions infusion processes, it reportedly promotes rapid infusion and is suitable for complex composite parts in automotive or boat and yacht applications. The second, Vinnapas LL 8251, is a copolymer of vinyl acetate and crotonic acid. Its viscosity is similar to that of saturated polyesters, so it is said to be easy to process, even at high fiber and filler contents. Beyond typical applications in the automotive sector, it has potential for use in composites for construction (windows, doors, industrial profiles and railings).

For its part, Arkema is pressing commercial development of two nanoreinforcements, says Michel Glotin, director of materials science. The first is Graphistrength C S1-25 multiwall carbon nanotube liquid masterbatch (20 percent MWCNTs) designed for use as a modifier in thermoset-based composites. It is still in a relatively nascent stage, so the company has been selling small quantities primarily for high-performance epoxy materials. Glotin reports that commercial applications so far include hockey sticks, bicycle wheels and baseball bats, where the masterbatch serves primarily to improve modulus and resist crack propagation. The second, the Nanostrength acrylic block copolymer family, is in an earlier stage of development as a modifier for epoxies. It features three blocks of linear molecular chains covalently bonded to one another. Nanostrength is blended with a polymer that is compatible with one of the three blocks, so it disperses easily and imposes a structural organization on the host matrix that has been shown to impart impact strength, high rigidity and transparency. In hockey sticks made of epoxy composites, Nanostrength demonstrates high resistance to crack propagation yet retains or increases the final glass transition temperature (Tg) of the cured system at 10 percent loading.

Related Content

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MoreRead Next

Styrene: Issues and implications

The facts (such as they are) behind the furor surrounding this vital crosslinking chemical’s listing in the 12th RoC.

Read MoreFiber sizings: Coupling agent companions

Although the primary function of sizing is to protect the fiber from abrasion damage by acting as a dry lubricant during processing functions such as weaving, sizing expert Andy Brink, business development manager at Michelman SARL (Cincinnati, Ohio), says sizings on reinforcements used in composites also contribute to adhesion at the fiber/resin interface.

Read MoreThe styrene puzzle

CT editor-in-chief outlines two major challenges posed by the recent listing of styrene in the U.S. National Toxicology Program's 12th Report on Carcinogens.

Read More

.jpg;width=860)

.jpg;maxWidth=300;quality=90)