Workforce Development

TRB Lightweight Structures partners with University of Bristol to broaden PFA offerings

Knowledge Transfer Partnership project aims to develop novel and improved PFA resin formulations for composite applications.

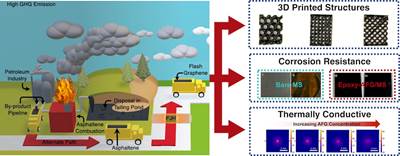

Read MoreRice University turns asphaltene into graphene for composites

University scientists use novel flash Joule heating process to convert crude oil byproduct into graphene, to then be mixed with composites for thermal, anti-corrosion and 3D-printing applications.

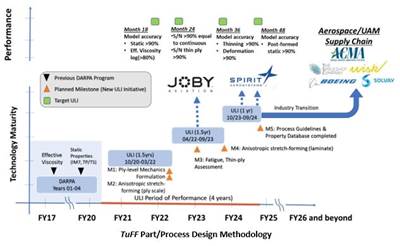

Read MoreUD’s Center for Composite Materials hosts NASA University Leadership Initiative

October meeting of industry, government and academic accentuates the University of Delaware’s study of research and technology barriers in UAM using its new class of composite materials, TuFF.

Read MoreUniversity of Maine unveils 100% bio-based 3D-printed home

BioHome3D, made of wood fibers and bioresins and entirely 3D printed, highlights Maine’s effort to address the need for more affordable housing.

Read MoreThe importance of resin mixing procedures in the composites shop

What is considered to be common knowledge when storing, handling, weighing, mixing and deploying epoxy resins and adhesives has brought to light the need for tighter control, improved practices.

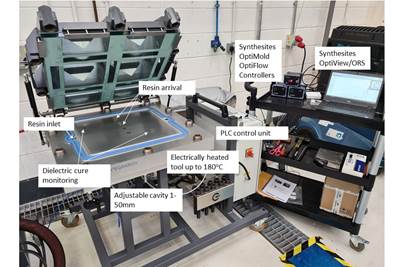

Read MoreUlster University, Synthesites advance intelligent cure monitoring

Research collaboration to enable active control and optimization for RTM process for composite structures manufacture.

Read MoreAnisoprint R&D team begins 3D printing center at Jacobs University Bremen

Established research environment to comprehensively upgrade CFC technology, explore new composites methods, formulations and designs.

Read More9T Labs, Purdue University to advance composites use in structural aerospace applications

Partnership defines new standard of accessibility to produce 3D-printed structural composite parts as easily as metal alternatives via Additive Fusion Technology, workflow tools.

Read MoreUniversity of Southern Queensland project to create new class of epoxy resins

Project leader Dr. Siqi Huo awarded more than $421,000 through the Australian Research Council to create single-component epoxy resins with improved storage stability, fire retardancy, mechanical properties.

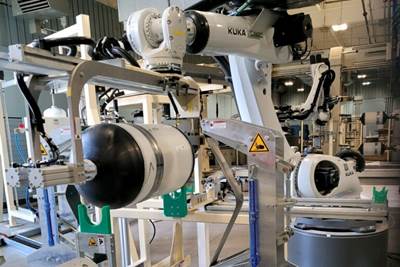

Read MoreAutomated filament winding system increases throughput, reduces manual labor for pressurized well tank production

For its new line of composite well water tanks, Amtrol worked with Roth Composite Machinery on an automated process for faster, more easily tracked production.

Watch