9T Labs, Purdue University to advance composites use in structural aerospace applications

Partnership defines new standard of accessibility to produce 3D-printed structural composite parts as easily as metal alternatives via Additive Fusion Technology, workflow tools.

9T Labs AG (Zürich, Switzerland), experts in digital, automated and cost-competitive serial production of continuous fiber components, has announced the company’s new collaboration with Purdue University (West Lafayette, Ind., U.S.) to research and test the potential of manufacturing structural aerospace composite applications at scale with 9T Labs’ Additive Fusion Technology (AFT).

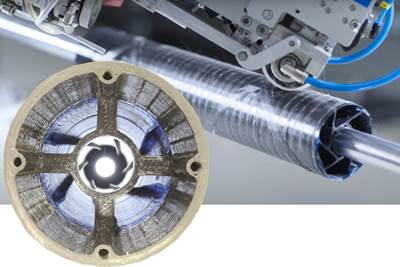

This partnership with Purdue is reported to be a first-of-its-kind collaboration for 9T Labs in the U.S. The hybrid solution, which combines high-resolution additive manufacturing (AM) with the speed of bulk molding compound (BMC) overmolding to automate manufacturing, offers a cost-competitive option versus the traditional production of aluminum aerospace parts, according to the company. 9T Labs’ approach to continuous fiber 3D-printed preform parts has shown potential in the transportation, medical and robotics industries, among others.

Purdue University’s Composite Manufacturing and Simulation Center (CMSC) provides the necessary tools and resources to analyze, simulate and test the performance of composites. 9T Labs and Purdue worked collaboratively to develop the application workflow to efficiently engineer and manufacture high-performance parts using BMC chips and continuous fiber 3D-printed preforms. Initial testing shows that customized continuous fiber hybrid parts can be digitally designed, 3D printed and co-molded with BMC materials, ensuring performance at only a fraction of the usual cost of continuous fiber materials.

“This new partnership with Purdue is an additional step toward building a consortium of partners from academia and industry to penetrate the market.”

“Traditional composites manufacturing is expensive, wasteful and limited in its geometric freedom, particularly for small-sized applications,” Yannick Willemin, head of marketing and business development, 9T Labs, says. “We are defining a new composites manufacturing standard that allows us to produce structural composite parts as easily as metal parts. Our new partnership with Purdue University is a meaningful step toward making this technology more broadly available and accessible within the next 12-18 months.”

The origins of this partnership trace back to when 9T Labs’ CEO and co-founder, Martin Eichenhofer, learned of Dr. R. Byron Pipes, a John L. Bray distinguished professor of engineering, and his work on composites during his PhD studies. “When I heard about the new Composite Manufacturing and Simulation Center led by Dr. Byron Pipes, I reached out to him to discuss what we were doing at 9T Labs,” Eichenhofer explains. “His curiosity was piqued and we discovered an opportunity to work together on advanced thermoplastic composites. It is an honor to work with such a distinguished person and such a great team in the composites field.”

According to Dr. Pipes, Purdue has “chosen to collaborate with 9T Labs because we believe that their development of AFT and their novel hybrid approach is the future of the composites manufacturing industry.”

Beyond the practical applications and potential that the AFT hybrid solution brings to multiple industries, 9T Labs says there are strong economic and sustainability benefits to using this technology. The combination of zero-waste approach, the possibility to recycle thermoplastics and the positive impact on part performance being at least 50% lighter than the metal benchmarks makes AFT an attractive standard of manufacturing. AFT also enhances the strength performance of molded components without compromising manufacturing rates.

“9T Labs is at the forefront of a new field of composites manufacturing that has real-world implications for structural and processing simulation, material compositions and characterization, experimental testing and application engineering,” Eichenhofer adds. “This new partnership with Purdue is an additional step toward building a consortium of partners from academia and industry to penetrate the market and accelerate the adoption of AFT and composite materials for a broad application field.”

Learn more about the company’s technologies, recent collaborations and more at the 9T Labs CAMX booth.

Related Content

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreReinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

Read MoreIndustrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MorePlant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MoreRead Next

The evolution of additive composites

Defining additive composites manufacturing and how its merge with conventional processes is providing new solutions and a path forward.

Read MoreSetforge to serially produce composite parts using 9T Labs technology

The former metal component forger seeks the disruptive manufacture of high-performance CFRTP parts using 9T Labs’ Red Series Additive Fusion Solution platform for current and new markets.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More