UD’s Center for Composite Materials hosts NASA University Leadership Initiative

October meeting of industry, government and academic accentuates the University of Delaware’s study of research and technology barriers in UAM using its new class of composite materials, TuFF.

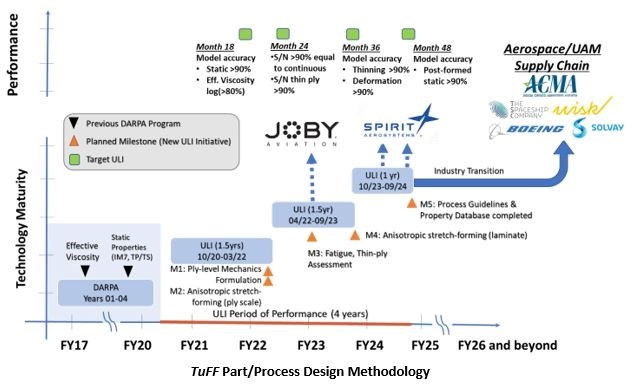

Project description outlining the TuFF technology maturation timeline. Photo Credit: University of Delaware Center for Composites Materials

The University of Delaware’s Center for Composite Materials (UD-CCM, Newark, U.S.) hosted the Second Annual Review of the NASA University Leadership Initiative (ULI) Composite Manufacturing Technologies for Aerospace Performance at Automotive Production Rates project.

Led by a team from UD, this $5.8 million NASA-sponsored research award is addressing basic research and technology barriers in urban air mobility (UAM). The project is also focused on education and workforce training needs through a focus on opportunities for undergraduate interns, graduate research in composites manufacturing and collaborative training opportunities with the program’s HBCU and industry partners.

The research centers on CCM’s patented process for creating a new class of materials known as TuFF (Tailorable universal Feedstock for Forming). Composed of highly aligned short carbon fiber with a thermoplastic matrix, this material is said to enable maximum weight savings, extended electric vertical takeoff and landing (eVTOL) range and reduced manufacturing costs (learn more about the material, “University of Delaware TuFF composite material shows high potential for UAM”). The goal is to develop physics-based simulations tools for modeling different processes in the manufacturing process, then incorporating these models into software suited for part design and manufacturing using TuFF.

The meeting, held on Oct. 13, 2022, hosted nearly 200 virtual and more than 50 in-person attendees from NASA and other government agencies, industry and academia. The meeting featured technical presentations, an hour-long Q&A session and lab tours and demonstrations at the CCM and the CCM Applications Technology Transfer Laboratory.

CCM-affiliated speakers included Shridhar Yarlagadda, CCM assistant director for research and associate professor in the Department of Electrical and Computer Engineering; postdoc Nithin Parambil, doctoral student Brandon Chen; research associate Pavel Simacek; composites process development specialist Tom Cender; and senior scientist John Tierney.

“In addition to the research and technical progress, we are pleased with the success of our education and outreach activities with Southern University,” Jack Gillespie, professor and director of CCM, notes. “Overall, over 500 K-12 students with approximately 60% from underrepresented groups were involved in NASA ULI-sponsored activities.”

Related Content

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.