NDT

Machine, equipment investment strengthens Ruckus Composites’ research, innovation

CNC services expansion, universal testing machines and advanced inspection enable Ruckus to delve deeper into the study and evaluation of carbon fiber damage, as well as nondestructive and destructive testing.

Read MoreUTComp authors bulletin on fitness-for-service assessment of FRP

Welding Research Council (WRC) Bulletin 601 provides technical background and validation for quantitative nondestructive testing methodology for FRP composite equipment.

Read MoreLoop Technology develops robotic arm for wing box inspection

Part of an R&D project with Spirit AeroSystems, the seven-axis Bravura robotic arm automates inspection and sealing within small spaces like aircraft wing boxes.

WatchEvident wind blade inspection system automates nondestructive ultrasonic testing

An autonomous, cobot-mounted inspection system combines Industry 4.0 with established ultrasonic technology to rapidly provide repeatable, accurate data and improve overall efficiency.

WatchMoviTHERM opens in-house NDT lab

New inspection techniques, excitation sources and infrared cameras enhance feasibility study capabilities for customers in the composites industry.

Read MoreCAMX 2022 exhibit preview: Innerspec Technologies

Taurus and Camus 3D ultrasonic inspection systems provide automated and semi-automated solutions for composite aerospace components.

Read MoreTwenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

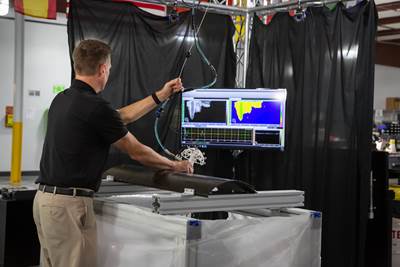

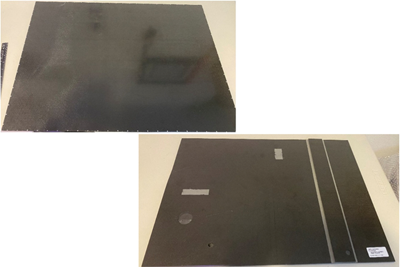

WatchDolphicam2 NDT system identifies flaws in CFRP panel in one setup

A second benchmark study on a CFRP NDI Proficiency specimen 1A assesses NDT equipment and personnel, successfully characterizes all flaws in panel.

Read MoreNCMS report demonstrates thermography innovations for enhanced NDI capabilities

Technology brief highlights how thermographic signal reconstruction (TSR) has enhanced the readiness of aircraft in less time and at lower cost, with potential for use inspecting composites and metals.

Read MoreDolphitech capability study benchmarks dolphicam2 NDT platform

A CFRP panel was manufactured to the specification of an FAA NDI Proficiency specimen 2A, representative of composite laminates found on commercial aircraft.

Read More