NDT

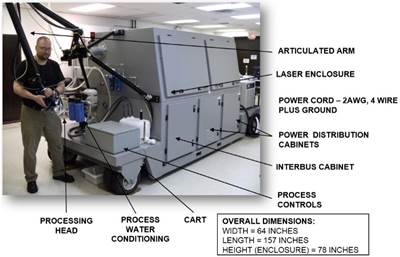

Laser bondline inspection becomes reality

One of the Holy Grails of composites manufacturing has been reliable verification of adhesive bondline strength integrity. A technology that does just that has arrived.

Read MoreNCC sensor technology unlocks digital potential for liquid resin processes

Research and testing of dielectric sensors performed by the NCC, Meggitt and Cranfield University accurately captures resin infusion data, shows promise for composites manufacturing.

Read MoreHow ultrasonic testing can find flaws in composite materials

As composite applications expand, so does the demand for more capable inspection systems. Ultrasound has proven to be effective when it comes to in-depth, sophisticated testing.

Read MoreDolphitech releases MxTTU digital scanning solution

In-service inspection capabilities are made more robust, flexible and portable, with the ability to precisely diagnose a larger inspection area and inspects materials that hinder sound propagation.

Read MoreNondestructive testing technologies handle demanding inspection environments

Zetec phased array ultrasonic testing (PAUT) inspection products Emerald and Topaz feature real-time TFM capabilities, more detailed inspection results and improved performance.

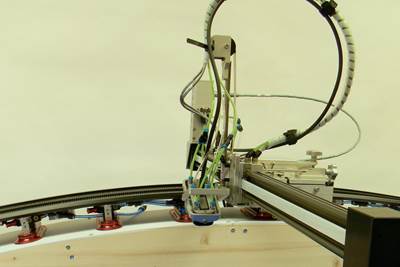

Read MoreDesigning for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

Read MoreCAMX 2021 Show Daily highlights composite technology innovations

As the CAMX media sponsor, CompositesWorld reported on several new or improved developments on display, from CAMX Award and ACE Award winners, to the keynote speaker and interesting technologies.

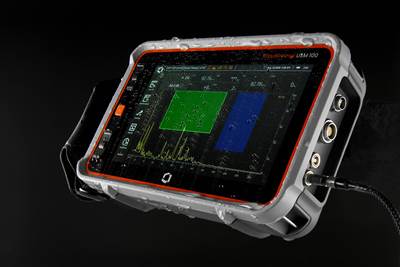

Read MoreWaygate Technologies launches fully connected ultrasonic flaw detector

The customizable, handheld Krautkrämer USM 100 sets new standards in ergonomics, connectivity and ruggedness for composites inspection requirements, such as complex wave propagation and high attenuation.

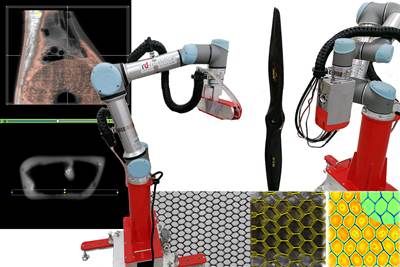

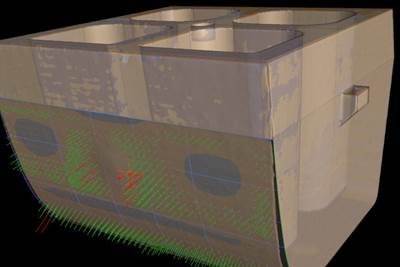

Read MoreRobotic computed tomography – removing NDT barriers for composites

Radalytica uses collaborative robots, ultra-sensitive X-ray photon detectors and the ability to combine CT with ultrasound, surface profiling and other inspection methods to optimize composites part quality, production and reduce cost.

WatchVolume Graphics CT software update detects and corrects design flaws and manufacturability issues

Version update for data analysis software suite improves usability, speed and accuracy of non-destructive testing, analysis and geometry repair of parts from injection molding, casting or 3D printing.

Read More