Curing

University of Bristol, NCC develop novel composite materials to assess performance in space

In-house developed matrices reinforced with carbon fiber will spend six months attached to the ISS to better understand and improve their functionality in extreme space conditions.

Read MoreLEWCO presents enhanced-duty, vacuum-assisted composite curing oven

The composite oven, recently delivered to a U.S. military base, reaches a maximum temperature of 500°F and is used to cure vacuum-bagged composite aircraft parts.

Read MorePorosity, voids and bridging in prepreg autoclave and vacuum bag-only laminates

Consideration of materials, methods and systems explores ways to reduce potential surface porosity, voids, resin-rich areas, bridging and other flaws in composite laminates.

Read MoreEpisode 38: Alan Hiken, Kane Robotics

Alan Hiken, COO of Kane Robotics, talks about historic, current and future composites use in aircraft fuselage structures and the role of automation in next-gen manufacturing environments.

ListenEasy Composites appointed as exclusive U.K. distributor of Eco-Technilin natural fiber reinforcements

Eco-Technilin natural fiber product range offers woven, nonwoven, UD and prepreg reinforcement options that are more sustainable, affordable alternatives to traditional reinforcements like glass fiber.

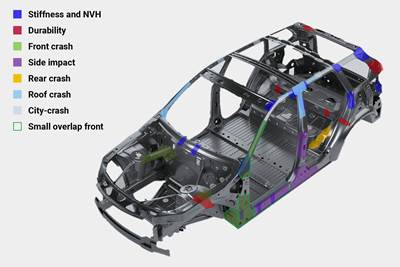

Read MoreComposites as auto-body reinforcements

Hybrid structural-reinforcement technology expands options, gains applications, markets.

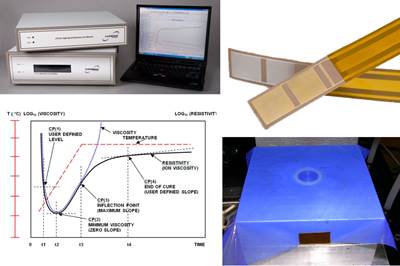

Read MoreCombining AC and DC dielectric measurements for cure monitoring of composites

Lambient Technologies advances dielectric analysis (DEA) for more reliable, affordable composites manufacturing.

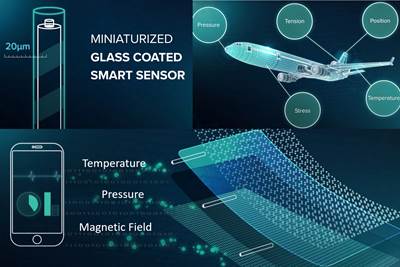

Read MoreContactless measurement of temperature, pressure in composites

Magnetic microwires enable contactless measurement of temperature and pressure during cure and in service.

WatchTPS ships Gruenberg vertical conveyor oven, meets specific customer needs

Stainless steel internal chamber, operating temperature of 270ºF and an installed high-volume, 6135 CFM horizontal airflow system.

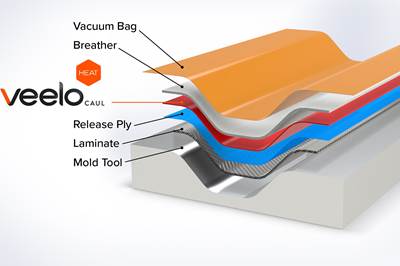

Read MoreVeeloHEAT Caul enables in-situ hot debulking capabilities

Built on existing debulk bagging procedures, Veelo Technologies’ debulking solution can take place at the tool during layup, reducing costs and improving throughput.

Read More