Inside Manufacturing

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

Stewart Mitchell

Contributor writer

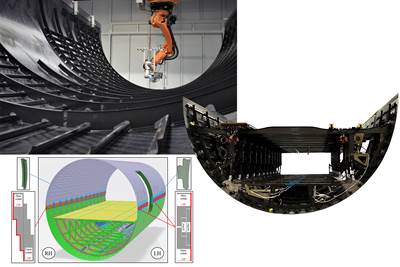

Optimizing AFP for complex-cored CFRP fuselage

Automated process cuts emissions, waste and cost for lightweight RACER helicopter side shells.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

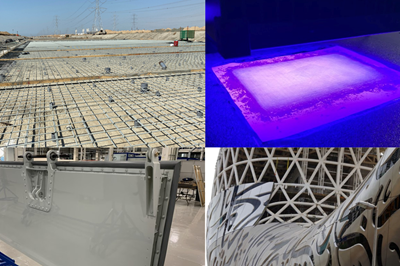

Read MoreComposites enable epic interior for Museum of the Future

For this one-of-a-kind lobby, AFI pioneered digital, reconfigurable molds to achieve organic-shaped, multifunctional panels and stairwell cladding.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

Read MoreComposite rotary milking platform evolves via process innovations

Infusion and LRTM-based processes and design enabled Waikato Milking Systems to bring a lighter, less labor-intensive platform to the global dairy market.

Read MoreEasy-to-use kits enable infield repair of composite structures

Portable kit enables patch repairs using UV-cure glass fiber/vinyl ester or room-temp stored carbon fiber/epoxy prepregs and battery-powered curing equipment.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Ginger Gardiner

Senior Technical Editor, CompositesWorld

Braided preforms and resin infusion for next-generation aerocomposites

Spintech shows significant cost and labor savings using its Smart Tooling, dry fiber preforms and RTM/VARTM technology on aircraft wing and inlet duct demonstrators.

Read MoreLarge composite covers protect a lot of water

A massive concrete water storage facility in Bogotá, Colombia, gets a much-needed makeover with the resin transfer molding of 840 large composite domes that keep the water potable.

Read MoreAdvancing the OOA infused wing box

MTorres integrates lower cover, front and rear spars into unitized flying demonstrator using one-shot, low-cost, portable production.

Read MoreBuilding the Museum of the Future

FR composite panels provide structure, sealing and iconic facade for pioneering architecture in Dubai.

Read MoreC-FREX exoskeleton depends on CFRP for unpowered movement

C-FREX uses a novel design and CFRP to overcome the heaviness and weakness of metallic exoskeletons.

Read MoreHigh-rate, automated aerospace RTM line delivers next-gen spoilers

At Spirit AeroSystem’s Prestwick facility in Scotland, a glimpse of the future of aerocomposites manufacturing in a resin transfer molding line for A320 spoilers.

Read MoreCompositesWorld's top ten "Inside Manufacturing" articles

CW’s Inside Manufacturing column dives into the processes, materials, technologies, and applications related to composites manufacturing. Take a look at our top ten most popular pieces from this column and see what interests you the most.

Cara Ready

Content Marketer, Gardner Business Media, Inc.

Compression RTM for production of future aerostructures

Automated preforming and 5-min resin infiltration show a way forward for lower-cost CFRP primary structures.

Read MoreOvermolded hybrid parts open new composites markets

A process that combines continuous carbon fiber-reinforced PAEK with chopped fiber/PEEK overmolding is making inroads in the aerospace market. Parts that previously could not be produced cost-effectively from composites can now be made at less cost than their metal counterparts.

Read MoreAutomated joining of hybrid metal-thermoplastic composite structures

The FlexHyJoin production cell combines surface structuring, induction and laser joining and NDT for automotive mass production.

Read MoreFilament wound utility poles offer design flexibility

In Turkey, a utility pole manufacturer combines filament winding, automation, glass and carbon fiber composites to expand its product line.

Read MoreComposites design and process engineering form next-generation truck body panels

Glass fiber/foam preform technology is key to the all-composite refrigerated truck body panels.

Read MoreSpar forming simplified

Adapting its Automated Stiffener Forming (ASF) technology to build spars directly in female molds, Northrop Grumman Innovation Systems anticipates dramatic drops in cycle time and manufacturing cost.

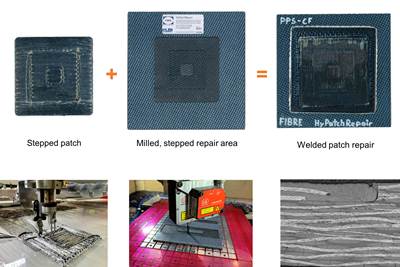

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Ginger Gardiner

Senior Technical Editor, CompositesWorld

Thermoplastic overmolded thermosets, 2-minute cycle, one cell

Adhesive-free, functionalized hybrid composites enabled by industry-first, integrated molding cell.

Read MoreComposite radar masts assembled for megayachts

Vabo Composites designs, builds and assembles 10m-tall composite radar masts, improving weight, stability and performance for modern megayachts.

Read MoreLeveraging composites for space tourism

Virgin Galactic’s WhiteKnightTwo will carry its SpaceShipTwo to launch position, then rocket passengers to suborbital space for a heavenly view of Earth.

Read MoreThermoplastic composites: Scenic view

First use of thermoplastic composite guide rails to replace aluminum brings many benefits to fixed-glass, roller-blind sunroof modules.

Read MoreThe International 14: High-tech but still accessible

Naval architect Paul Bieker and Henderson Boat Co. team take this venerable marine racing class to a more affordable performance/cost combination.

Read MoreInfused wing sheds light on aerocomposites future

In the Irkut MS-21 infused and co-cured wings, the aerocomposites industry gets a glimpse of how out-of-autoclave technologies might be applied to primary aircraft structures.

Read More

.jpg;maxWidth=300;quality=90)