As much as the aerocomposites industry says that it wants to get out of the autoclave and into fabrication technologies capable of faster throughput, the truth is that the autoclave is proving a difficult habit to break. It has to its credit decades of industry experience, mountains of applicable processing data to guide its reliable use, and plain old familiarity. And, quite simply, when it comes to the one job that matters more than all others when making composite primary structures — consolidating the laminates of very large composite structures to very low levels of void content — no other equipment or process does it better.

Proof of this is not difficult to find. Aerocomposites for the Boeing 787, the Airbus A350 XWB and the forthcoming Boeing 777X all feature major aerostructures fabricated with carbon fiber prepregs in massive autoclaves. But, with these three programs in early or full production, the aerocomposites industry is looking to the future, and one of the big questions is whether out-of-autoclave manufacturing processes have a role to play on next-generation aircraft programs. Can they do what the autoclave does (or do it well enough to meet spec) at a rate that will satisfy OEM desires to pick up the pace of production on future aircraft models?

Getting out of the autoclave means moving away from prepreg materials, which have been the mainstay of aerocomposites manufacturing for decades. The alternative to prepreg is to begin with a dry fiber form, which must be impregnated with resin, either via vacuum bag infusion or resin transfer molding (RTM), each of which has its own challenges. The two biggest challenges, particularly in relation to aerospace manufacture, are consistent fiber wet-out and porosity, the latter of which must be less than 2% to meet OEM strength and stiffness requirements. The thermoset-based, non-prepreg process most discussed as a viable option for getting out of the autoclave and meeting those challenges is vacuum-bag resin infusion.

Infusion is not new to composites fabrication in general, but has seen limited use in primary aerostructures, and almost no use in commercial aerostructures. There are, however, two major exceptions: The wings for the Bombardier CSeries single-aisle commercial aircraft feature dry fiber infused via a process Bombardier calls resin transfer injection, or resin transfer infusion, but the process does employ an autoclave. The second, however, is the carbon fiber composite wing structure for the single-aisle MS-21 passenger aircraft under development by Irkut Corp. (Moscow, Russia). The process also involves infusion, but is done entirely out-of-autoclave (OOA), which makes it truly unique in the aerocomposites industry. This aircraft is quietly proving to the aerocomposites industry the viability of large, infused, OOA primary structures for commercial aircraft. In short, the MS-21 is shaping up to be that first next-generation aircraft.

The specifications

The MS-21 (also sometimes referred to as MC-21) was designed and is being assembled by Russian OEM Irkut, but composite structures for the MS-21 are being fabricated by sister company AeroComposit (Moscow). Both companies are owned by United Aircraft Corp. (Moscow).

Two MS-21 test aircraft have been built to date. First flight was achieved in May 2017 and the plane is expected to enter the market in 2020. It features two Pratt & Whitney PW1000G or Aviadvigatel PD-14 turbofan engines and has a range of 6,000-6,400 km. The plane will be offered in two configurations, the MS-21-200 (132-165 passengers) and the MS-21-300 (163-211 passengers). There are 175 firm orders for the plane, almost exclusively from Russian carriers/leasers, including Aeroflot, Red Wings Airlines, UTair, Ilyushin Finance Co. and VEB Leasing.

In addition to the outer wings, the MS-21 also will feature infused carbon fiber composites in the wingbox. But autoclaved carbon fiber prepreg will form the wing trailing and leading edges, flaps, spoilers, ailerons, engine fan cases, and interior floor panels and floor beams. Glass fiber composites will be featured in the nose cone, cargo bay floor panels, the leading edge of the vertical tailplane and wing-to-body fairings. Aluminum and other metals will be used to fabricate the fuselage skin, stringers and frames, as well as all doors and wing slats.

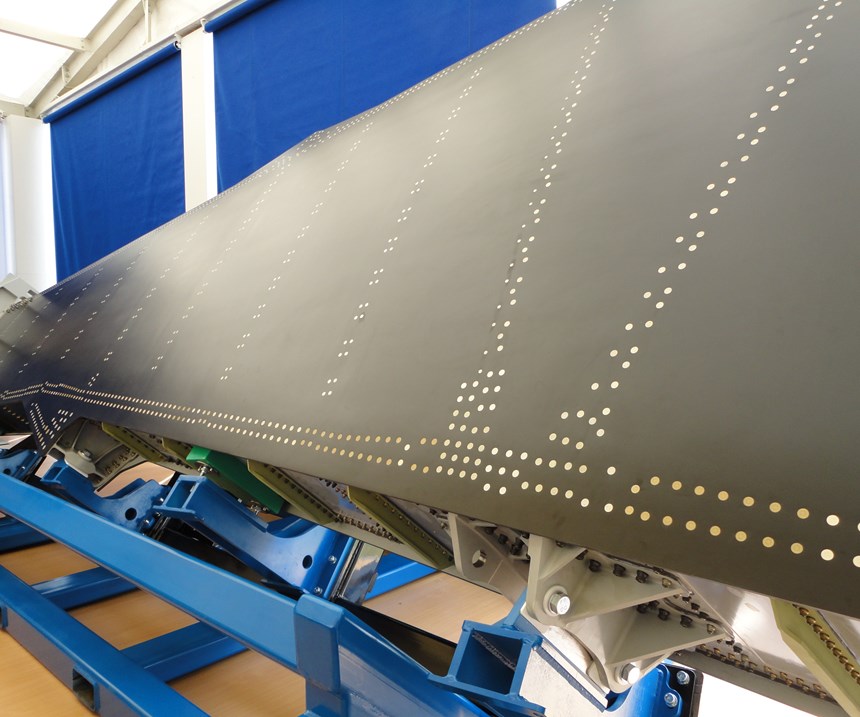

Placing, infusing dry fibers

The MS-21 outer wings feature a standard design that includes an upper wingskin, a lower wingskin, stringers on the inside of each skin, ribs running perpendicular to the stringers, and forward and rear spars. All parts are composite except for the ribs, and the skins and stringers are integrally molded and co-infused. Each outer wing is about 18m long and 3.5m wide at the root. The wingbox is manufactured separately and integrated with the MS-21 fuselage at Irkut’s final assembly line.

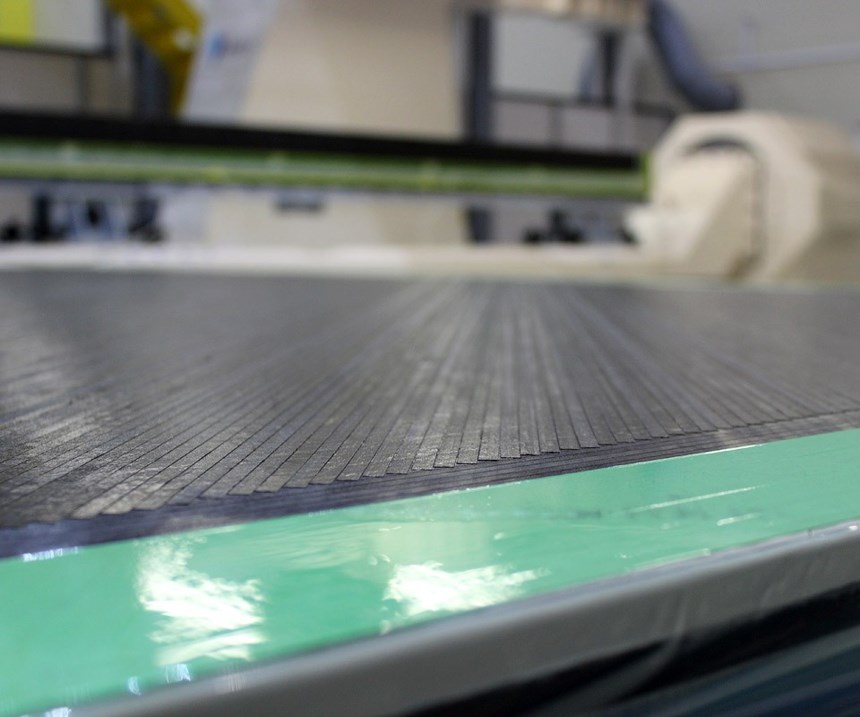

AeroComposit’s goal with the MS-21 wing and wingbox was not only to employ OOA infusion, but also to do so with as much automation as possible. Further, the company wanted, wherever possible, to co-infuse composite structures so as to minimize postmold assembly and mechanical fastening. Meeting this challenge would require the use of automated tape laying and fiber placement (ATL/AFP) systems to lay down dry fibers. That presented an additional challenge: Placement of prepregs, whether by hand or machine, offers the advantage of tack that helps stabilize the stackup and minimizes ply-to-ply slippage. Dry fibers, conversely, are inherently untacky and, therefore, must be modified if they are to be successfully used in automated placement.

Sam Hill, applications and research engineer, Solvay Composite Materials (Alpharetta, GA, US), who consulted with AeroComposit on materials and processes development for MS-21 wing fabrication, says Solvay was tasked with solving that problem and developing the wing’s infusion material system. Solvay’s PRISM TX 1100 is a slit tape comprising Teijin’s (Tokyo, Japan) IMS65 24K tow UD fiber and Solvay’s CYCOM 7720 binder, which, when heated, offers the tack needed to provide ply-to-ply friction. Further, topping each tape is a lightweight veil (proprietary Solvay technology) designed to provide weft stability, perme-ability for the infusion process itself and enhanced mechanical performance. For infusion, Solvay developed PRISM EP2400, a single-part 180°C-cure, toughened epoxy with a low-viscosity/temperature profile that enables injection at temperatures as low as at 70°C. The resin offers a wet Tg of 150°C and — designed expressly for use in fabricating primary aerostructures — it has an infusion open time of about 8-10 hours, says Hill.

How it’s done

AeroComposit operates two plants that fabricate composite parts and structures for the MS-21. The first, in Kazan, Russia, does the autoclave-based fabrication, such as ailerons, rudders, flaps, spoilers and air brakes, as well as the nose of the plane and the tailplanes. The other site is in Ulyanovsk, Russia, where the infusion work is done on the wings and wingbox in a 11,000m2 cleanroom.

Irkut’s decision to infuse the MS-21 wing and wingbox dates back to the plane’s launch in 2009. Irkut could have employed conventional prepreg/autoclave technology, but opted instead to leap-frog legacy materials and pursue first-of-its-kind infusion. It did not do so alone. AeroComposit had help not only from Solvay, but also, initially, from partners Diamond Aircraft (general aviation), aerocomposites manufacturer FACC (Ried Im Innkreis, Austria), automation specialist MTorres (Torres de Elorz, Spain) and infusion equipment specialist Stevik (Cergy, France).

AeroComposit did much of its own research and development to understand how use of infusion would affect wing design and manufacture. Anatoly Gaydansky, general director at AeroComposit, says trial and error was a consistent theme. “We encountered a lot of difficulties,” he said. “First of all, the uniform permeability of such a large-sized part as a wing panel was a challenge. We were confronted with the task to fully exclude the possibility of dry spots and potential cracking that may occur in the process of thermosetting.”

Maintaining tolerances for all manufacturing operations presented several difficulties, he says. These issues were partially addressed by adjusting and optimizing the manufacturing processes. In some cases, AeroComposit modified the infusion process, which in turn was followed by modifications in the tooling. The company also had to overcome springback when the part, after being freed from the tool, tended to change its geometry. “We were forced to introduce specialized devices and additional fixtures to improve the manufacturing accuracy at different stages,” Gaydansky says. “It is a huge package of manufacturing solutions. Sometimes, when these measures proved to be insufficient, we had to introduce changes into the wing design.”

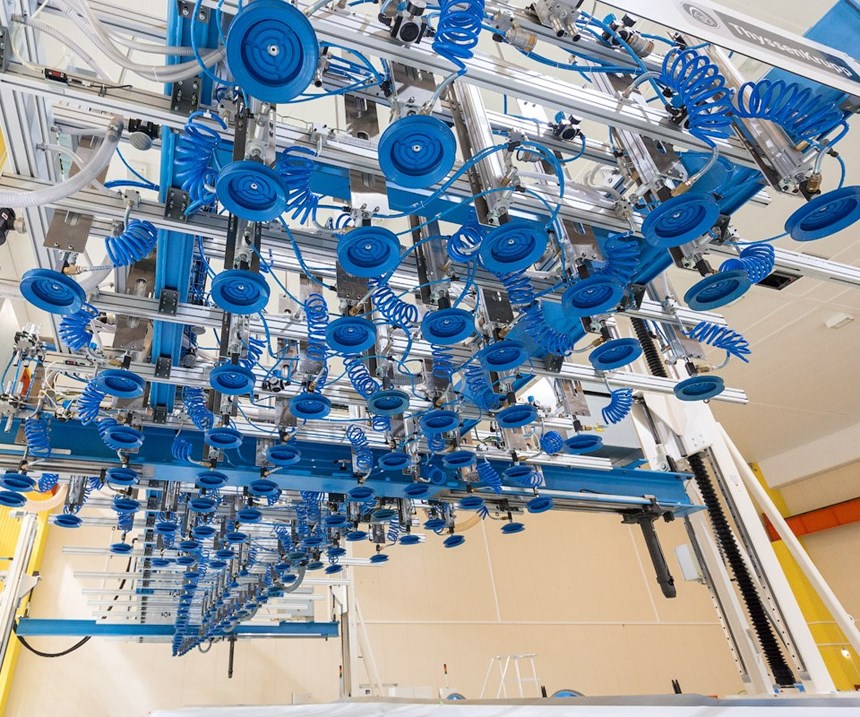

Arguably, the most complex structures AeroComposit fabricates are the co-infused wingskins and stringers. Dry fiber-placed separately, skins and stringers are then brought together for co-infusion. Wingskin layup is relatively straightforward and involves automated fiber placement (AFP) of the 0.25-inch Solvay PRISM TX 1100 dry fibers on an Invar tool, performed with a Coriolis Composites (Queven, France) AFP system using a KUKA Robotics 6-axis robot (Steps 1 & 2).

Meanwhile, says Gaydansky, the stringers are also laid up via AFP as flat preforms, about 100 mm wide and in varying lengths, using the same PRISM TX 1100 material. Each flat preform is then hot-formed to create an L-shaped preform. “After that, the two L-shaped halves of a stringer are connected together, resulting in a T-shaped stringer,” says Gaydansky. “Further on, using special equipment supplied to us by Dutch-Shape [Borne, The Netherlands], the part is cut to specified geometry and installed on the wing panel.” Each stringer is supported on the skin by Invar tooling, which clamps together to maintain the desired T shape (Step 3).

Gaydansky says AeroComposit uses vacuum bag infusion: “The technology developed by our company involves the installation of two membranes,” he notes. “Besides, we are practicing our own patented scheme of vacuum bagging. One might as well say that we have created still another version of infusion technology, specially adapted for building large-size primary structural elements.”

“After the stringers set is installed on the wingskin preform, it is wrapped in a number of auxiliary materials,” Gaydansky says. “For bagging, we apply vacuum membranes, breathing and draining materials. Tubes are installed for resin supply and for vacuum level control. Finally, all is covered up with a vacuum-bag film which is secured and sealed along the perimeter of the preform, after which vacuum is applied.” Infusion, he says, is done at 100°C, followed by cure at 180°C. AeroComposit uses a standard curing oven, supplied by a European manufacturer, that measures 6 by 22m. The entire infusion and cure process takes just less than 24 hours, followed by trimming, routing, drilling and cutting via a CNC machine (Step 4) provided by MTorres. Finished wingskins are nondestructively inspected (Step 5).

Meanwhile, in parallel, AeroComposit fabricates the C-shaped forward and rear spars. These also are made with the PRISM TX 1100 material, laid up on a male mandrel, using an MTorres AFP system (Step 6). Infusion of the spars typically takes 12 hours, using the same cure profile as the skins/stringers. The thickness of the spars ranges from 6-14 mm, and they benefit, says Solvay’s Hill, from the steerability and low bulk of the material.

“The microstructure of TX 1100 provides the ability for the tape to bond to the adjacent layer,” he says. “In addition, the tape is able to manipulate without changing the form. As you steer the tape, you can recognize the limits of how much you can steer the tape by how much it starts to develop defects.” This capability is important because, conventionally, composite spars are fabricated in sections, which are subsequently bonded or fastened together. This is necessary to accommodate direction and angle changes designed into the forward and rear sections of the wing. The steerability and low bulk of TX 1100, says Hill, allows AeroComposit to change directions and fabricate each MS-21 spar as one structure.

Nondestructive testing (NDT) is performed with one of two systems (Step 7). The first is an ultrasonic system supplied by Tecnatom (San Sebastian de Los Reyes, Spain). It applies phased arrays via a 7-axis robot, using converters that were specially designed and manufactured for the AeroComposit-Ulyanovsk facility. The Tecnatom system is equipped with an automatic head changer to minimize touch labor. The second NDT system is a mobile Omniscan machine produced by Olympus (Waltham, MA, US). This water-based system uses C-scans and reportedly can scan at high speed to check quality and integrity.

Upper and lower wingskin/stringer structures and front and rear spars, when cured, are then joined with the metallic ribs. “This is performed in a customized, automated assembly jig procured from MTorres,” says Gaydansky. “This is high-precision assembly equipment that allows us to position and fix large-size panels to the pre-assembled structural frame, composed of spars and ribs. Here, mechanical fasteners are used for attachment. Fixation of wing panels to the structural frame is implemented with titanium fasteners.”

One of the biggest uncertainties facing the use of OOA infusion to fabricate large primary composite aerostructures revolves around questions of porosity. As is well known, the aerospace industry expects less than 2% porosity in its composite structures, which is typically easily achieved with autoclave cure. Can infusion, limited as it is by atmospheric pressure, meet that porosity threshold? Gaydansky says the infusion process developed by AeroComposit typically provides less than 1% porosity.

Going forward

AeroComposit has completed prototype manufacturing and is in early stages of production of the MS-21 wings. Gaydansky says, “We have already accomplished the manufacturing of 10 shipsets of the outer wing. The full manufacturing cycle of composite parts, starting from the layup of the preforms and until they are delivered for assembly, takes, as of now, approximately two months.”

As serial production ramps up, he says, the composite part cycle will take about one month. The assembly process, at the moment, requires four months; in serial production, it will be less than three months. Thus, the total time to build a wing, in production, is expected to be about four months. Gaydansky says the infused outer wings have completed static testing, which “demonstrated that the strength characteristics of the composite wing are not lower than the design values.” Fatigue testing will be done later in 2018.

As an early adopter, AeroComposit, and by extension, Irkut, have done a significant amount of the troubleshooting required to apply new materials and processes to aircraft manufacturing, and they clearly have developed a viable system for wing and wingbox fabrication. The remaining challenge appears to be one of rate. How might the aerocomposites industry apply AeroComposit’s lessons to other aircraft? Frank Nickisch, director of strategic projects, composite materials aerospace at Solvay, believes that just having applied infusion successfully is a major milestone. However, he contends, “The big challenge is cost and rate at the end of the day. I think a few things will need to come together to make infusion a winning solution: Mechanical performance, design integration, automation of manufacturing process. This will need to be really efficient. We need to get labor out to be really cost-competitive.”

Related Content

PRF Composite Materials introduces RP570 FR eXpress cure prepreg system

Ultra-fast, fire-retardant formulation targets snap cure press molding of structural components.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreBusch expands autoclave solutions

Busch announces its ability to address all autoclave, oven and associated composites manufacturing requirements following the acquisition of Vacuum Furnace Engineering.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)