Airtech launches recycled-grade Dahltram T-100GF resin

Thermoplastic polymer resin was designed to tackle distinctive industry challenges of large-scale 3D printing while also assisting with sustainability initiatives.

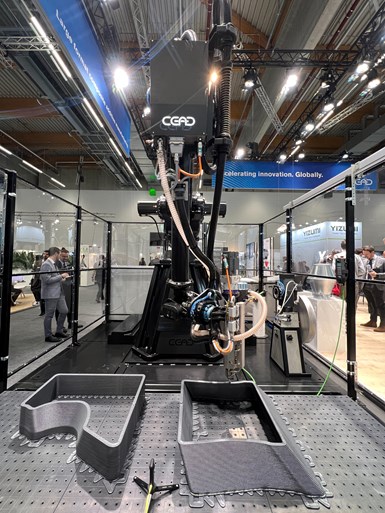

Live printing using the Dahltram T-100GF resin. Photo Credit: Airtech Advanced Materials Group

Dahltram T-100GF resin is Airtech Advanced Materials Group’s (Huntington Beach, Calif., U.S.) first recycled-grade thermoplastic polymer resin for pellet-fed, large-scale 3D printing. Developed with precision, the material was designed to tackle distinctive challenges of large-scale 3D printing while contributing to sustainability initiatives in the industry.

Dahltram T-100GF combines the power of recycled grade co-polyester resin with the strength of fiberglass reinforcement, resulting in a sustainable material that is suitable across diverse applications, including rapid prototyping, low-temperature molding, trimming tools, architectural structures, casting patterns and more. Airtech says it remains commited to expanding its product line with solutions that drive sustainability and contribute to a greener future through the use of large-scale additive manufacturing (AM) technologies.

Other benefits of Dahltram T-100GF resin beyond sustainability include the resin’s strength and durability. The inclusion of fiberglass reinforcement improves the material’s strength, promoting good durability and reliability across a spectrum of applications. The resin is also highly versatile, catering to a range of applications from rapid prototyping to architectural structures, offering an adaptable solution for manufacturers across various industries.

Dahltram T-100GF also provides an economically attractive alternative to traditional materials while still delivering performance. Airtech says this makes the resin an option for businesses aiming to streamline their production processes without compromising quality.

Related Content

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.