Airtech resins approved for use on Thermwood 3D printers

Airtech has partnered with Thermwood Corp. to ensure its Dahltram resins meet and exceed the requirements for 3D printing on Thermwood’s LSAM platform.

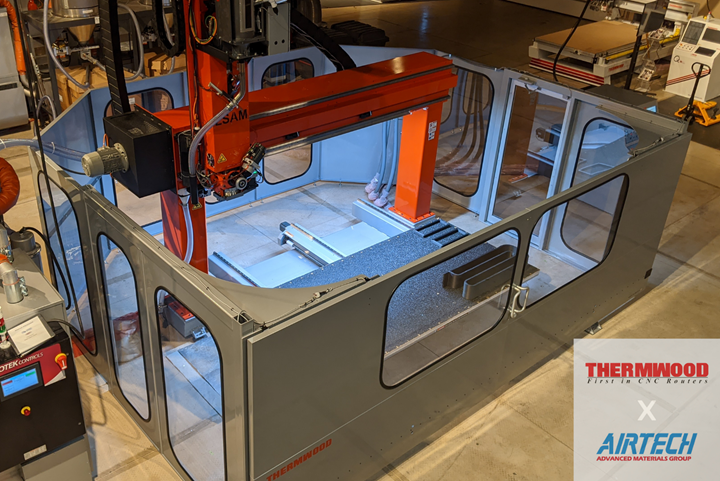

Airtech Advanced Materials Group (Huntington Beach, Calif., U.S.) has expanded its portfolio with a line of resins for additive manufacturing. Airtech partnered with Thermwood Corp. (Dale, Ind., U.S.) — a manufacturer of industrial, large-scale 3D printers and five-axis routers — to ensure Airtech’s Dahltram resins meet and exceed the requirements for 3D printing on Thermwood’s LSAM platform.

Thermwood says its LSAM technology delivers high-performance tooling, masters, patterns, molds and fixtures at high throughput to near net shape, with precision and vacuum integrity. Airtech plans to actively maintain its collaboration with Thermwood in the development of new materials and expanded functionality.

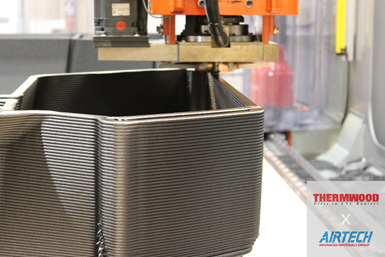

Airtech’s Dahltram resins are used for large scale printing on Thermwood’s LSAM platforms. According to Airtech, the Dahltram resins are well suited for composites fabrication, as well as metal fabrication and direct to part applications. Airtech says they are suitable for multiple print platforms, providing production flexibility with end-use material validation. Airtech has reportedly completed more than 300 autoclave cycles to date.

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

.jpg;maxWidth=300;quality=90)