Arris Composites wins BIG Innovation Award for advances in manufacturing

Company awarded for Additive Molding technology, enabling the future of manufacturing across multiple industries.

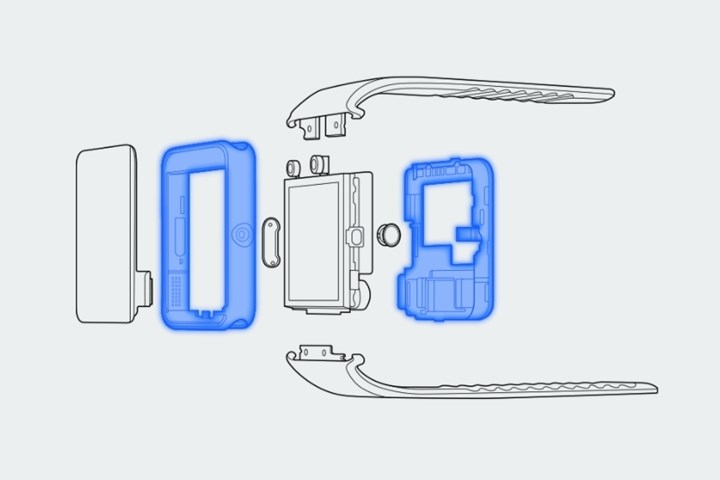

Arris Composites’ smart watch. Photo Credit: Arris Composites

Arris Composites (Berkeley, Calif., U.S.) developer of Additive Molding technology for the production of high-performance composites in mass-market products, announced on Jan. 12 that it has won the BIG Innovation Award.

Presented by the Business Intelligence Group, the annual BIG Innovation Award recognizes organizations, products and people that are bringing new ideas to life in innovative ways. Arris was selected for its innovative approach to manufacturing. The company’s flagship technology, Additive Molding, is a high-speed manufacturing process that allows for the precise alignment of continuous carbon fibers and embedding of electronic components and multifunctional materials into a single topologically optimized part or component. Arris says the result is a cost-effective method for manufacturing lighter, stronger, faster and more intelligent products at scale (Arris Composites also recently had an in-depth discussion about its Additive Molding process with CW).

“More than ever, the global society relies on innovation to help progress humanity and make our lives more productive, healthy and comfortable,” says Maria Jimenez, COO of the Business Intelligence Group. “We are thrilled to be honoring Arris as they are one of the organizations leading this charge and helping humanity progress.”

“At Arris, we’re on a mission to reinvent manufacturing and deliver the products of the future,” adds Ethan Escowitz, CEO of Arris. “We’ve successfully demonstrated how our technology can transform products in terms of design, weight, performance and sustainability. We’re honored to receive the Big Innovation award and be recognized for our contributions to the future of manufacturing.”

Arris’ Big Innovation award is the latest recognition for the emerging company. Most recently, Arris’ Additive Molding Carbon Fiber Truss won the Red Dot: Design Concept 2020 award, the largest professional design concept competition in the world. The company has also recently teamed up with Skydio to revolutionize drone design and manufacturing, and has received investment from Robert Bosch Venture Capital to bring advanced composites to new sectors.

Related Content

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Filament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.