Arkema aids in construction of 45-foot fishing boat using Elium

Inshore vessel is the largest yet to incorporate the recyclable thermoplastic resin, promotes future sustainability in boat manufacturing.

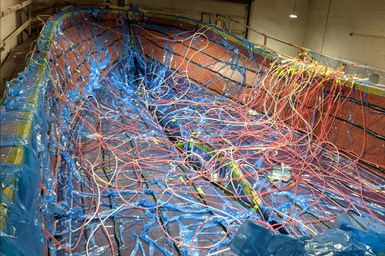

Arkema (King of Prussia, Pa., U.S.) and CCNB-INNOV (New Brusnwick, Canada), a college that supports applied research activities and encourages innovation, in partnership with boatbuilder DJ Marine (Pointe-Sapin, New Brunswick), have recently completed a 45-foot inshore fishing boat constructed entirely with Elium thermoplastic resin. The fiberglass vessel is said to be the first of its kind — the largest boat yet produced using this recyclable resin — and paves the way for further sustainability in boating manufacturing.

“Elium resin is our solution for a sustainable future for boat manufacturing,” Nicolas Valloir, business manager for Elium resins at Arkema, shares. “We are proud of this achievement and are excited to see the next generation of boats embrace this recyclable material for their construction. It is special that Arkema is helping to make that a reality.”

The boat was manufactured via conventional infusion. Arkema notes that it was very conscious about not having any vacuum leak to perform a state-of-the-art infusion. One of the key challenges the company faced was injecting high amount of Elium for the first time.

For related content, also read “Fully recyclable composite mold incorporates Arkema Elium resin.”

Related Content

-

The AAMMC Tech Hub: Ramping U.S. production of large thermoplastic composite aerostructures

CW talks with Syensqo, Spirit AeroSystems and other consortia members about current funding, specification of the next world’s largest press, organizational structure and projects to support U.S. companies in the race to deliver >40,000 sustainable and efficient aircraft over the next 20 years.

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

-

Composites end markets: Sports and recreation (2025)

The use of composite materials in high-performance sporting goods continues to grow, with new advancements including thermoplastic and sustainability-focused materials and automated processes.