Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

(Top left, clockwise)Orange City, Iowa, facility and QForge automated thermoplastic composites facility, interiors production in Renton and aircraft duct assembly shop in Sumner. Source: Sekisui Aerospace

Sekisui Aerospace (Renton, Wash., U.S.) is a Tier supplier of high-volume, complex composite parts and assemblies to Boeing, Spirit AeroSystems, Collins Aerospace, GE Aerospace and others. In addition to supplying 10,000 parts/year for aeroengines and 150,000 parts/year for commercial aircraft ducting and interiors, it also manufactures 100,000 carbon fiber-reinforced thermoplastic composite brackets per year in its fully automated QForge line. The company’s diverse mix of products includes primary structure splice straps to join composite fuselage sections, medical imaging and surgical tables, as well as wings, fuselages and flight control structures for military and commercial unmanned aerial vehicles (UAV).

Its process capabilities are also wide-ranging, including complex prepreg layup with autoclave and out-of-autoclave (OOA) cure, but also extensive work in high-temperature materials such as bismaleimide (BMI) and compression molding for serial production as well as quick prototyping of high-precision aeroengine blades, thrust reverser cascades and electric motor components. Sekisui Aerospace has also extended its thermoplastic composites capabilities with a continuous compression molding (CCM) line and automated stamping cell.

In addition, it has invested in Industry 4.0, implementing RFID tracking on material kits, molds and parts in progress. Tags are read by antennas integrated with software to visualize not only where parts are but where they should be with a green or red status for each production area. This system has improved efficiency and reduced scrap and nonconforming parts in Sumner. At Orange City, tag/barcode data is fed into the site’s supervisory control and data acquisition (SCADA) system enabling smart presses that load process recipes per part, monitor all process data, notify operators of potential issues and log the data into each part’s digital thread.

Sekisui Aerospace’s vision to be the supplier of choice for composite parts is also focused on people. CW’s tour of all three sites revealed a noticeably diverse workforce, including many women and people of color in managing roles. The company’s focus on kaizen (“change for better”) recognizes its workers’ expertise, solicits suggestions and tracks management’s response and implementation. CEO Daniele Cagnatel has drawn fire for challenging the industry’s low wages. “Forget about $18 or $20 an hour,” he says in a February 2023 Seattle Times article. “Why can’t we pay $30 an hour?” His vision is to use more automated and digitized workflows to provide highly paid careers for a smaller number of skilled workers with fewer managers. “I want to hire workers who will operate automated cells and inspect the parts produced,” he tells CW. “So, now they’re managing digital systems and should be paid more but they’re also more efficient and thinking how the cells can be improved and what we can do next. Then we start to give people a career, not just a job.”

This transformation started in 2017, he says, when he left GKN Aerostructures North America as CEO to join AIM Aerospace (Renton, Wash. U.S.) which had just acquired Quatro Composites (Orange City, Iowa, U.S.). AIM was then acquired by Sekisui Chemical (Tokyo, Japan) in 2019. “We have already come a long way,” says Cagnatel, “but over the next 5 years, we will turn this company into a very different type of business.”

Orange City, Iowa

CW’s tour of this 9,300-square-meter facility is led by the site’s general manager, Luke Livingston, and engineering manager, Andy Stoebner. They point out the site’s Special Award trophy from the 2023 Global Kaizen Competition. “We won for all of Sekisui North America [nine companies, 24 sites], demonstrating scrap reduction and process improvement in complex prepreg beavertail parts for Collins Aerospace nacelles,” says Livingston. “Kaizen achieves improvement by taking apart a problem or process, analyzing it and then putting it back together in a better way. Sekisui Chemical has participated in this global competition for 50 years and Sekisui North America for 25 years.”

We enter the production floor in the shipping area, where we see a large variety of parts. A crate to the left holds multiple carbon fiber-reinforced polymer (CFRP) medical imaging tables as well as splice straps for the Boeing 787 composite fuselage. These mate the tail cone to the fuselage and are made in four pieces that are joined into hoops with bolts via CFRP splice plates.

In the adjoining cleanroom, four Zünd (Altstätten Switzerland) automated ply cutters have dynamic nesting capability. “We can nest hundreds of plies for multiple parts for different customers on the same prepreg material roll, which significantly improves our efficiency,” says Stoebner. The beavertails, for example, have 60 plies. On the right side of the room are the cutting tables and one of six large vacuum forming tables throughout the plant for heated debulk of layups. On the left are layup stations using laser projectors, most having twin projectors mounted on posts.

Compression molding expertise. Sekisui Aerospace won the 2023 Global Kaizen Competition Special Award for its scrap reduction on a compression molded CFRP prepreg part (top). This expertise extends into molding compounds and prototypes such as this high-precision cascade for an aeroengine thrust reverser (bottom).

Compression molding expertise. Sekisui Aerospace won the 2023 Global Kaizen Competition Special Award for its scrap reduction on a compression molded CFRP prepreg part (top). This expertise extends into molding compounds and prototypes such as this high-precision cascade for an aeroengine thrust reverser (bottom).“Half of our layup stations are for parts that will be compression molded, like these beavertails,” says Stoebner. “The other half are layups that will be autoclave cured and are mostly for Boeing.” As we walk past the beavertail layup station, a technician lays plies on a rectangular mandrel-like tool. “These are all CFRP plus some SurfaceMaster [Solvay, Alpharetta, Ga., U.S.] plies,” he adds, “and will be made using our proprietary pressclave process.” Past this is an area filled with 5-6 stations where BMI prepreg is laid up for GE Aerospace engines used in Boeing aircraft. We exit the cleanroom into an area with four autoclaves from ASC Process Systems (Valencia, Calif., U.S.). In front of the largest is a set of interior and structural parts for Gulfstream Aerospace, vacuum bagged and on top of carts, ready to be cured.

Compression molding, pressclave, 4.0 cell

We turn left and head into a production area that is mostly used for compression molding of prepreg parts. There are several large presses — 0.8 × 2 meters, 1.3 × 1.3 meters and 0.5 × 2.4 meters — and 13 smaller presses, a mix of Accudyne Engineering and Equipment Co. (Bell Gardens, Calif., U.S.), Wabash MPI (Wabash, Ind., U.S.) and machines built in-house. Compression molding is split into four types by the tooling used: latex rubber bladders, matched metal dies/molds, silicone intensifiers and the pressclave process.

The pressclave imitates the autoclave but uses less energy and offers quicker cycle times, explains Stoebner. “We can produce multiple nacelle panels per shift where it would take at least 6-8 hours to cure in an autoclave. However, we can stack many parts in a single autoclave run. So, there is a sweet spot for value in the autoclave’s ability to run many parts versus the quick turn of press molding.”

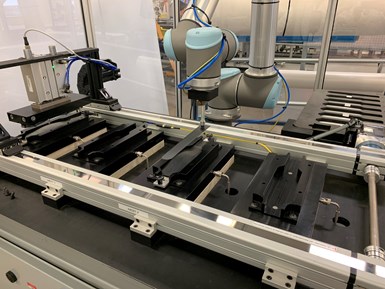

Industry 4.0 cell for aeroengine part. A cobot picks prepreg plies from a shadow board (right rear), removes backing paper and places them into tools (front left) where a camera checks accuracy and a compaction unit slides over, using a roller to apply pressure.

We move to an enclosed cell using a cobot (Universal Robots, Odense, Denmark). “We’re trying to implement more Industry 4.0 and automation throughout our processes,” says Livingston. “This cell performs layup, compaction, press molding, post-cure and machining within a 6 × 6-meter area.” It was built in-house and is used to produce a family of spacers for two models of GE aeroengines. The robot grabs a ply of precut prepreg from numbered, shaped holes in a shadow board tray. It then removes the backing paper and places the ply. A camera checks that the paper is removed and the placement is correct, and then a roller compacts the ply. This is repeated for each ply until the layup is complete and is transferred to the press.

In the rear of the cell, parts are fed directly from the press to several Haas (Oxnard, Calif., U.S.) machining cells. An operator transfers the parts from the press into the machining cells. “Our next iteration will automate this step,” says Livingston.

He notes this cell is also the result of a kaizen project to improve flow and efficiency. “It cuts down on material handling and the operator having to move so much,” he says. “Sekisui Chemical has been a wonderful parent company to invest in us, especially during COVID-19, to increase our technical capabilities and production capacity so we’d be ready when the aerospace market returned.”

Tooling and product development

The next area houses a 1.2 × 1.2 × 3.7-meter five-axis machining cell from CMS North America (Caledonia, Mich., U.S.) and two 1.8 × 2.4 × 4.3-meter Zimmerman (Neuhausen, Germany) cells. “We also have multiple three-axis machining cells, a table router and a five-axis waterjet cutter,” says Stoebner. “So, we can machine our own molds and fixtures. We have a blue light scanner to ensure tolerances, and this allows us to be a one-stop shop, with the ability to design and produce our own production tools and help our customers do this as well. We also build our own CFRP tools.”

Next, we walk into the new product introduction area, where work is being completed for a major manufacturer of electric vertical takeoff and landing (eVTOL) aircraft that is pursuing certification. “We’re working with them [the customer] on design for manufacturing and tooling design for multiple parts of their aircraft including wing ribs, stabilizers and ruddervators and also on testing,” explains Stoebner. “We’re working to industrialize the layup process,” he adds, pointing to two medium-sized metal tools with CFRP prepreg layups. He then turns to a partially filled floor-to-ceiling rack. “This is specifically for that customer and the 300+ layup mandrels and machining fixtures that will be required for us to meet their needs.”

On a table at the front of this area are several compression molded parts that look like large watch gears. “We are working with motor manufacturers to replace metal with CFRP in eVTOL and automotive electric vehicles,” says Stoebner. “We have trialed a variety of approaches including hybrids of unidirectional materials and chopped fiber as well as compression molding compounds.”

Industry 4.0 smart presses

We walk across the aisle to rows of Accudyne Engineering and Wabash presses. “We’ve put our own HMI and controls on these machines so we can monitor and collect the process data,” says Stoebner. “The operator will scan the barcode on their badge, on the tool being used and on the part layup. All this feeds into our SCADA system, which will then pull up the correct recipe for that part. The operator loads the tool and closes the press. During cure, we will collect all process data — e.g., temperature on the tool, pressure in the press and inside the bladder tools — for full traceability on each part. We know who loaded the part and when, plus the full run data versus the recipe. Instead of using human eyes for checking, we use automation. If the system analysis shows the process data aligns, then the screen signals green. If there is any issue, the screen signals red. For example, if the cure calls for a ramp of 2 degrees/minute for 40 minutes, but the machine was off, then we go look at that to determine if the variation is enough to call the part quality into question. This is building in a cure check like you have in standard autoclave software, but it’s all dialed to the specifications per each customer and part.”

Testing and NDI

Next, we pass an area where parts are being load tested. “Medical components such as surgical tables for hip replacement surgery are 100% tested, including for torsion and displacement,” says Stoebner. “We do similar tests for UAV parts. We record test data and camera footage of the tests and log all of this for statistical process control. Parts rarely fail during testing, but if one does, we can trace root cause very quickly.”

We then pass through a set of doors into a room for dimensional control testing and nondestructive inspection (NDI). On the left are two bridge CMM (Hexagon Manufacturing Intelligence, North Kingstown, R.I., U.S.) and on the right is a Creaform (Levis, Canada) blue light 3D scanning system which collects 1.8 million data points/second compared to the lab’s Faro arm at 10-15 data points/minute. The Creaform is used for building heat maps of parts, annual tool inspections and in development, for example, to help customers reverse engineer parts without CAD files.

In the back, a flash thermography booth developed by NASA sits to the right. Thermography uses light or heat to excite a part’s surface and records the temperature conduction to confirm features and identify defects. The thermography booth has been here for 6-7 years and is currently used for inspecting bonds on UAV parts. Previously, this was done using handheld A-scan ultrasound testing (UT) and required 32 hours for just one bond area. Now, all the bond areas are scanned in 4 hours. On the left is a C-scan UT unit with dual squirter/test heads in a frame that holds samples horizontally with one head above and one below. A new 1.5 × 1.5 × 3.7-meter C-scan system from Tecscan (St-Bruno-de-Montarville, Canada) is also being installed.

Paint, finishing, assembly

We exit the NDI room into the paint and finishing area which includes two paint booths, one paint mixing booth and one paint oven. To the right is an enclosed room with six downdraft tables for sanding and other pre- and post-finishing operations. Back to the left, there are numerous stations for edge sealing and a variety of finishing processes.

Next, we pass two rooms for assembly operations, such as the integration of molded parts for UAV fuselages including bonded clips for fuel lines and other attachments. “As part of our kaizen philosophy, we keep improving this process,” says Stoebner. “For example, we use an overhead camera to check the component positions and help us analyze our operations. We bring in people from other disciplines in the company to help us look for further improvements in quality and efficiency.” Outside of this room are stacked a variety of compression molded parts for defense applications.

QForge automated TPC

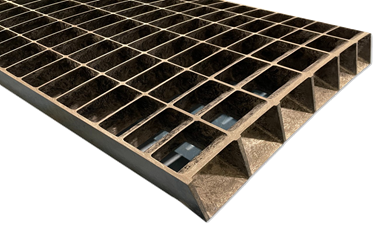

The tour moves across the street to the QForge building which is 100% thermoplastic composites (TPC) via a fully automatic production line developed in-house. “It was started in 2012 as a manual line, moving tools from preheating ovens to presses,” explains Livingston. “We then added an overhead rail system and automation. This line currently produces 8,000 parts/month, including 30 different part numbers for engine brackets and interior stowbin brackets for the Boeing 787. Before COVID-19, we were ramping to meet Boeing’s rate of 14 aircraft/month. The line is currently set up for small parts, less than 0.5 × 0.5 meter. But we are already preparing for an expansion to handle larger parts.”

The QForge tour starts in the material prep room where CF/PEEK UD prepreg tape is chopped into two different sizes and stored in plastic bins. “This is an extremely automated process,” notes Livingston, “with one machine that converts the raw material to what we load into the tools on the line.” We exit into the production area where a row of 10 ovens (Wisconsin Oven Corp., East Troy, Wis., U.S.) sit opposite a row of five automated presses with a Fanuc robot on a rail in between.

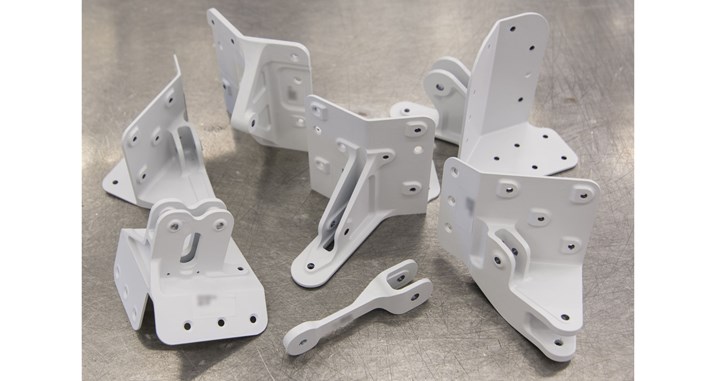

QForge 99.9% first part yield. The QForge automated line produces 30 part numbers of thermoplastic composite (TPC) brackets for engine and interior stowbins at a rate of 8,000/month.

At the end is a tool storage area with a conveyor line encircling it, loaded with matched metal tools. The operator and digital control system sit between us and the conveyor. “The system sees the Boeing part number and quantity from our SCADA system,” explains Stoebner. “It loads the tools into the conveyor and shows the operator the weight and type of material to load. Thermocouples in the tool measure the temperature, and when it reaches what is required in the spec, the system moves it to the press. The part number, tool number, material type and weight and all process data are logged.”

After the system completes molding and machining, an operator loads parts onto the overhead rail that transports them through “boxes” for grit blast, primer application, ambient solvent flash, topcoat application and paint oven. The rail then transports the tools into an adjoining area for quality inspection. Here also, any required components such as helicoils will be installed. When asked if this production line could handle the expected advanced air mobility (AAM) part volumes, Livingston notes plans to extend this building and install another line. “We are poised for growth.”

Renton, Washington

CW’s tour guides for this 11,600-square-meter facility are Brian Baker, director of operations and Darek Downing, director of thermoplastics operations. The tour begins in the site’s open production area, which is filled with production stations mainly for Boeing interior parts. A large stockroom to the left is being transitioned to use RFID tags, which will also be used on parts, tracking their location as well as state of progress, adds Baker.

“This location has a lot of older processes, such as crushed honeycomb core for interior panels,” says Baker. “Most of what we do in this area uses glass fiber prepreg and roughly 20% is Kevlar.” We turn right into the production area and walk toward the ovens. On our left are shaped access doors and panels for 777 and 787 aircraft. “These require nine processes,” says Baker, “including hand layup of prepreg, vacuum bag and oven cure, quality inspection and then water test to make sure the panels provide a barrier without any leaks.” The panels then have different sections of core drilled out, rivets are installed, areas receive filling and fairing, panel edges are sealed with potting compound and any secondary trim pieces are installed, followed by a decorative exterior surface film.

Toward the back of this area is a large oven. A vacuum bagged layup sits in front, ready for cure, which is 4-5 hours for most parts. To the right of the oven is a demolding station. After this, parts will be placed on vacuum fixtures for drilling holes and sanded to smooth any sharp edges and corners, followed by the paint station and then final quality assurance (QA) inspection. “Boeing picks up these finished panels every day and puts them straight onto their aircraft [10 minutes away] with no further checks,” says Baker. “This requires >99% yield from us.”

Ergonomic layup

We exit the main production room and enter a cleanroom on our left. Two automated cutters — one from Zünd and one from Gerber (Tolland, Conn., U.S.) perform all of the prepreg kit cutting. In the middle of the room, several part layup production lines comprise carts on rails. “But we’re changing this, based on our operators’ suggestions, to tables that can be raised or lowered as needed to meet the worker’s height for improved ergonomics,” says Baker. A Lazy Susan on top enables the part to spin around for applying the plies more easily.

In the back section of this cleanroom is an area where 10-12 different part numbers for shaped service panel covers are being laid up. To the right is a large oven where interior parts are cured. There are also several molds that look like vacuum tables but are actually OOA tools with a reusable silicone vacuum bag attached to a frame for the top mold and used for Boeing parts.

Cure, machining, finishing

The adjacent cure room features a 1,000-ton press by Williams White & Co. (Moiline, Ill., U.S.) and two smaller presses from Accudyne Engineering, one steam and one oil, for curing flat panels. With metal separators in between, up to seven parts can be cycled through a 5-hour cure. There are also four presses for curing cargo liners, which are also stacked and cured in multipart sets.

We pass into an area where parts are manually trimmed but this will soon be transitioned to automated CNC mills, says Baker. Adjacent bays house five-axis CMS Ares and DMS (Colorado Springs, Colo., U.S.) CNC centers plus four smaller trim cells.

In the fill and fair room, workers at six stations apply filling compound and sand interior parts smooth as needed. Shaped seat backs using overexpanded Nomex honeycomb core wait to be finished. Nearby is a large paint room where primer, topcoat and finish coat are applied in separate bays and cured in two paint ovens. After the paint room is a touch-up room where decorative films are applied and a light table for quality inspection. We walk back through the hallway to the main production area, where a large board tracks progress on kaizen initiatives. “These were suggested by our workers, and we meet each week to review and make sure we’re implementing them in a timely manner,” says Baker.

CCM, APC and thermoplastic parts

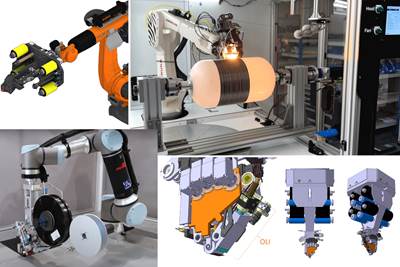

CCM and APC for automated TPC production. Sekisui Aerospace has installed a continuous compression molding (CCM) line (top) in its Renton main production hall to produce tailored thermoplastic composite (TPC) blanks which are then stamp formed in its automated press cell (APC) comprising two banks of ovens, an Accudyne Engineering press and KUKA robot (bottom).

At the entrance to the main production area is the CCM cell supplied by Teubert (Blumberg, Germany). “We’re in the process of qualifying this process with Boeing,” explains Downing, who spent 10 years developing CCM and other processes at ATC Manufacturing (Post Falls, Idaho, U.S.). The cell comprises a creel with up to 21 rolls that feeds different angled tapes (e.g., 0°, 90°, ±45°) into the heated platen press for consolidating into flat tailored blanks. The press has three heating zones, two cooling zones and can apply up to 180 tons of pressure. “We can make 100-meter-long sheets of 610-millimeter-wide blanks,” says Downing, “for example, comprising 59 plies of Teijin CF/PPS tape with 40% resin content. We’ve made panels with up to 80 plies for R&D programs, but typically use 48 plies for production parts.”

We proceed through a door to the automated press cell (APC) where CCM blanks are first trimmed to shape on an OMAX (Kent, Wash., U.S.) waterjet cutter and then stamped into parts. It looks very similar to the stamping cell at Victrex Composites Solutions, with four preheat ovens and a robot in the middle. Parts are shuttled between two banks of two ovens each and one Accudyne Engineering press by two KUKA (Augsburg, Germany) robots.

“We have four ovens to keep up with the short press cycle,” notes Downing. “We could make millions of parts/year in this cell. We have two loading bays bringing a part back to the operator every minute.” These will be trimmed next door in two Haas CNC cells and then be inspected in a robotic NDT cell by Genesis (no longer in business) which performs ultrasonic C-scans on parts in an immersion tank.” Demonstrator parts on view include omega/hat stiffeners and a deep, three-sided U-beam part.

Innovation Lab

At the front/east side of the production hall, a full testing lab performs mechanical, fire and qualification testing. Adjacent to this is the Innovation Lab, which was relocated from Poway, near San Diego, after Sekisui bought AIM Aerospace, says Baker. “This lab supports not only R&D for continuous improvement of our parts and processes, but also develops a wide variety of new parts. We can go from concept to parts very quickly, building our own prototype or low-rate tooling. For example, we went from design to three shipsets of parts in 3 weeks for a UAV customer.”

The lab includes a Stratasys (Eden Prairie, Minn., U.S.) Fortus 400 3D printer for plastics (not composites), Haas CNC mill, small Accudyne Engineering vertical press, larger Wabash flat platen press and two smaller presses for first concept panels. Parts seen here include a curved rib beam made from Orange City’s Q-forge material and an aeroengine thrust reverser cascade made with compression molding compound. “This is a really difficult part because not only is it curved to conform to the nacelle, but each fin in the cascade is at a different tilt angle,” says Downing. Baker adds that this lab has prototyped parts for automotive and military applications, as well as for newer mobility and UAV companies. “We’re looking at New Space as well. Our goal is to significantly diversify into new and non-aerospace applications within the next 5 years.”

Sumner, Washington

CW’s tour guide for this 9,300-square-meter facility is Ed Cranford, director of operations, who spent 20 years at Boeing before coming here. We enter the cleanroom, featuring one Zünd and one Gerber automated cutter. “We’ve increased the automation and optimization of our kits, cutting plies closer to net shape instead of larger pieces which were hand trimmed,” he says. “We’ve now eliminated 90% of hand trimming. We have two people per shift, responsible for 200-250 kits/day.”

“We make only duct parts and assemblies here,” he continues. “Most of it uses Kevlar prepreg for HVAC systems in Boeing aircraft including the 737, 787, 767 tankers, 777 and the P-8 military version of the 737. We also make the packboard storage boxes for the escape slides for Airbus and some parts for military aircraft heat exchanger systems. We make more than 3,000 different part numbers that vary a lot — some use two plies, some as many as 30 plies, one may be a high-volume single part at 38/month while others are lower rate but with more parts per shipset.”

In the back half of this room are stationary lines for parts that use 15-30 plies, where each technician performs all the layup steps, from beginning to end. In the center of the room are parts on carts that move down rails where each technician does only one layup step — e.g., initial plies, precut honeycomb core, final plies and then bleeder, breather and vacuum bag film, followed by a station where the layup is sealed with tape and vacuum ports are installed.

The layups are applied onto plaster mandrels, most used only once, says Cranford, due to the complex part shapes. “It’s too hard to get the plaster out of the part, so it is broken up. These plaster layup mandrels [LM] are made in a dedicated facility that’s five blocks away. We then treat them with Frekote mold release [Henkel, Düsseldorf, Germany].” There are a few reusable LM for very simple parts on the left side of the room. They have no spud projections, says Cranford, and thus, are easier to remove. For parts that do have spuds, the vacuum bagging on completed layups is complex. “We use heat guns to soften the prepreg in order to push it into corners to avoid bridging.” Cycle times for layup range from 26 minutes for the lowest ply, simplest parts to 900 minutes for parts with 30+ plies and more complex shapes.

Autoclave area, preheat room

We exit the cleanroom into the left of two main traffic aisles that run from the front/north of the building to the back. Looking down this aisleway, to the left is an autoclave/oven cure area followed by the shipping /receiving bay and then the breakout/demolding area where plaster LM are removed. To the right is an island of offices for engineering and production support. Behind those offices at the rear of the building is the assembly area and final QA inspection stations.

A sea of blue plaster layup mandrels just outside cleanroom being processed for ramp-up in Boeing 787 production.

We walk through the cure area with three ASC autoclaves and eight ovens on the left, plus two more ovens on the right. Oven cures take 5-10 hours while autoclave cures can require 6-20 hours. “We are in the process of installing a fourth autoclave from ASC which is 3 times larger than our current largest, in preparation for growth beyond ducts,” notes Cranford. Also to our left is the heat room, where certain LM are preheated before layup to facilitate prepreg draping for very complex shapes. Beyond the ovens on the right is a sea of blue plaster LM being processed for Boeing’s ramp-up in 787 production. “There are 400 plasters in the building right now getting prepped,” says Cranford.

RFID tracking, visual factory

Ducting layup, assembly, digitization. Sumner facility layup room, assembly of ducts with multiple spud projections, and bonded details and digital dashboard showing production status.

Ducting layup, assembly, digitization. Sumner facility layup room, assembly of ducts with multiple spud projections, and bonded details and digital dashboard showing production status.

Cranford explains the site’s RFID system. “Every plaster LM gets an RFID tag and so does every prepreg kit which becomes a part in progress. The top sheet in the work order traveler shows multiple codes for materials, LM/tool and cure details. One tag references all codes in the work order. As the traveler moves through the facility, it gets read by antennas. Software generates a map showing where every traveler is in the facility.”

We turn right off the west corridor and cross the building to face a widescreen computer monitor on the wall in the east corridor. “This dashboard is part of a system that we’ve developed with the software company, Xemelgo [Bellevue, Wash., U.S.],” explains Cranford. “It shows the plant floorplan, blocked out by color to indicate our production status and will track every step up to shipping parts out.”

“We have thousands of parts,” he continues, “so it was easy to lose one and also to lose tools. But now, we’ve reduced our expediters that track the parts from 15 to three. Now, we use them for other tasks, including how to make the RFID system work even better. Our goal is to continue to decrease scrap and advance the visual factory. Our production control personnel have now become our manufacturing experts and work with our customers to develop automated reports to give the timely data and updates requested. We’re also starting to tag even our trim tools and large LM tools for inventory control and to streamline and optimize the maintenance these require.”

LM breakout, parts finishing, QA

Here, technicians remove the nonreusable plaster LMs from inside cured parts. They first cut off the bagging material and then vibrate out the plaster. Parts are then matched with the appropriate trim tool and sent to the trim room. Broken out plaster is sent to a recycling company.

The first section of the trim room is an area where additional laminate “beads” for attaching ducts together are added, after which the parts are oven cured. The rest of the shop is filled with ventilated cells where various trim operations are carried out. “We’ve built shadow boards for each cell, so operators have the right tools for their job,” notes Cranford.

We exit the trim shop to the north and into a large area dedicated to assembly. “Every part that is trimmed comes through these doors and is checked by an RFID reader,” says Cranford. “The inspector here is our gatekeeper and performs the first QA inspection before assembly. We build all the details that are used to construct these higher level assemblies. Assembly jigs are used to locate the duct with spuds in the right layout to add the details. For some parts, we also add high-temperature insulation and a final high-temperature film cover. Every duct then goes through a pressure test at the rear of the assembly shop. We fill the part with pressurized air to make sure there are no leaks.”

In the back left corner of the assembly area is the paint shop which comprises pre-paint prep areas, paint booths to apply primer, static conditioner and then topcoat, plus a paint cure oven. Back out into assembly shop and toward the rear are two stations for final QA inspection. The digital system scans the RFID tag and loads the part information. If the part passes inspection, the operator enters that data and the system marks it as complete and then automatically prints the material lot number, part number and process data onto the part. “Every part we ship has to have this marking,” says Cranford.

Streamlining, vertical storage units, growth

“When I came here, this plant was AIM Aerospace,” notes Cranford. “First thing, I removed 50% of the workstations to reduce clutter. We still made the same number of parts, but started to improve our yield, which was only 40%. We then started to look at the linear flow of work in each area and reorganized to reduce operators running back and forth. The team was great and wanted to find ways to do things better. And when Sekisui Chemical came in, I was so impressed with the company culture and management’s vision for all three plants.”

We walk back toward the front of the building and see a large machine that Cranford explains is an automated vertical storage unit. “We have two of these, one to store the details we use to complete duct assemblies and then one on the other side for storing assembly jigs,” says Cranford. “This is because we make different parts at different times depending on the program and rate.” Again, the goal is to reduce clutter and enable fast location when details and tools are needed.

“Next, we’ll do this with our trim jigs and reduce the footprint of those racks by 50%,” says Cranford. “This will make space for us to add new operations. Last year, we cleared 30-35% of the storage space on the other side, enough to install the new autoclave.” Before he ordered the equipment, he asked the cure department how they wanted the area to be configured and improved. “They said they wanted one central workstation to monitor all the ovens and autoclaves. So, that’s our next step. We also need to reduce our impact on the environment. The plaster shop already recycles and has its own kaizen team and we’re starting to look at other initiatives. It’s all about growth, not just in your production, but in your vision for what could be.”

Sekisui Aerospace tomorrow

Sekisui Aerospace has already started to diversify away from commercial aerospace which Cagntael sees as locked-in legacy systems and materials. Investments made during COVID-19 have indeed helped win new business so that 30% of revenue is now nonaerospace. “And we will increase that to 70%,” he says, “which provides us more freedom to use materials like thermoplastics, which can be made in minutes, not hours, and with processes that require less energy.”

He notes the company’s digitization will also increase, which opens even more possibilities. “When we started tagging parts at Sumner, the idea was to better locate parts for efficiency. But then the digital team asked, ‘why don’t we let the system tell us where the parts should be?’ That has resulted in a new level of ownership — scrap went down to <2% and there are hardly any nonconforming parts for review. That technology increased empowerment and improved the overall factory just by switching how we used it. The key is not to just automate what we do but to find new ways to do things. These materials, processes and digital tools are meaningless if we don’t use them to enable new ways of doing business and helping our customers. So, we are becoming more and more an innovative composite solutions company.”

Related Content

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

Read MoreRead Next

Creating a culture of excellence in aerocomposites

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read More

.jpg;maxWidth=300;quality=90)