AMULET project funds 24 projects in composites, CMCs, metals

Trans-European project finalists for first open call identify material and process innovations in building, aerospace and aeronautics, energy and automotive sectors.

Share

AMULET — Advanced Materials and Manufacturing Technologies United for LightwEighT — is a cross-regional project that seeks to make a significant contribution to reducing CO2 emissions in the European Union (EU) by strengthening innovative, lightweight construction in SMEs. Its focus on light metal alloys, ceramic matrix composites (CMC), polymer-based composites and their implementation in automotive, aerospace, energy and construction industries has been realized through the winners of its first open call, which took place July-December 2022.

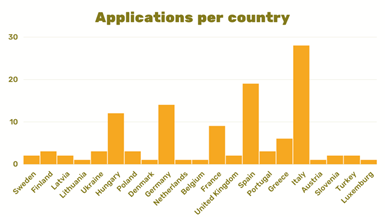

The AMULET consortium received 59 applications and will fund 24. Those 24 projects comprise SMEs from the building (6 applications; 10.7%), aerospace and aeronautics (31 applications; 55.4%), energy (7 applications; 12.5%) and automotive (12 applications; 21.4%) sectors across 119 entities 21 European countries. Among materials selected, polymer-based composite materials constituted the largest percentage (71.8% applications), following CMC (20.5%) and light metal alloys (7.7%).

The following are finalists for each category:

Aerospace and aeronautics

Polymer-based composites

- Ultralight landing gear for UL helicopters by composite process innovation — Coordinated by EAST-4D Carbon Technology GmbH (Germany), partnered with Carbon Design Sp. z o. o. (Poland)

- Quality UD Tape Control — Coordinated by Canonical Robots S.L. (Spain), partnered with Nanosens İleri Teknolojiler Enerji Makine Proje Ta (Turkey)

- Innovative and Safe Multi Aircraft Light Landing Gear — Coordinated by CES Works (France), partnered with ProdVirtus Lda. (Portugal)

- ULR High-Energy Absorption Composites Landing Gear — Coordinated by Composites ATE S.L (Spain), partnered with Texfire Textils Tecnics S.L. (Spain)

- Sustainable Composite Landing Gear — Coordinated by Fuko srl (Italy), partnered with Turtle Srl (Italy)

- Computer-Aided Development and Make of Composite UL Helicopter Landing Skid — Coordinated by eCon Engineering Mernoki,

Szolgaltato Korlatolt Felelossegu Tarsasag (Hungary), partnered with Hungaro-Copter KFT and Orca Aerospace Kft. (Hungary) - Innovative Lightweight Helicopter Landing Gear for a Greener and Cleaner Aviation — Coordinated by Advanced materials testing and consulting SL (Spain), partnered with Compoxi SL (Spain)

-

Smart Impact A&A_PBC_CompoGEA — Coordinated by SpacEngineer Lda. Portugal (Portugal), partnered with ST Composites (France)

CMC

- Lightweight CMC High-Temperature Fan for Aerospace Applications — coordinated by Walter E.C. Pritzkow Spezialkerami (Germany), partnered with Nablawave SRL (Italy)

Light metal alloys

- Wet Layup/Vacuum Bag Process Optimization for Lightweight Aircraft Structures — Coordinated by Rescoll (France), partnered with Titania ensayos y proyectos industriales S.L. (Spain).

-

3D Preform-Reinforced Ceramic Composite Material — Coordinated by Fureho AB (Sweden), partnered with ECM Engineered Ceramic Materials GmbH (Germany)

Automotive

Polymer-based composites

- Front End Module Becomes Sustainable by Flax — Coordinated by B PREG Kompozit ve Tekstil Müh. Dan. San. Tic. A.Ș (Turkey), partnered with W8SVR GmbH (Germany)

- Child Seat Headrest Made From Recycled Thermoplastic Straps — Coordinated by Silbaerg (Germany), partnered with Ł.Karwala Spółka Komandytowa (Poland) and thermoPre GmbH (Germany)

- Fire-Proof Thermoplastic Composites for EV Batteries — Coordinated by Plasticos Industriales Bocanegra (Spain), partnered with Avanzare (Spain)

- Fire-Resistant Additives for Continuous Fiber Thermosets (Epoxy-Glass) — Coordinated by PolymerOn Kft. (Hungary), partnered with QDevelopment Kft. (Hungary)

- Composite PP Front End Module — Coordinated by Iltar-Italbox industrie riunite SpA (Italy), partnered with Tecnostamp Srl (Italy)

- Eco-Housing for E-Mobility — Coordinated by Lavoisier Composites (France), partnered with Vibratec SA (France)

-

Graphene-Coated Glass Fibers for Fire-Resistant Composites for Battery Housing of EVs — Coordinated by Grafren AB (Sweden), partnered with Sixonia Tech GmbH (Germany)

Building

CMC

- 3D Printing Materials Based on Magnesium Oxide Binder — Coordinated by Georg Breitenberger individual company (Austria), partnered with TEC Eurolab srl (Italy)

- Lightweight Autohealing Mortar for External Thermal Insulation Building Systems — Coordinated by Tesela, Materiales, Innovación y Patrimonio S.L. (Spain), partnered with Chemical Building Project S.L. (Spain) and Gatim S.R.L (Italy)

Energy

Polymer-based composites

- PVTEG Generation — Coordinated by Coesa Srl (Italy), partnered with R2M (Spain)

- Modular Fiber-Reinforced Battery — Coordinated by Liber SRL (Italy), partnered with Baruffi Engineering S.r.l (Italy)

- TEG-Comp (TheroElectrically Enabled Composites) — Coordinated by Velidakis Emmanouil “Get 3D” (Greece), partnered with Vogiaridis Panagiotis (Greece)

- Prepreg Carbon Composite Solution Using Immersion Cooling for Lightweight and High-Performance Pack — Coordinated by Canoe (France), partnered with E-Mersiv (France)

For more in-depth information about each finalist project and its goals, please visit this link. A second call will eventually be organized.

Related Content

New CMC turbine vanes successfully tested in wind tunnel

SiC/SiC ceramic matrix composite (CMC) inlet guide vanes for a high-pressure turbine are aimed for a geared turbofan and show promise for more efficient aeroengines with less weight and need for cooling.

Read MoreThe future of quartz and oxide fibers at Saint-Gobain Advanced Ceramic Composites

New business builds on 100-year legacy in quartz, prepares for growth, while starting production of oxide fibers to meet increased demand for CMC by aerospace and industrial sectors.

Read MoreConverting carbon fiber for UHTCMC to 3500°C

Advanced Ceramic Fibers LLC demonstrates ultra-high temperature ceramic matrix composites using SiC and other metallic carbides for applications in aerospace, defense, energy and more.

Read MoreA different Ox-Ox prepreg for faster, more affordable CMC options

Isovolta has developed silica fiber/alumina CERAPREG to enable ceramic matrix composite parts with long-duration service at 900°C and handling similar to epoxy prepreg, dielectric performance similar to quartz.

Read MoreRead Next

National Composites Centre participates in Horizon Europe GREEN-LOOP project

Research-intensive 17-partner innovation project will develop new sustainable and circular strategies with novel bio-based products using rubber, bioplastics and wood composites.

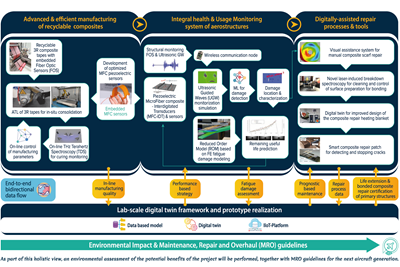

Read MoreEU-funded GENEX project to develop digital twin framework for aircraft lifecycle tracking

Novel digital framework to enable holistic and comprehensive data capture through the entire aircraft lifecycle, supporting composite component/structure manufacture optimization and maintenance.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More