What CW's analytics have to say about 2021 composites trends

A look back on the most-read CW stories in 2021 tells us much about what to expect in 2022.

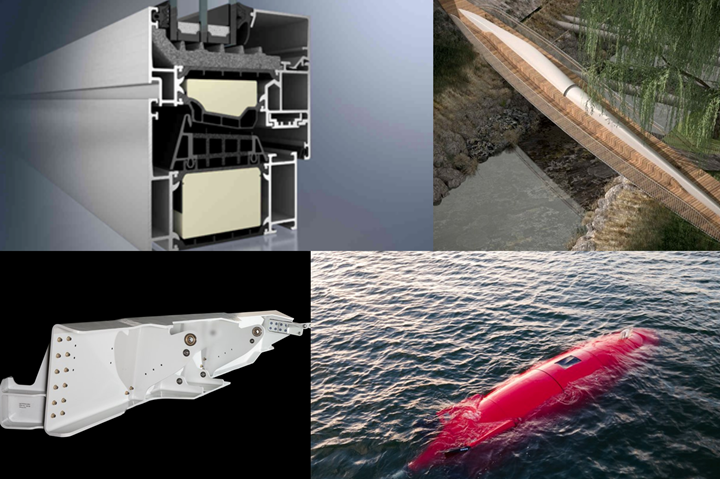

Photo Credit: (Top left) Schüco, (top right) Anmet, (bottom left) Daher, (bottom right) Dive Technologies

Happy New Year! (I am reticent to use exclamation points, so I hope you appreciate the gravity of the one I just used.) It’s mid-December as I write this and around this time each year the CompositesWorld team conducts a little inventory-taking of the year that was — particularly regarding our editorial performance.

Part of this effort includes publishing our annual list of top 10 articles and top 10 news stories of the year. Frankly, it’s hard to beat CW’s website analytics as a raw measure of the topics, applications and ideas that resonate with you, our audience. And looking more closely at the content that performed well last year tells us much — not just about what interests you, but also about where the composites industry is headed.

So, let’s take a closer look at CW’s best-performing stories in 2021 and see what we can learn. First, here’s the list of top 20 articles, with the broader topic and/or end market for each noted.

- Why aren’t composites synonymous with infrastructure? (infrastructure)

- Contactless measuring of temperature and pressure inside composites (process)

- Large-format 3D printing enables toolless, rapid production for AUVs (3D printing, marine)

- Novel dry tape for liquid molded composites (material, aerospace)

- Out-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow (material, process, aerospace)

- Wing of Tomorrow ribs: One-shot, thermoplastic, OOA consolidation (material, process, aerospace)

- Braided carbon fiber and resin transfer molding for complex composites (material, process)

- Recycling end-of-life composite parts: New methods, markets (wind energy)

- Advancing the OOA infused wing box (material, process, aerospace)

- Reprocessable, repairable and recyclable epoxy resins for composites (material)

- Porosity, voids and bridging in prepreg autoclave and vacuum bag-only laminates (process)

- Composites as auto body reinforcements (material, automotive)

- Challenges of laser-assisted tape winding of thermoplastic composites (material, process)

- Designing a versatile multi-material EV battery enclosure (material, automotive)

- Hydrogen is poised to fuel composites growth, Part 1 (hydrogen storage/pressure vessels)

- Composite thermal breaks boost window insulation value (material, construction)

- Stelia Aerospace Composites advanced hydrogen storage (hydrogen storage/pressure vessels)

- Composites testing challenges, Part 1: Introduction to mechanical testing of composites (testing)

- Manufacturing the upper half of the Multifunctional Fuselage Demonstrator (material, process, aerospace)

- Assessing a composites supply chain in flux (supply chain)

What did I notice? What surprised me most about this list was #1. This was an editorial I wrote for the June 2021 issue when President Biden’s Infrastructure Bill was still wending its way (slowly) through Congress. I am not sure what I wrote was particularly novel or noteworthy, but it clearly tapped a nerve regarding the lack of, and potential for, composites use in infrastructure applications.

You will also notice several stories (#4, #5, #6, #9, #19) are focused on aerospace, with a clear trend toward out-of-autoclave materials and process combinations that will, almost certainly, drive composites fabrication for next-generation aircraft programs. It’s also worth noting that each of these stories involves companies/organizations — Daher, GKN Aerospace, MTorres, Airbus, Clean Sky 2 — that are based in Europe. Indeed, Europe is driving much publicly funded R&D aimed at progressing commercial aerospace materials and processes.

I was pleasantly surprised to see CW’s newest column, called The Troubleshooter, make the list, checking in at #11 and #13. We launched The Troubleshooter in 2021 to help our audience address common composites manufacturing challenges. The column’s popularity with readers sends a clear signal for its continuation in 2022.

Hydrogen, not surprisingly, appears twice on this list, at #15 and #17. The value of carbon fiber-overwrapped pressure vessels for hydrogen storage is turning into a massive market opportunity for the composites industry — one that is simultaneously exciting and daunting. We will continue to watch this space closely in 2022.

The automotive end market is represented in #12 and #14, the latter of which is a report we did on a multi-material battery enclosure for electric vehicle (EV) applications. Enclosures, like hydrogen pressure vessels, are turning into an application that stands to benefit greatly from the benefits composites convey. And with EV on the rise, demand for composite enclosures promises to skyrocket.

Finally, this list ends as it began, with another editorial I wrote. My May 2021 column, #20, was about the challenges posed by composites industry supply chain disruptions. It turns out I was too optimistic in that column, suggesting we’d see supply chain problems ironed out by the end of the year. Nevertheless, this month’s Composites Index report and a new year offer some hope for a change for the better.

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreSinonus launches energy-storing carbon fiber

Swedish deep-tech startup Sinonus is launching an energy-storing composite material to produce efficient structural batteries, IoT devices, drones, computers, larger vehicles and airplanes.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreBraided thermoplastic composite H2 tanks with co-consolidated molded boss areas to fit EV battery space

BRYSON project demonstrates possible designs, automated manufacturing and low permeability concepts, including EVOH liner and novel PPA matrix.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More