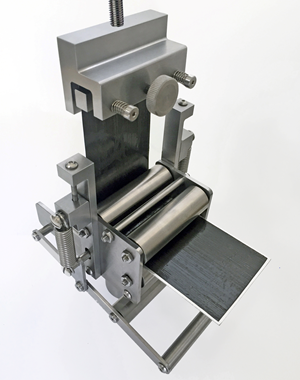

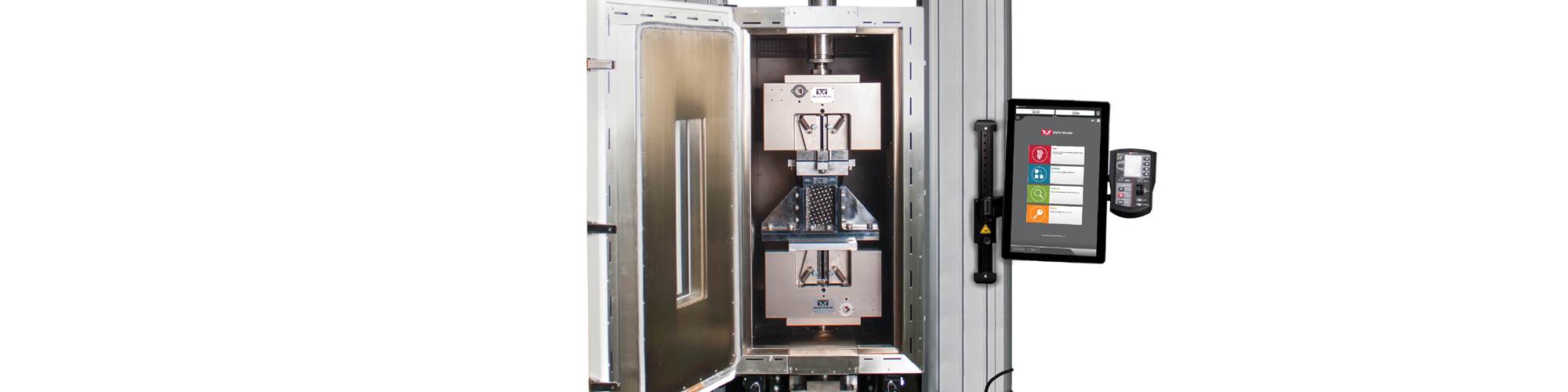

Figure 1. Composites testing system configured for compression after impact (CAI) testing at temperature. Photo Credit: Instron

Compared to traditional structural materials, polymer matrix composites (PMC) offer greatly enhanced performance and flexibility. However, these benefits come at the cost of increased material complexity, and it is easy to overlook the challenges of producing high-quality test data to support the needs of materials development, design and quality control.

Basic characterization of material properties requires a range of tests to be performed under different loading conditions — tension, compression, shear and flexure. Many composite materials are anisotropic (meaning the mechanical properties depend on direction) and inhomogeneous (meaning the material composition is not uniform; for example, a matrix with embedded fibers). For critical composite applications, additional, more complex tests are often needed to determine the material’s durability under service conditions and in representative environments. For example, it is important to evaluate damage tolerance with compression after impact (CAI) testing for composites in the aerospace industry, fatigue loading in the wind energy sector and high-rate tension testing for automotive crash protection.

There are a wide range of international and national test standards (ASTM, EN, ISO, JIS) developed to test composite materials, along with several historic standards that are still in use, such as those published by SACMA (Suppliers of Advanced Composite Materials Association) and CRAG (Composites Research Advisory Group). In addition, auditing bodies such as Nadcap further define equipment performance criteria such as specimen alignment. A few of the more common mechanical tests for composites are discussed below.

Test types

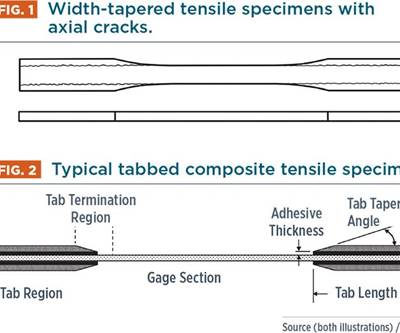

Tensile testing. In-plane tensile testing of composite laminates is the most common test performed on composite materials. Tensile tests are also performed on resin-impregnated bundles (tows) of fibers to determine fiber properties and through-thickness specimens (cut from thick sections of laminates) to determine through-thickness properties.

Examples of standards for the in-plane tensile testing of laminates are ASTM D3039, EN 2561 and ISO 527-4/5. Specimens are generally parallel sided with bonded tabs to prevent the grip jaws from damaging the material and causing premature failures. Reducing the width of the gauge section is not recommended due to the likelihood of premature shear failures; however, some small and gradual reductions in the width of composite specimens, along with the use of flat grip jaws with high-friction coatings, can eliminate the need for tabs.

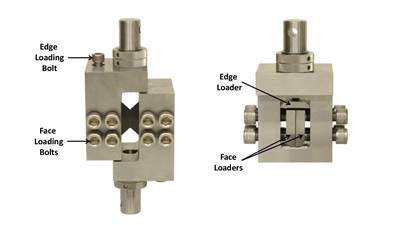

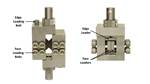

Compression testing. Composite laminate compression specimens are either parallel sided with a short, unsupported gauge length to prevent buckling, or have a longer gauge length with lateral supports to control buckling. Test forces may be introduced by either shear loading, end-loading, or a combination of shear and end-loading (combined loading). A variety of compression test standards and fixtures are in common use, like ASTM D695, ASTM D3410, ASTM D6641 and ISO 14126. It is also possible to perform compression testing between hydraulic grips, provided they are well aligned and have high lateral stiffness.

Shear testing. The interlaminar shear strength test (ILSS), or short beam shear (SBS), is a simple test performed using a small specimen loaded in a three-point bend configuration. The ratio of the specimen thickness to the support span generates a shear failure along the centerline of the specimen. ILSS standards in common use include ASTM D2344, EN 2563 and ISO 14130. The ILSS test provides an apparent strength value rather than a true material property; nevertheless, it is an effective and widely used comparative QC test.

In-plane shear properties can be measured by performing a tensile test on a specimen with a ±45-degree fiber orientation. Shear strain is determined from axial and transverse strain measurements. As in the ILSS test, this test does not provide a true value for the shear properties because the stress in the specimen is a combination of shear and axial stress. Common standards for this test include ASTM D3518 and ISO 14129.

Determination of shear properties for design is usually determined using V-notched specimens, which can produce a pure shear state in the region of the notch (e.g., ASTM D7078 and ASTM D5379).

Compression after impact (CAI) testing. Damage tolerance is a major concern with composite laminates as invisible, internal delamination can lead to a significant reduction in strength. CAI testing provides a measure of damage tolerance. The CAI test is usually conducted on a rectangular laminate panel and consists of two parts. In the first part, the panel is subjected to a controlled impact using a drop tower. The panel is then supported in a jig and subjected to an edgewise compressive load until it fails. The failure load gives an indication of the residual strength of the panel after the impact damage. CAI standards include ASTM D7136, ASTM D7137 and ISO 18352.

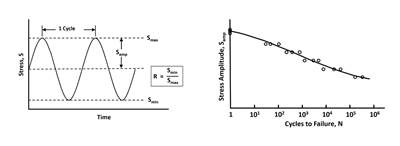

Fatigue testing. Compared to the large number of well-defined “static” tests on composite materials, the situation regarding fatigue testing of laminates is more open. Accurate alignment and correct gripping to avoid failures near the grip jaws are important, as is high lateral stiffness to prevent buckling in tests which include compressive loading. It should be noted that some of the anti-buckling guides used in “static” compression testing can be problematic if used in cyclic testing due to friction effects. When conducting fatigue tests on polymer composites, the maximum test frequency is usually limited by the need to limit the temperature rise in the test piece. For example, the maximum temperature rise recommended by the ISO 13003 fatigue standard is 10°C.

High-rate testing. The various test types described in this article are conducted at slow strain rates as dictated by the various standards. In some instances, such as when obtaining materials data for modeling crash behavior, tests need to be conducted at higher strain rates. Typically, the aim is to produce stress-strain plots for a material over a range of strain rates. High-rate tension or compression testing can be performed using either a drop tower with a high-speed force sensor or with a high-rate, servo-hydraulic testing machine. In performing this type of work, the servo-hydraulic testing machine provides a more flexible platform, can test over a wider range of speeds and can maintain a constant strain rate during the test.

Other mechanical tests. A variety of other standardized mechanical tests for composite materials are available. These include flexure testing, tension and compression tests on specimens with open and closed holes, bearing strength tests and inter-laminar fracture toughness tests.

Next month, part two of this three-part series will discuss the various options for measuring strain when testing composites.

About the Author

Ian McEnteggart

Ian has a physics degree from Birmingham University and has worked for Instron (Norwood, Mass., U.S.) for 41 years, currently serving as the composites market manager. In the field of composites, he is active in the development of international standards for materials testing and is chair of the BSI PRI/42 Composites Standards Committee.

Related Content

Composite prepreg tack testing

A recently standardized prepreg tack test method has been developed for use in material selection, quality control and adjusting cure process parameters for automated layup processes.

Read MoreMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreProtecting EV motors more efficiently

Motors for electric vehicles are expected to benefit from Trelleborg’s thermoplastic composite rotor sleeve design, which advances materials and processes to produce a lightweight, energy-efficient component.

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read MoreRead Next

Fatigue testing of composites

Fatigue testing may be performed at multiple points during the design of a composite structure. A focus on small-specimen level fatigue test methods, however, suggests a need for more testing method standardization.

Read MoreShear testing of high-shear strength composite laminates

CW columnist Dan Adams compares three V-notched shear test configurations used to measure the shear stiffness and shear strength of composite materials.

Read MoreTensile testing composites: Simple concept, difficult in practice

Dr. Daniel O. Adams, professor of mechanical engineering and director of the Composite Mechanics Laboratory at the University of Utah, and the vice president of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US), takes over for his father, Dr. Donald F. Adams, as the anchor writer in CompositesWorld magazine's revamped CW Design and Testing column. First subject? The challenges of tensile testing unidirectional composites.

Read More

.jpg;maxWidth=300;quality=90)