Layup molds, vacuum fixtures address aerospace tooling trends

CAMX 2025: Technical Tooling is integrating advanced materials, digital process compatibilities and automation into its low-CTE Ravin layup molds and Vacu-Grip fixture offerings to meet evolving needs.

Share

Technical Tooling (Tacoma, Wash., U.S.), showcasing Ravin layup molds and Vacu-Grip vacuum fixtures, demonstrates its alignment with leading trends in advanced aerospace tooling, such as out-of-autoclave (OOA) processing, automation and the integration of additive manufacturing.

Ravin layup molds, developed with advanced granular material and hybrid epoxy systems, deliver the low coefficient of thermal expansion (CTE), high dimensional stability and surface precision features vital for next-generation aerospace structures. Engineered to match the CTE of carbon fiber, Ravin is reported to offer Invar-level accuracy at a fraction of the cost and is suitable for both autoclave (capable up to 350°F, potentially higher for specific applications) and OOA processing.

Manufactured to near-net shape, these molds reduce lead times and waste while supporting rapid prototyping and scalable production. They achieve tolerances of 0.003" or better and surface finishes of RMS 32 or better. Their robust construction enables repeatable, high-precision layups for critical components like lip skins, panels and control surfaces — areas where lightweighting and tight tolerances are essential for performance.

Vacu-Grip fixtures use advanced vacuum technology to securely hold composite parts during layup, trimming and assembly, minimizing manual intervention and mechanical clamping. Shear holding force is typically more than two times that of v-groove fixtures, providing optimal part stability throughout processing. This not only increases throughput and precision but also supports the trend toward automation and digital integration in aerospace manufacturing. The fixtures’ adaptability for large format and complex geometries aligns with the aerospace sector’s demand for rapid, high-quality production of increasingly intricate composite structures.

According to Technical Tooling, both composite innovations are engineered to meet the aerospace industry’s evolving needs for sustainability, efficiency and high-rate production.

Related Content

-

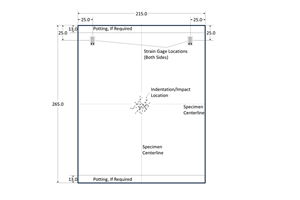

Testing to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

ASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Related Content

Testing to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MoreDamage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More