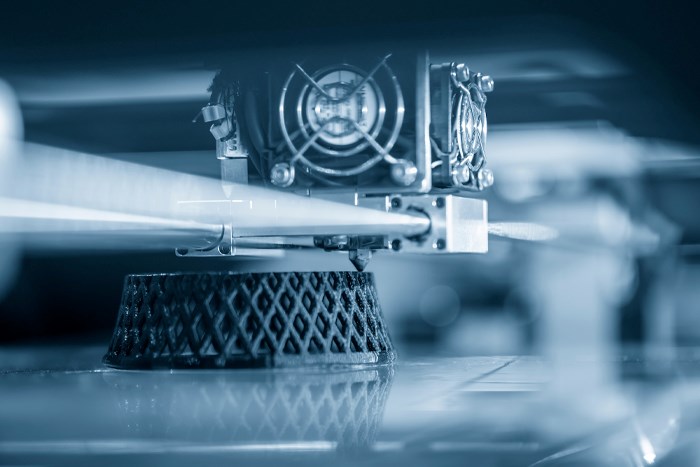

Xenia Materials reveals composite materials for FDM printing

A new range of 3D printing materials are formulated for use on any pellet-based fused deposition modeling printer.

Photo credit: Xenia Materials

Xenia Materials (Mussolente, Italy) has announced a new range of 3D printing materials, comprised of resins combined with chopped fibers and additives. The materials are made for use in any pellet-based fused deposition modeling (FDM) printer, for large-scale additive manufacturing (LSAM) as well as high-precision production.

Xenia will offer materials dedicated to 3D printing based on its existing range of product families: Xecarb, Xebrid, Xelight and Xegreen. The Xecarb 3DP brand includes carbon fiber-reinforced PEI, ABS and PC. Xebrid 3DP includes a glass and carbon fiber-reinforced ABS. Xelight 3DP includes a lightweight polyether block amide (PEBA), and Xegreen 3DP includes carbon fiber-reinforced PA6 and PA66. According to Xenia, the materials are recyclable and suitable for a wide range of applications and markets including industry, sport, sustainable mobility and defense.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Scaled Composites Model 437 aircraft to be flown for Beacon autonomy testbed

Northrop Grumman subsidiary part of Digital Pathfinder development of stealth aircraft with wings using continuous carbon fiber additive manufacturing and determinate assembly.