High-temperature polyimide and CMC composite structures

CAMX 2023: Composites Horizons LLC showcases capabilities in high-temperature composite structures and assemblies manufacturing, including polyimides and CMC.

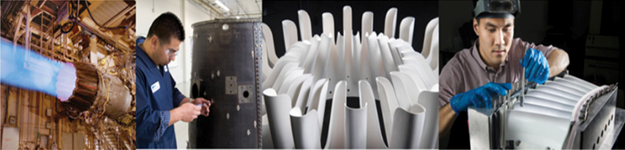

Photo Credit: Composites Horizons

Composites Horizons LLC (Covina, Calif., U.S.), a PCC Company, is a supplier of high-temperature composite structures and assemblies for the aerospace, defense and industrial industries. Supplying customers such as GE Aviation, Honeywell, Pratt & Whitney and Rolls Royce, the company offers lightweight, high-temperature structural composite solutions based on polymer matrix (polyimides) composites and oxide-based (ox-ox) ceramic matrix composite (CMC) materials.

Composites Horizons currently manufactures engine, duct and exhaust structures using PMR-15, PE-4 and RM1100 fiber-reinforced polyimide materials. These materials, which are capable of long-term operation (dry Tg of up to 750°F and a wet Tg of up to 570°F), are processed at high temperatures and pressures (up to 700°F and 200+ psi). With more than 25 years of experience in the processing of polyimide materials for aerospace, Composites Horizons has developed specialized tooling, layup and cure techniques to support the design of high-temperature components and assemblies that account for the distinctive processing characteristics of these materials.

Composites Horizons has been manufacturing ox-ox CMC at its 45,000-square-foot facility since 2014. The company supports the commercialization and adoption of these products via the development, characterization and demonstration of low-cost ox-ox CMC product forms (lower cost fabric-based prepregs) and automated tape layup of low-cost ox-ox tape materials. These developments offers the potential to reduce the cost of ox-ox CMC structures by up to 50% versus structures designed using traditional fabric-based ox-ox prepregs, the company contends.

The company’s Covina, Calif., U.S., facility consists of 160,000 square feet of manufacturing space and includes high-temperature/pressure autoclaves, material-specific cleanrooms, high-temperature presses and ovens, ceramic sintering furnaces, material-specific-dedicated cleanrooms, five-axis machining, coordinate measuring machine (CMM) equipment, nondestructive inspection (NDI) and assembly areas.

Related Content

-

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

-

Near-zero erosion ultra-high temperature CMC

K3RX commercializes UHTCMC for a wide range of markets, demonstrating performance in prototypes, assemblies and advancing manufacturing to reduce cost.

-

Bombardier begins manufacture of Global 8000 business jet

Ultra-long range business jet featuring CMC-intensive engine and a range of 8,000 nautical miles is set to enter service in second half of 2025 as it remains on track for flight testing.