Borealis highlights polypropylene technology for flexible automotive design

Fibremod, the customized carbon and glass fiber-reinforced polypropylene material ensures reduced weight, cost savings and design flexibility.

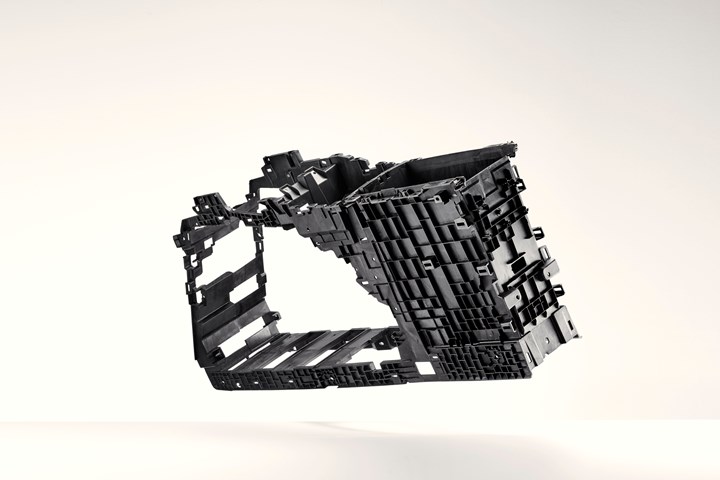

Center console automotive application using Fibremod. Photo Credit: Borealis

Borealis (Vienna, Austria), a supplier of polyolefin plastic materials for engineering applications in the automotive industry highlights the availability of Fibremod, its innovative carbon- and glass fiber-reinforced polypropylene (PP) technology, for the North American automotive market. The Fibremod family of customized products enables automotive manufacturers to achieve lighter weight and save on cost, says Borealis. Further, the company notes that replacing engineering plastics and metal parts with energy-efficient and lighter weight PP grades leads to improved fuel economy and lower CO2 emissions.

According to Borealis, products in the Fibremod family are a suitable material substitute for metal and engineered plastics, delivering unmatched design flexibility. Short-glass, long-glass and carbon fiber formulations are available, with customizable fiber content ratios, to enable manufacturers to balance strength, weight and cost according to specific design needs across applications ranging from front end and tailgate modules to instrument panel and center console carriers.

Fibremod products products also support energy efficiency in production by reducing process temperatures and energy requirements compared with alternative solutions such as polyamide (PA).

Related Content

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.