Bally Ribbon Mill develops advanced woven textile products

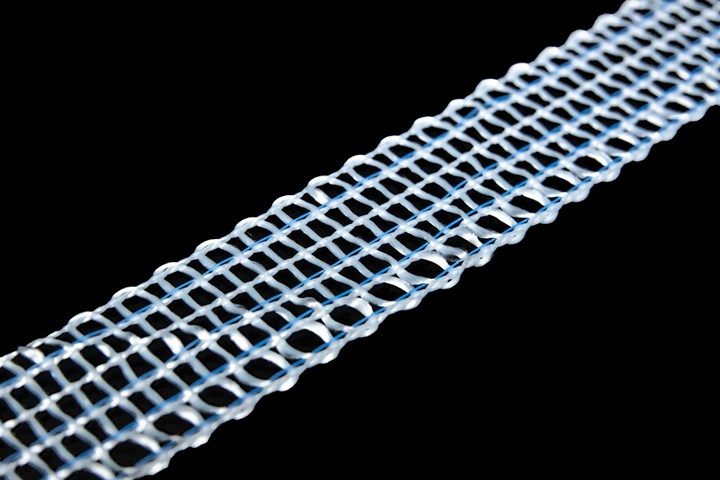

The company offers its woven E-Webbings and TPCM thermoplastic materials to increase part functionality and utility for a variety of industries.

Photo Credit: Bally Ribbon Mills

Bally Ribbon Mills (BRM, Bally, Penn., U.S.) a company that designs, develops and manufactures engineered woven fabrics, announces its new line of advanced textile products, E-Webbings and TPCM thermoplastic materials, to increase part functionality and utility. Both products offer lighter weight, specific strength, durability, stability, abrasion resistance and sustainability. According to the company, these materials are suitable for use as a preform in a “variety of composites manufacturing processes.”

E-Webbings are narrow fabrics that are conductive, enabling the electronic transmission of data sensations (light, noise, vibrations, heat), and power that can be stored or used to actuate/transform objects. The conductive fibers can be woven in conjunction with other fibers and can be used in embedded sensors in both wearable and integral technology, including the Internet of Things (IoT).

TPCM thermoplastic composite materials are 2D- or 3D-woven thermoplastic structures for incorporation into composite parts produced within varied, continually-evolving molding processes. The woven structural shapes are used in hybrid composite structures used in numerous industries, including aerospace, automotive, defense, infrastructure, marine and sports/recreation.

BRM is in accordance with safety standards, specifications and certifications, including ISO9001, AS9100, ISO13485, ISO14000, NFPA, ASTM, ANSI, *UL, and CSA.

Related Content

-

Troubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

-

Partners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.

-

Composites end markets: Sports and recreation (2025)

The use of composite materials in high-performance sporting goods continues to grow, with new advancements including thermoplastic and sustainability-focused materials and automated processes.