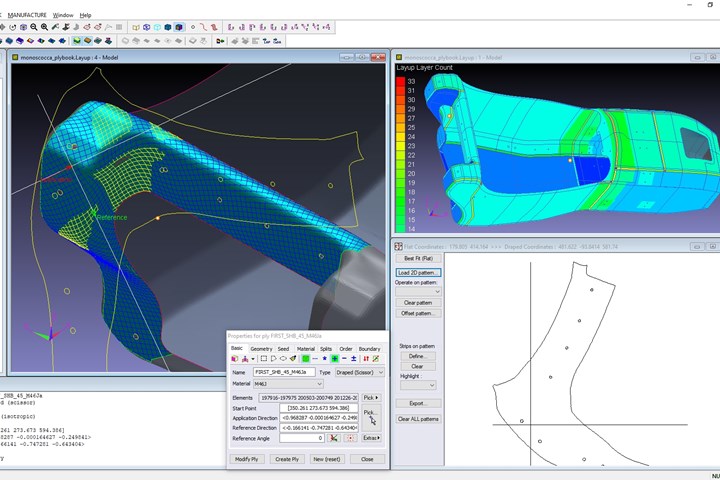

Anaglyph releases Laminate Tools version 4.10

Improvements include new algorithms, added support for Abaqus, Ansys Workbench add-ins and a faster, more reliable SolidWorks add-in.

Source | Anaglyph Ltd.

Composites structural design software specialist Anaglyph Ltd. (London, U.K.) has released version 4.10 of its Laminate Tools software application, delivering user-driven features in the Design, Analysis, Check and Manufacture modules, as well as in the user interface for composites structural design.

Anaglyph notes the considerable effort put in to speed up and enrich important functionalities that can save design time and build a better structural component, such as improving and extending interfaces to third-party partner products in both CAD and FEA domains. The company has also upgraded layup ply imports which now have fast/smart algorithms, supporting edge splits and seeds; added support for Abaqus 2020; the ability to export Abaqus solid mesh based on layup surface; Ansys Workbench add-in implementation; and a faster, more reliable SolidWorks add-in for plies with a large number of surfaces.

Laminate Tools is a stand-alone Windows application that addresses the entire geometry import-design-analysis-check-manufacture process of composites structural design. Used by composite structures designers and stress analysts in automotive, aerospace, marine, energy and leisure industries, it links the various disciplines, communicates original data between all involved in the process and conserves design time. Laminate tools also interfaces with most CAD and FEA applications, enabling for a flexible workflow.

Find a more comprehensive list of the software’s new features.

Related Content

-

Proving thermoplastic composites match carbon fiber/epoxy performance in road bikes

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

-

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

-

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.