University of Nottingham commissions resin metering system for short fiber compression molding

Slack & Parr’s precision external gear pumps enable the university’s EPSRC Future Composites Manufacturing Research Hub to precisely determine the fiber-to-resin ratio for their robot-mounted liquid resin spray system.

Slack & Parr's gear pumps are machined to extremely precise tolerances to deliver accuracy and control even at high pressure. Photo Credit: University of Nottingham, Slack & Parr

Precision metering pump specialist Slack & Parr (Derby, U.K.) has been commissioned by the University of Nottingham (U.K.) to supply its high-precision metering technologies as part of a short fiber compression molding system to manufacture composite parts for the automotive industry.

The short fiber compression molding approach has been developed by a team from the EPSRC Future Composites Manufacturing Research Hub at the University of Nottingham, led by Professor Nick Warrior and Dr. Anthony Evans. Their objective has been to develop an out-of-autoclave (OOA) manufacturing technology that accommodates lower cost, short fiber formats as a way of making composites more viable and cost-efficient and supporting the transport industry’s ambitions to become more fuel-efficient and sustainable. The solution is being used to manufacture components including complex-shaped under bonnet and suspension parts for automotive.

The university’s technology uses a liquid resin spray (LRS) system to apply the resin matrix to short form (25-millimeter) carbon fibers activated by an air stream. In this way, the resin and the fibers are said to make complete and uniform contact with each other without the need for mechanical application.

Professor Nick Warrior explains how Slack & Parr’s precision external gear pumps are key to the resin metering and spraying stages of the process: “Slack & Parr’s metering pumps allow us to control precise amounts of the resin’s constituent parts to achieve a matrix with the exact characteristics we need,” Warrior says. “Being able to accurately meter each ingredient means we can mix the resin matrix to a viscosity that can be sprayed reliably and effectively without having to rely on the overuse of solvents. Varying the percentages even slightly at this stage can result in a resin that may not spray or cure correctly, so accuracy is crucial here. We can also adjust the metering pump to create new resin systems with different characteristics, for example faster curing and better mould release to help us achieve our target 30-second cure cycle.”

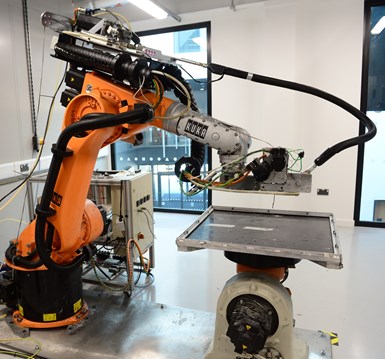

The University of Nottingham has developed a robot-mounted liquid resin spray system incorporating Slack & Parr's precision metering technology. Photo Credit: University of Nottingham, Slack & Parr

Slack & Parr’s metering pumps are built around hardened steel involute gears which are machined to precise tolerances of one or two microns. The company says this results in extremely small, controlled clearances — measuring less than a human hair — between the gear and mating components, ensuring almost no internal slip even at high pressures. This level of precision means the pump is able to control or meter the flow with extreme accuracy and repeatability.

In the university’s system, each part of the resin matrix is held separately to prevent curing and mixed only at the point of application. The metered matrix is then sprayed directly from the resin mixing tank onto the short form carbon fiber filaments which are simultaneously propelled into a controlled air stream via a robot head. The resin-coated carbon fibers are subsequently molded to form a composite component.

The University of Nottingham’s application requires three different fluids with different viscosities to be brought together at the same rate and in the right ratios to achieve the desired resin matrix and to ensure consistency and repeatability of the process. Using Slack & Parr’s gear pump technology, the university team was able to achieve a consistent flow throughout the process despite varying pressures linked to the different viscosities of the fluids.

“Our pump solutions are relevant to every area of the composites industry where the need to precisely determine the fiber-to-resin ratio is key to the manufacture of consistent composite materials and parts,” Neil Anderton, hydraulics and industrial director at Slack & Parr points out. “Importantly, the technology can also be extended out to other polymer resins and plastics to offer the same level of performance.”

Related Content

ADTC to celebrate grand opening for hands-on composites training

The training center’s launch, to include facility tours, demonstrations and networking opportunities, coincides with CAMX in Orlando.

Read MoreSAMPE launches 2026 Emerging Engineers Challenge

Early-career engineers are invited to submit design concepts by Dec. 8, focused on enhancing a manufacturing process using advanced materials, robotics, data analytics or machine learning.

Read MoreSAMPE 2025: Innovation, circularity and connection drive composites forward

Collaboration, workforce development and an ongoing focus on scalability and sustainability took center stage at SAMPE 2025 in Indianapolis.

Read MoreAltair, NIAR sign MOU to build aerospace innovation space

Collaboration will expand digital twin adoption, empower aerospace startups and speed up product development and certification processes.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More