TPRC project to develop structural analysis capabilities for overmolded parts

The ThermoPlastic composites Research Centre is working to develop an optimal process window for overmolding for both aerospace and automotive materials.

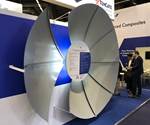

Source | TPRC

The ThermoPlastic composites Research Centre (TPRC, Enschede, the Netherlands) has announced it is currently finalizing its second project on overmolding, which will develop structural analysis capabilities for overmolded parts.

The process is simulated by combining AniForm’s (Enschede, the Netherlands) forming software and Autodesk’s (San Rafael, Calif., U.S.) Moldflow injection molding software with structural analysis software from Abaqus. A new geometry has been realized to characterize the interface under different loading conditions, which provides the input data to predict part performance in terms of stiffness and strength in the simulation. The research center says a new technology demonstrator has been developed.

The follow-up project on overmolding will start in October 2019 and will continue the organization’s work on structural analysis by developing an optimal process window for overmolding for both aerospace and automotive materials. In this multilateral project, external partners may join the project in addition to the TPRC members who are involved.

Related Content

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

-

MFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

-

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.