TPRC investigates AFP in-situ consolidation alternative

The two-step process involves deposition of thermoplastic prepreg via AFP, followed by vacuum-bag-only (VBO). Research has already been completed in the qualitative stage.

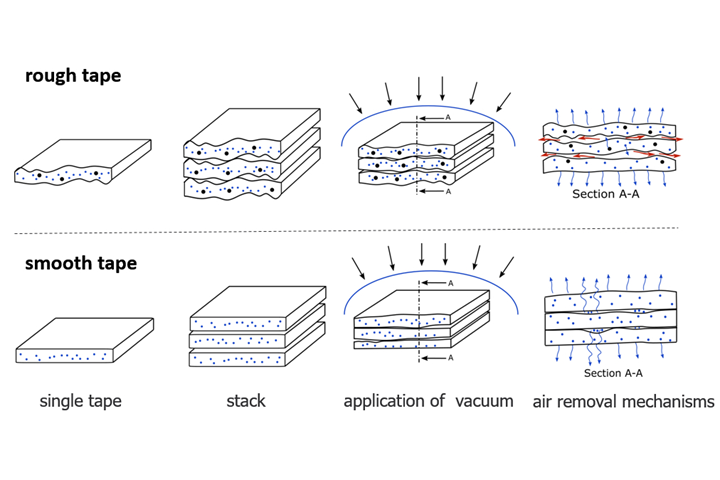

Figure 1. Different air removal mechanisms such as in-plane permeation and through-thickness diffusion for, respectively, rough tape (top) and smooth tape (bottom). Source | TPRC

The ThermoPlastics composites Research Center (TPRC, Enschede, Netherlands), is currently investigating a two-step approach for the manufacturing of thermoplastic composite structures, involving the rapid deposition of preimpregnated thermoplastic tape, using automated fiber placement (AFP) followed by vacuum-bag-only (VBO) consolidation. Compared to the AFP with in-situ consolidation alternative, TPRC says its AFP + VBO project combines the lay-down of tape material at a cost-effective rate and an affordable post-processing step to ensure the required consolidation quality.

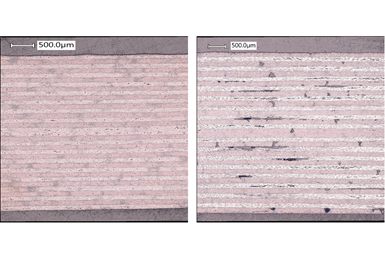

Figure 2. Laminates consolidated under vacuum pressure with free (left) and constrained (right) in-plane permeation; the latter was achieved by sealing off the laminate edges with tape. Source | TPRC

The main aim of the project, TPRC says, is to enable the cost-efficient out-of-autoclave (OOA) manufacture of advanced components by developing material guidelines and process models. This requires a thorough understanding of the physical mechanisms that control the OOA consolidation of fiber-placed thermoplastic laminates — for example, the in-plane permeation and diffusion of entrapped air during different stages of the consolidation process for various material configurations (Figure 1). TPRC says the mechanisms have been explored qualitatively, as seen through the effect of sealing the edges of a stack on air removal (Figure 2).

TPRC notes that the research is still ongoing, and measurement set-ups are being developed for the quantitative determination of both diffusion and permeation related material properties.

Related Content

-

Carbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

-

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.