Teijin sheds more light on Sereebo manufacturing process

Combining a chopped carbon fiber mat with nylon 6 resin, the process will be used to fabricate primary automotive structures in a forthcoming production vehicle.

Teijin (Tokyo, Japan) made public for the first time, at JEC World 2016 (March 8-10) in Paris, many details about its Sereebo high-volume composites manufacturing process. First announced in December 2011, the process was developed by Teijin in Tokyo and in cooperation with General Motors (GM) at Teijin's technology center in Auburn Hills, MI, US. Sereebo is designed specifically to meet the needs of the automotive industry to fabricate carbon fiber composite parts and structures at high volumes with short cycle times.

Eric Haiss, vice president of Teijin Advanced Composites America Inc. (Auburn Hills), told CW that the Sereebo process combines a nylon 6 resin matrix with a mat of chopped carbon fibers (length ~20 mm), which are preheated and then molded/formed in a standard compression molding machine in cycle times of 60-80 seconds. Haiss says Teijin cannot reveal the form the nylon 6 takes, except that it is integrated in the carbon fiber mat. In addition, the carbon fiber will be sized for the nylon 6 resin.

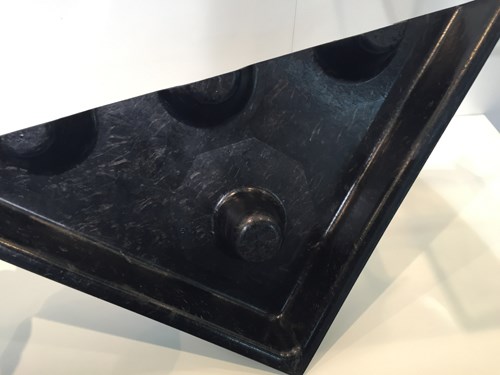

Parts on display in the Teijin stand at JEC indicate the Sereebo process is capable of producing parts with relatively deep draws and large curvatures, with no wrinkling (see images at left). In addition, changes in mat thickness allow for tailored fiber reinforcement to meet specific mechanical load requirements. Further, says Haiss, the way the fiber is oriented in the mat, isotropic properties can be moderately controlled.

Data displayed on the Teijin stand at JEC indicate that parts made with Sereebo exhibit significant energy-absorbtion properties: 70 J/g, compared to 59 J/g for continuous carbon fiber composites and 20 J/g for aluminum.

Haiss says the Sereebo process will be used by Teijin to fabricate primary structure automotive parts for an undisclosed automotive program. The model year of the vehicle was not revealed. Teijin also would not identify the OEM involved, but Teijin's history of cooperation with GM makes that carmaker the most likely customer. Fabrication will be done in the United States, but a location has not yet been determined. Haiss did say that fabrication will not be done in Auburn Hills.

Teijin is scheduled to discuss Sereebo at CompositesWorld's Thermoplastic Composites Conference for Automotive (TCCA), June 15-16, in Novi, MI, US.

Related Content

-

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.