Study reports INCA Renewtech hemp-based biocomposites radically reduce carbon emissions

Compared to lauan rainforest plywood, INCA’s BioPanels are reported to reduce carbon emissions, waste production and water consumption.

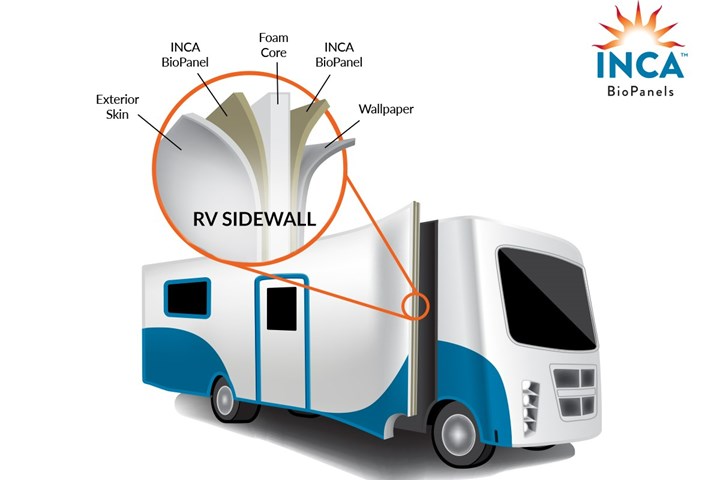

Natural fiber composites manufacturer INCA Renewable Technologies (Kelowna, Canada) reports that its lead product, INCA BioPanels, will reduce carbon emissions by 76%, waste production by 89% and water consumption by 82% compared to the lauan rainforest plywood currently used by recreational vehicle (RV), furniture and motion picture industries. INCA says the results were published in a Product Life Cycle Analysis conducted by GreenStep Solutions, an independent research and certification organization.

INCA’s Chairman and CEO, David Saltman says, “We believe economic performance, social responsibility and environmental integrity are metrics of success. We’re encouraged that this important research study affirms the value of our innovative products in combating climate change.”

INCA says the findings were part of an in-depth research analysis focused on carbon emissions, water consumption and waste for six of the hemp-based products the company will be producing versus conventional alternatives.

Other key takeaways from the study included:

- 1 cubic foot of INCA’s BioPlastics when compounded with recycled polypropylene will reduce carbon emissions by 91% and water consumption by 59% compared to glass fiber-reinforced plastics (GRP).

- 1 cubic foot of INCA’s BioPlastics when compounded with polylactic acid (PLA) resin will reduce carbon emissions by 23%, waste production by 68% and water consumption by 18%.

- 1 week of INCA’s BioBedding for horses will reduce carbon emissions by 323% versus wood chips

According to INCA, the GreenStep research study included consideration of formulations, raw material extraction and processing, energy and water inputs, product manufacturing and fuel consumption at each stage of the process including downstream transportation and distribution.

Not considered by the study, INCA notes, were the impact of industrial hemp farming, which INCA says has been shown in multiple studies to capture eight to fifteen tonnes of CO2 per hectare of cultivation, nor packaging, subsequent manufacturing, distribution and storage or end-of-life. INCA adds that its BioPlastics with polylactic acid resin will be recyclable, biodegradable and compostable. INCA’s BioBedding will be biodegradable and compostable.

In August, INCA announced it had secured the land to build a large-scale manufacturing facility in Elkhart County, Indiana that will process thousands of tons of hemp fiber into high performance bio-composite panels and pellets for the transportation, consumer plastics and building materials industries. INCA also announced an exclusive sales agreement to produce bio-panels for RVs and trucks with Genesis Products, which provides design and engineering, advanced materials expertise and manufacturing facilities to Fortune 200 companies in the RV, building materials, transportation and furniture industries.

Read more about the company at “Industry veterans form new company to produce next-gen natural fiber composites.”

Related Content

-

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

-

Moving toward sustainable automotive parts manufacturing

How can the automotive supply chain prepare for future sustainability requirements? Tier 1 Kautex Textron discusses emissions reduction, design for circularity and transition to recycled/bio-based plastics.

-

European boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

.jpg;width=70;height=70;mode=crop)