Industry veterans form new company to produce next-gen natural fiber composites

With deep roots in agricultural hemp production, INCA Renewable Technologies is set to produce lighter, stronger, greener and less costly composites.

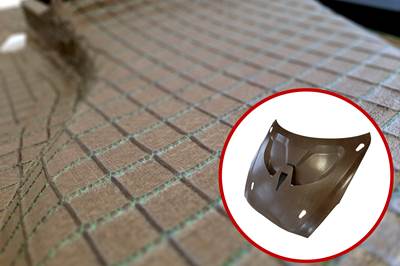

A new type of hemp fiber-reinforced composite panels, initially targeted at the recreational vehicle (RV) and truck trailer markets, will be produced by INCA Renewable Technologies Inc. in its new facility in Elkhart, Ind., U.S. and supplied to Genesis Products Inc. for finishing and installation in RVs. Photo Credit: Genesis Products Inc.

A team of North American composites industry veterans have formed a new company, INCA Renewable Technologies Inc. (Kelowna, B.C., Canada), that aims to produce natural fiber-reinforced composites (and other green technologies) to solve longstanding industry challenges.

INCA recently closed on property in Elkhart, Ind., U.S., the global epicenter of recreational vehicle (RV) production, that will house the company’s production-scale line to produce natural fiber composite panels “produced in a non-traditional manner.” The panels will be manufactured on a large press line said to be capable of producing sheet-form composites in the world’s largest width — measuring 317.5 centimeters/124 inches after trimming — to produce B-staged composites with a proprietary resin system capable of fiber volume fractions (FVFs) up to 70% (versus the maximum 50% FVF typical of nonwovens). In turn, panels can be finished and used directly, after applying aesthetic and functional surfaces to one or both sides, to produce sidewalls, floors and roofs for RVs and truck trailers. Or, materials can be compression molded into 2.5D structural or semi-structural parts for use in industries like automotive, sporting goods and consumer products.

INCA also reports it has developed a flame-retardant system for the composites that is expected to pass stringent flame/smoke/toxicity (FST) tests in industries like rail and aircraft. The same facility will also produce clean chopped (6-9-millimeter) hemp fiber that INCA will custom compound into injection moldable thermoplastic pellets in a variety of resin chemistries. Furthermore, INCA has signed an exclusive sales agreement with Elkhart-based Genesis Products Inc., which designs, engineers and manufactures a range of products for the RV, building/construction, transportation and furniture markets.

Although it claims to be natural fiber (and resin) agnostic, an interesting aspect of INCA’s value proposition is the company’s deep roots in agricultural hemp production — not only in Latin America, from whence Peruvian-born Christopher Schwarz, INCA board member and VP Latin operations hails, but also in North America.

“Hemp is a low-cost but high-tensile strength fiber that makes very light composites with excellent mechanical properties,” explains natural fiber composites guru, Garry Balthes, INCA president and chief technology officer. “We’re providing hemp farmers with ancillary income for parts of the plant they currently throw away and creating a 100% off the field value chain — a win/win for everyone.” Balthes says the hemp fiber will be cleaned, carded and bailed near to where it’s grown, then shipped to Elkhart for sorting and processing into “bio-panels” and thermoplastic pellets.

“In previous businesses, we imported natural fiber from India and Bangladesh, but there were often supply problems,” continues David Saltman, INCA chair and CEO. “If the last year taught us nothing else, it’s the fragility of long global supply chains. Fortunately, since the 1990s, hundreds of thousands of acres of hemp have been planted on the Canadian prairies, and more recently it’s been grown in the U.S., so we have access to a ready supply for North American customers.”

“We’re currently going through a lifecycle analysis and certification process and hope to be able to supply customers with certified, carbon-negative composites reinforced with regionally sourced hemp fibers,” adds Karl Nicholas, INCA VP business development. “Our customers in the RV and truck trailer industries will benefit from stronger, lighter, greener panels that are actually structural.” INCA reports that unfinished oriented strand board (OSB) panels typically used in the RV industry, average 5,400 grams/square meter (GSM) whereas their own product will run 3,800 GSM — a 30% mass savings in a product that won’t off-gas styrene or formaldehyde, or be prone to harboring mold/mildew as OSB does. Commercial production is expected to start in 2024.

Related Content

Bcomp ampliTex makes appearance in Cupra EV Cup Bucket seats

The entire Cupra Born VZ line-up features all-natural fiber front seats that highlight functionality, aesthetics and reduced CO2 emissions.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreNASCAR unveils BEV prototype featuring natural fiber bodywork

Implementation of Bcomp technical flax fibers in a U.S. motorsport first represents NASCAR’s step toward more sustainable competition vehicles.

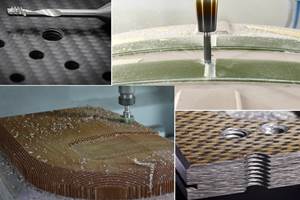

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreRead Next

Composites Evolution, Bcomp launch Evopreg ampliTex flax-epoxy prepregs

Compatible with Bcomp’s powerRibs reinforcement grid, the family of natural fiber materials drives enhanced stiffness, lightweight and a reduced footprint for motorsports and high-performance automotive applications.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More

.jpg;width=70;height=70;mode=crop)