SIU researcher to apply additive manufacturing for more efficient sandwich material production

Southern Illinois University’s Sabrina Nilufar won a two-year, $200,000 grant from the NSF to study how to make composite sandwich panels with a TPMS-based core lattice via AM.

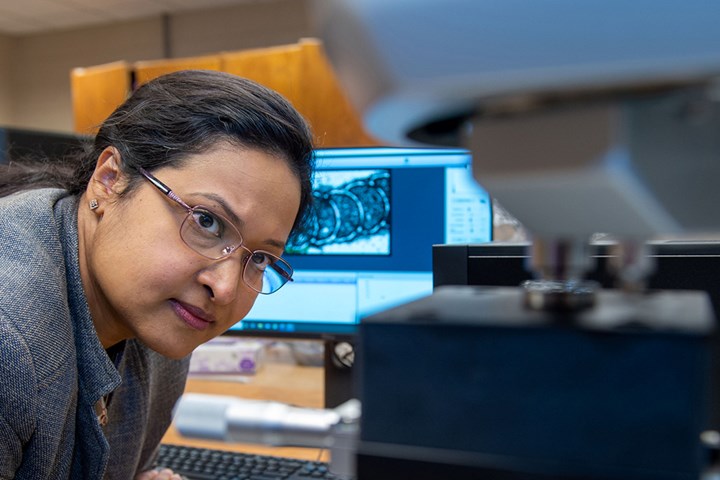

Sabrina Nilufar, assistant professor in the SIU School of Mechanical, Aerospace and Materials Engineering, is working on ways to more easily and efficiently construct composite “sandwich” materials used in everything from automotive to marine and aerospace applications. She recently received a two-year, $200,000 grant from the National Science Foundation to study how to make specially designed structures built using additive manufacturing (AM). Photo Credit: Russell Bailey

Sabrina Nilufar, an assistant professor at the Southern Illinois University (SIU, Carbondale) School of Mechanical, Aerospace and Materials Engineering, is working on ways to more efficiently construct ultra-strong “sandwich” materials, while also improving time and energy savings. She recently received a two-year, $200,000 grant from the National Science Foundation (NSF, Alexandria, Va., U.S.) to study how to make sandwich panels — specifically, carbon fiber-reinforced face sheets with a triply periodic minimal surface (TPMS) architecture — using additive manufacturing (AM).

According to Nilufar, TPMS architecture uses complex geometries found in nature to improve strength and weight ratios. “The aim of my research is to set a solid foundation of manufacturing sandwiches with TPMS-based core lattice for specific engineering applications,” Nilufar says.

Sandwich structures generally consist of two outer face sheets separated by a lightweight, low-density core structure or foam. The engineering concept has found its way into myriad applications, including aerospace, sport, marine, military, thermal insulation, vibration and acoustic isolation, and automotive parts.

The traditional manufacturing process for sandwich materials, however, can be wasteful and limited, Nilufar notes, particularly concerning what’s between the face sheets. The topology of the sandwich’s middle, or core, has a major impact on the overall performance of the structure, in terms of weight, strength, thermal properties and other factors. Depending on the core’s geometry, such factors can be improved or diminished in function, and while engineers have theorized about new core structures, the manufacturing process has posed limitations. In contrast, using AM enables the fabrication of objects or customized tailored parts with complex geometry directly from the 3D models.

Working in her laboratory at SIU, Nilufar hopes to reveal the mechanisms and thermomechanical properties of various core structures that can be created with TPMS architecture, particularly on core lattice geometries, such as gyroid, diamond and primitive core structures. Her approach will integrate numerical and experimental methods to find out what manufacturers might achieve using additive processes.

As part of the effort, her research team will develop 3D models to predict thermomechanical properties for various core topologies. The work will identify high-stress and critical sections of various structures and look at how to optimize factors such as the size of each cell and wall thickness. The team also will examine how and why TPMS structures deform under various loads and temperatures. Along those lines, Nilufar and others will use an electron microscope to look closely at surface morphology and failure mechanisms.

“We want to fundamentally understand how structured core lattice architecture improves the mechanical and thermal properties of sandwich structures,” Nilufar says. “We hope the project helps us gain new understandings of how these forces would impact TPMS structures in the real world.”

Nilufar’s work will involve multiple disciplines, including engineering mechanics, materials science and AM. The grant will support the research of both graduate and undergraduate students — a key feature of SIU’s student experience — and encourage participation by underrepresented minorities in science and engineering. Moreover, the local outreach component of the project will demonstrate research concepts to high school and middle school students, planting the seeds for future engineers.

Related Content

Aviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

Read MoreFilament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreRead Next

Ultrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More