Rolls Royce launches Pearl family of engines

The Pearl 15 is the first of the planned Rolls-Royce’s Pearl engine family, which will be used for Bombardier’s Global 5500 and Global 6500 business jets.

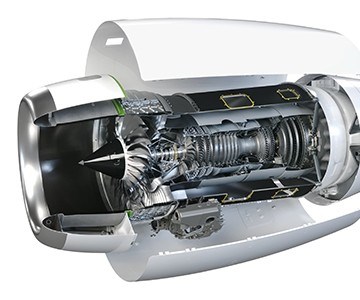

Rolls-Royce (London, UK) announced on May 28 the launch of a new engine family for business aviation, with the introduction of the Pearl. The engine will be used for Bombardier’s latest business jets, the Global 5500 aircraft and the Global 6500 aircraft. The Pearl 15 is the first of the planned Pearl engine family for business aviation and marks the sixth new civil aerospace engine introduced by Rolls-Royce in the past 10 years.

The Pearl engine combines technologies derived from Rolls-Royce’s Advance2 technology demonstrator programmes with proven features from the Rolls-Royce BR700 business aviation engine family. The engine employs composite materials for the engine’s bypass duct, the nacelle and the brand-new hybrid light-weight drive shaft. The composite drive shaft is a key enabler for the new high-speed core engine and has been developed in cooperation with Rolls-Royce’s global University Technology Network (Dresden, Germany and Bristol, UK).

The new engine, which was developed at Rolls-Royce’s Centre of Excellence for Business Aviation engines in Dahlewitz, Germany, received EASA certification on Feb. 28. The engine is currently undergoing flight tests at Bombardier’s Flight Test Centre in Wichita, KS, US and has a planned entry into service at the end of 2019.

Related Content

-

The next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

-

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.